Kawasaki Heavy Industries - Experts & Thought Leaders

Latest Kawasaki Heavy Industries, Ltd. news & announcements

ClassNK has issued an Approval in Principle (AiP) for a parcel layout concept for a hydrogen-fueled multi-purpose vessel developed by Mitsui O.S.K. Lines, Ltd., MOL Drybulk Ltd., Onomichi Dockyard Co., Ltd., Kawasaki Heavy Industries, Ltd., and Japan Engine Corporation. This is the world’s first AiP certification for a ship equipped with a large low-speed two-stroke hydrogen-fueled engine as the main propulsion engine. Growth and building of the vessel According to the companies, demonstration operation of the vessel will be conducted for two years from around FY2027 as part of the “Development of marine hydrogen engines and MHFS,” which was adopted by the Green Innovation Funding Programme of the New Energy and Industrial Technology Development Organisation (NEDO). MOL and MOL Drybulk will be in charge of right and process management of the vessel Prior to the demonstration operation, J-ENG’s large low-speed two-stroke hydrogen-fueled engine and Kawasaki’s MHFS will be installed in the vessel by FY2026. MOL and MOL Drybulk will be in charge of ownership and operation management of the vessel and Onomichi Dockyard will be in charge of the development and building of the vessel, and they will cooperate towards the demonstration operation. Risk assessment results ClassNK carried out a review of a parcel layout concept for the MHFS based on its rules including part GF of its "Rules and Guidance for the Survey and Construction of Steel Ships" incorporating the IGF Code and risk assessment results through pre-HAZID. Upon confirming they comply with the prescribed requirements, ClassNK issued the AiP. ClassNK will contribute to the further consideration of the project for demonstration operation from the perspective of safety evaluation and will strive to support the decarbonisation of shipping.

Tokyo-based Classification Society – ClassNK has issued an Approval in Principle (AiP) for a dual fuel generator engine using hydrogen gas as fuel and related machinery systems and arrangements for a 160,000 m3 liquefied hydrogen carrier developed by Kawasaki Heavy Industries, Ltd. (KHI). This marks ClassNK’s first AiP for a dual fuel generator engine using hydrogen gas as fuel. As hydrogen is expected to be used as a clean energy source to realise a decarbonised society, ClassNK has worked on the establishment of necessary standards and certification to contribute to its maritime transportation and marine fuel use. ClassNK issues AiP for design of liquefied hydrogen carrier ClassNK carried out the design review of the dual fuel generator engines using hydrogen gas as fuel For the 160,000 m3 liquefied hydrogen carrier developed by KHI, ClassNK has so far issued AiPs for its integrated design, as well as its Cargo Containment System (CCS), Cargo Handling Systems (CHS), and dual fuel main boilers that use hydrogen boil-off gas as fuel. In the latest examination, ClassNK carried out the design review of the dual fuel generator engines using hydrogen gas as fuel and related machinery systems and arrangements, based on its Part N of Rules for the Survey and Construction of Steel Ships incorporating the IGC Code, and its Guidelines for Liquefied Hydrogen Carriers incorporating the IMO’s interim recommendations for Carriage of Liquefied Hydrogen in Bulk. Comprehensive safety assessment conducted In addition, a comprehensive safety assessment was conducted based on the HAZID risk assessment results, which has led to the issuance of the Approval in Principle (AiP). According to Kawasaki Heavy Industries, Ltd., the dual fuel generator engine is capable of switching between hydrogen and low-sulfur fuel oil flexibly, and when hydrogen fuel is selected, boil-off gas naturally evaporated from the ship’s liquefied hydrogen cargo tanks is used as the main fuel at a calorie - based mixed ratio of 95% or higher to generate and supply electricity in board, which is expected to reduce greenhouse gas emissions from the ship significantly. Support decarbonisation of the entire maritime industry ClassNK will actively continue to take part in advanced initiatives toward decarbonisation ClassNK will actively continue to take part in advanced initiatives toward decarbonisation and also support the decarbonisation of the entire maritime industry, by incorporating the knowledge gained through collaboration with front runners into rules and guidelines. Approval in Principle (AiP) At the initial stage of designing or before the specific target ship etc. to be implemented is decided, the design is examined based on the existing regulations, such as international treaties and ship classification rules, and an Approval in Principle (AiP) is issued as proof of conformity with requirements. Approval in Principle (AiP) also prevents rework of regulatory aspects in the post-process, shortens the examination time at the time of class registration, and can be used as a technical basis for external appeal of the design status.

WE Tech solutions has received a new order to deliver its Economical Operations Solution to a series of two 86,000 cbm LPG carriers. The vessels are to be built for the Japanese shipping company NYK Line at Kawasaki Heavy Industries in Japan. The Contract was facilitated by The China & Japan Marine Industries Limited. The equipment delivery from WE Tech will commence in January 2023. The Economical Operations Solution package includes the Direct Drive Permanent Magnet Shaft Generator and a WE Drive. The solution delivers the highest electrical efficiency available on the market, resulting in reduced fuel consumption and reduced emissions for optimal environmental sustainability. Reducing environmental footprint “Our solution will bring significant savings in terms of operation performance and fuel consumption. With reduced fuel consumption the environmental footprint will also be reduced. We are proud to contribute to a sustainable future of shipping.” said Mr. Martin Andtfolk, Sales Manager of WE Tech Solutions. Fuel cost savings WE Tech’s supply for the NYK Line’s vessels include engineering, project management, and after-sales services In Power Take Out (PTO) mode, the vessel’s electrical power will be supplied from the Direct Drive Permanent Magnet Shaft Generator via the WE Drive and thus the Auxiliary Generators can be stopped. Significant savings in fuel cost is achieved from electrical power generation by the slow speed Main Engine which has far better efficiency in comparison to the Auxiliary Generator sets. Further savings are achieved by reduced operating hours and hence significantly reduced need for maintenance of Auxiliary Generators. Energy-efficient solution provider “WE Tech is rapidly expanding our business on a global scale as the leading energy-efficient solution provider. I am glad that WE Tech has now reached Japan–one of the biggest shipbuilding markets!” says Mr. Mårten Storbacka, Managing Director of WE Tech Solutions. “WE Tech is proud to be the market leader in delivering variable speed shaft generator solutions. Our solutions surpass everyone else in terms of reliability and energy efficiency. We strongly believe that our innovative solutions are leading the way into the future of variable speed power generation in the shipping industry.” WE Tech’s full scope of supply for the NYK Line’s new vessels also includes engineering, project management, commissioning, and after-sales services.

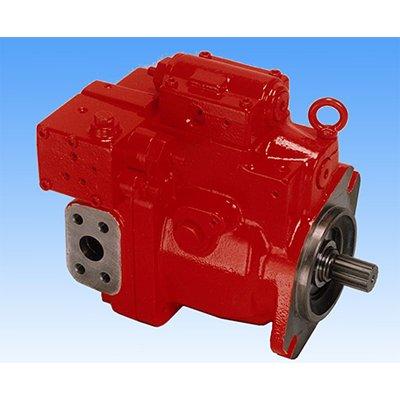

Kawasaki Heavy Industries K3VL 28 Axial Piston Pumps (Open Loop)

Kawasaki Heavy Industries K3VL 45 Axial Piston Pumps (Open Loop)

Kawasaki Heavy Industries K3VL 80 Axial Piston Pumps (Open Loop)