Skills

Inmarsat Maritime, a Viasat company, has announced Caribe Tankers USA, Inc (CTU) will trial Inmarsat’s fully managed bonded connectivity service, NexusWave, on board the chemical tankers Caribe Maria and Caribe Luna: as the US-based company seeks an ultra-reliable solution to best serve operational and crew connectivity. By combining multiple network underlays in one fully managed, bonded solution, Inmarsat’s NexusWave enables applications to leverage the aggregate capacity of all a...

In a landmark event, a meticulously reconstructed 5th-century wooden stitched ship was launched into the waters of the Mandovi River in Goa. This endeavour, a collaborative effort between the Ministry of Culture, the Indian Navy, and Hodi Innovations Pvt. Ltd., signifies a monumental step in reviving India's ancient maritime traditions. Modern stability and strength needs IRS has been instrumental in this project, ensuring that while the vessel retains its historical design Indian Register o...

The English Commercial Court (the “Court”) has provided helpful clarity on the extent of damages available to a claimant shipowner for the late redelivery of a vessel under a time charter where there is evidence that the owner of the vessel would have been unable to enter into a subsequent charter for the vessel. In such circumstances, only nominal damages will be recoverable, as no actual loss has been suffered. Background Hapag-Lloyd AG (the “Charterers”) entered i...

In recognition of its exceptional achievement in maintaining a safe work environment, the National Safety Council (NSC) presented ABS with two safety awards. The NSC is a globally recognised nonprofit organisation committed to eliminating leading causes of preventable death and injury in the workplace and on roadways. Their awards program recognises organisations and individuals who have made significant contributions to upholding the safety of their workplaces and communities. ABS’ acco...

On the occasion of its 50th Foundation Day on 4th April 2025, the Indian Register of Shipping (IRS) achieved a remarkable milestone by setting an Indian record for the ‘Largest Corporate Flag made on cloth’, as recognised by the India Book of Records. The massive flag, measuring 60 feet by 40 feet, was unfurled within the IRS Head Office premises. Adorned with the organisation’s logo, emblem, and corporate colours, the flag stands as a bold and symbolic representation of...

Transport Secretary, Heidi Alexander, said: “Today we mark significant progress in our journey to creating a greener, cleaner planet with a landmark agreement at the International Maritime Organization." “We have worked closely with international partners to forge a path for sustainable shipping internationally and secure a prosperous, resilient sector, laying a strong foundation for the future." Development of clean fuels Alexander added: “This deal means t...

News

Fincantieri, a pioneer in complex shipbuilding, and Accenture, one of the world’s pioneering professional services companies, have signed an agreement to establish Fincantieri Ingenium, a new joint venture. The company will be owned 70% by Fincantieri NexTech – a subsidiary of the Fincantieri Group – and 30% by Accenture. The initiative stems from a Memorandum of Understanding signed in July 2024 and combines Fincantieri’s technological expertise in the naval sector with Accenture’s advanced digital capabilities and digital engineering and manufacturing expertise. The project is subject to customary regulatory clearances. Fincantieri Group’s Industrial Plan Fincantieri Ingenium has been created to accelerate digital transformation across the cruise industry Fincantieri Ingenium has been created to accelerate digital transformation across the cruise, defence, and port infrastructure sectors. It will play a key role in executing the strategy outlined in Fincantieri Group’s Industrial Plan. The goal is to enhance the offering of digital services and systems based on recent advances in technologies such as artificial intelligence by optimising the entire value chain through data utilisation and process transformation. Accenture’s extensive experience in digital platforms The joint venture will integrate Accenture’s extensive experience in digital platforms, AI, connectivity and IoT, cybersecurity, and service design with Fincantieri’s deep technological know-how in the naval and defense industries. This powerful combination will enable the development of new technological capabilities and skills, while also attracting and training new talent. Next-generation ships and existing fleets The first ship equipped with Navis Sapiens is expected to enter service by the end of 2025 Among the first strategic initiatives of the new company is the development of Navis Sapiens, a digital ecosystem designed for next-generation ships and the upgrade of existing fleets. The project spans three key dimensions: the creation of a portfolio of application services to optimise operational efficiency and lifecycle management for ships and onshore infrastructure; the development of a digital platform enabling these applications and advanced AI-driven functionalities, with a strong focus on cybersecurity; and a marketplace to facilitate the exchange of solutions - including those from third parties - to deliver high value-added services and enable new business models across the maritime ecosystem. The first ship equipped with Navis Sapiens is expected to enter service by the end of 2025. Ships and onshore ecosystems In synergy with Navis Sapiens, the joint venture also plans to enhance real-time data exchange and connectivity between ships and onshore ecosystems - including ports and shipyards - through a sea-to-shore interoperability solution to increase cross-functional process efficiency. This project will help improve the competitiveness of Italian ports by optimising performance across the entire maritime and land-based value chain. National maritime ecosystem The plans will be designed to reduce environmental impact via data-driven energy optimisation All initiatives will be promoted with sustainability as a core pillar. The systems will be designed to reduce environmental impact through data-driven energy optimisation, supporting shipowners in reducing fuel consumption. The initiatives already underway, as well as those to come, will generate significant value for Fincantieri, the national maritime ecosystem, and the country as a whole, with a positive impact on a global scale. Fincantieri technological innovation Pierroberto Folgiero, CEO and General Manager of Fincantieri, said: "With Fincantieri Ingenium, we strengthen our leadership position in technological innovation applied to shipbuilding and the naval engineering industry. This joint venture represents a strategic step forward in accelerating the digitalisation of the sector, leveraging artificial intelligence and the most advanced technologies." "Thanks to the synergy with Accenture, we will develop cutting-edge solutions that will make our ships and infrastructures increasingly connected, efficient and sustainable, consolidating Fincantieri's role as a pioneer in the sector." Step forward in maritime innovation Teodoro Lio, MU Lead for ICEG and CEO of Accenture Italy, commented: “We are excited about this joint venture with Fincantieri, which marks a significant step forward in maritime innovation and is a tangible example of collaboration between two organisations committed to transforming the market and creating new value." "With Fincantieri Ingenium, we are combining our respective strengths to shape new operating models that will transform maritime operations through innovative technologies.”

Technology group Wärtsilä has introduced a new methane slip reduction solution for its Wärtsilä 50DF dual-fuel engine. The new technology, which converts Wärtsilä 50DF dual-fuel (DF) engines to spark gas (SG) operation, enables a more optimised combustion process, thereby improving efficiency and lowering methane emissions. Wärtsilä 50DF engine Whilst operating on LNG, the new ‘Spark Gas Conversion for Wärtsilä 50DF’ is designed to reduce methane emissions up to 75 percent more than the standard Wärtsilä 50DF engine. The Spark Gas Conversion for Wärtsilä 50DF minimises methane emissions by introducing an electrically controlled pre-combustion chamber valve for a more optimised combustion process. Use of LNG and cutting methane emissions New solution reduces methane emissions down to 1.1 percent of fuel use The estimated result is that, on an IMO weighted (E2-cycle) average, the new solution reduces methane emissions down to 1.1 percent of fuel use. “The use of LNG and cutting methane emissions is one of the most effective ways to decrease overall greenhouse gas (GHG) emissions from marine engines over the next decade, complementing other efforts to reduce CO2 emissions,” comments Roger Holm, President of Wärtsilä Marine & Executive Vice President at Wärtsilä Corporation. “As the shipping industry strives for more sustainable operations, this new solution represents an important milestone on the road to advancing lower carbon fleets.” Chevron LNG Carriers The development of the solution, which consists of converting one-to-two of the total DF engines to SG, was made possible through extensive collaboration between Wärtsilä and Chevron Shipping Company. It was announced earlier that one engine on six Chevron LNG Carriers will be converted from DF to SG as part of Chevron’s aim to reducing the carbon intensity of its operations. Lower methane emissions The new solution is optimised for LNG as fuel, thus producing a better power work per unit of fuel The solution is now available to all vessels in the industry with existing Wärtsilä 50DF engines diesel-electric propulsion, the majority of which are LNG carriers. The new solution is optimised for LNG as fuel, therefore producing a better energy output per unit of fuel. This means fuel gas savings of up to 4.6 percent, as well as lower methane emissions. LNG-fuelled engines Holm continues: “Wärtsilä has an extensive track-record in reducing methane slip from LNG-fuelled engines, not only as newbuild solutions, but also through retrofitting existing installations. This latest technology complements our extensive portfolio of solutions aimed at reducing methane emissions from vessels.” With three decades of experience in LNG technology, Wärtsilä is providing market-pioneering performance-both with the dual fuel flexibility provided by the DF engine, as well as with the single fuel SG engine.

Hefring Marine, an Icelandic pioneer in intelligent marine technology, and Marine AI, a UK-based pioneer in autonomous vessel control systems, announced a new mutually beneficial partnership. This collaboration aims to enhance autonomous maritime operations by integrating Hefring Marine’s Intelligent Marine Assistance System (IMAS) with Marine AI’s GuardianAI autonomy suite. Hefring Marine’s IMAS Hefring Marine’s IMAS will complement GuardianAI’s existing capabilities by providing real-time insights This partnership sets the stage for seamless technological integration, where Hefring Marine’s IMAS will complement GuardianAI’s existing capabilities by providing real-time insights into sea conditions, optimising vessel operations, and improving safety. The collaboration will ensure that IMAS is fully compatible with the GuardianAI marine autonomy stack, with future plans to offer IMAS as an OEM-supported module within the GuardianAI suite. Integrating IMAS with GuardianAI “Our new venture with Marine AI is a great win for autonomous maritime technology,” said Karl Birgir Björnsson, CEO of Hefring Marine. “By integrating IMAS with GuardianAI, we are enabling vessels to operate more efficiently, safely, and with greater situational awareness. This partnership is a testament to our commitment to enhancing fleet intelligence and optimising maritime operations.” IMAS leverages AI technology Hefring Marine’s IMAS leverages AI technology, sensor data, and edge computing to insights Hefring Marine’s IMAS leverages AI technology, sensor data, and edge computing to deliver actionable insights, improving vessel efficiency, reducing fuel consumption, and enhancing onboard safety. Marine AI’s GuardianAI is a modular, state-of-the-art autonomous vessel control system capable of IMO Level 4+ autonomy, enabling high-fidelity situational awareness, tactical path routeing, and intelligent vessel control. How autonomous vessels interact with their environments “The synergy between GuardianAI and IMAS will redefine how autonomous vessels interact with their environments,” said Tom Rooney, general manager of Marine AI. “IMAS acts as the ‘human feel’ in an autonomous setting, allowing vessels to respond dynamically to real-time conditions. This partnership enables a holistic approach to autonomy, ensuring both crewed and uncrewed vessels can navigate safely and efficiently.” Focus on key maritime sectors Partnership will provide enhanced situational awareness and improved vessel in sea conditions This partnership will focus on key maritime sectors, including rescue operations, law enforcement, defense, offshore support, crew transfer and the leisure industry. By integrating IMAS within GuardianAI, the partnership will provide enhanced situational awareness and improved vessel survivability in various sea conditions. Capabilities of autonomous vessel operations Future plans include ongoing joint product development and system enhancements to expand the capabilities of autonomous vessel operations. The scalable nature of this technology means it can be applied across a broad spectrum of vessel types, from small uncrewed autonomous vessels to large passenger ships.

ClassNK has issued an approval in principle (AiP) for an Onboard Carbon Capture and Storage system (OCCS) developed by Mitsubishi Shipbuilding. The certification confirms its feasibility from regulatory and safety perspectives. Interest in CO2 capture the method from exhaust gases is growing alongside fuel conversion as part of efforts to reduce GHG emissions from ships. In response, the development of OCCS is progressing. Safety requirements for OCCS ClassNK will often strive to contribute to advanced decarbonisation initiatives via safety assessments To support the smooth development and introduction of related technologies, ClassNK has published the 'Guidelines for Shipboard CO2 Capture and Storage Systems' as a subset of the ClassNK Transition Support Services. This guideline outlines safety requirements for OCCS and its installation on ships. ClassNK reviewed the design of the system based on 'Guidelines for Shipboard CO2 Capture and Storage Systems'. Upon confirming compliance with the prescribed requirements, ClassNK issues an AiP. ClassNK will continually strive to contribute to advanced decarbonisation initiatives through safety assessments and more. Approval in Principle (AiP) At the initial stage of designing or before the specific target ship to be implemented is decided, the design is examined based on the existing regulations such as international conventions and ship classification rules, and an Approval in Principle (AiP) is issued as proof of conformity with requirements. It also prevents rework of regulatory aspects in the post-process, shortens the examination time at the time of class registration, and can be used as a technical basis for external appeal of the design status.

Brunvoll has signed a contract with Rizhao Gangda Shipyard for the delivery of an extensive propulsion, manoeuvring, and dynamic positioning system for an Emergency Towing Vessel (ETV). The vessel is owned by Smit Lamnalco, a subsidiary of Boskalis, and will operate for the Austral Maritime Safety Authority. Its mission is to protect the marine environment around the Great Barrier Reef and Torres Strait – some of the most precious marine areas in the world. Brunvoll twin-screw propulsion system Brunvoll consists of the twin-screw propulsion system, 4 tunnel thrusters, and advanced control system The delivery from Brunvoll consists of the twin-screw propulsion system, four tunnel thrusters, and a highly advanced control system. “We are proud and humble for been chosen by such a major player in the maritime industry. The control system for this vessel is one of the most advanced systems to date by Brunvoll." "We have been working with this project for quite a while, and it is outer most rewarding when it finally comes together. All disciplines in Brunvoll have been working closely together with the owner and designer to realise this project, and even though the schedule is tight we will deliver on time,” says Oddbjørn Følsvik, VP Sales at Brunvoll. DP system features The control system delivery is one of the most advanced from Brunvoll to date. It includes Brunvoll’s Propulsion and Thruster Control system (BruCon PTC), Brunvoll’s Dynamic Positioning system (BruCon DP2), and Brunvoll’s Joystick control (BruCon JS). The DP system features Target Tracking, which allows the vessel to follow objects, such as Remotely Operated Vehicles (ROVs). Twin screw propulsion solution The propellers will have a maximum power output of 3800 kW each, and a diameter of 3.5 metres The twin screw propulsion solution consists of a pair of controllable pitch propellers with reduction gearboxes and nozzles. The propellers will have a maximum power output of 3800 kW each, and a diameter of 3.5 metres. The gearboxes also feature Power Take-Out (PTO) and Power Take-In (PTI), which allows for a broad variety of operational modes. All the different modes are available both in normal operation and while the vessel is in DP2 operation as well. Operational modes of the system The system will feature the following operational modes: PTO: Main engines and shaft generators running PTO on both sides, delivering both power for propulsion and electricity on board. PTI: Propulsion on both sides running by the electrical motors, powered either by auxiliary motors or batteries. In lower load conditions, this mode can be used to avoid starting up the larger main engine and instead run smaller engines on more optimal load conditions. Hybrid: One side runs PTO and the other runs PTI, i.e., one main engine powers both propellers. Adding further flexibility and optimal running of engines. Bollard pull: Both sides powered by main engines and PTI, for maximum bollard pull. This boost mode takes out the full power of the vessel to support special operations, like towing or anchor handling. Fire Fighting: FIFI pumps engaged with less power available for propulsion, to avoid overloading the main engine. The vessel was designed by Robert Allan Ltd. with the design annotation RASalvor 6500. The dimensions of the ETV are a length of 65 metres and a bollard pull capability of 120 tons.

Sentinel Marine, a member of the Cyan Renewables Group, has signed a shipbuilding contract with Jiangmen Hangtong Shipbuilding Co., Ltd for the construction of a 65-metre multi-role energy support vessel to join their fleet, with options for a further three vessels. The new vessel will bring the fleet number to 15. The initial vessel in this innovative new class is scheduled for delivery in Q2 2027. The newbuild will be a DP2 vessel with a deadweight of 1,600 tonnes, with 375m² of clear deck space and substantial under-deck capacity for fuel oil, potable water, recovered oil, and mono ethylene glycol (MEG). Dutch and Danish ERRV regulations Design includes an optional work-to-work gangway, an under-deck supplies storage and hybrid propulsion Designed as a Group B (A option) UK emergency response and rescue vessel (ERRV), the vessel will feature a fast rescue craft (FRC) and hybrid daughter craft. This transitional vessel will also meet design criteria for Dutch and Danish ERRV regulations and will offer accommodation for between 37 and 47 personnel. In addition to its emergency response capability, the design includes an optional work-to-work gangway, under-deck supplies warehouse and battery hybrid propulsion, ensuring suitability for a broad range of operations, including offshore wind and transitional energy support, government services, carbon capture, and maritime security. Innovation in marine operations Rory Deans, CEO of Sentinel Marine, says, "This new vessel, and the future sister ships, mark an exciting step forward in our strategic vision to deliver ‘Blue to Green' operations. The new vessel will be a cornerstone in our journey towards cleaner, multi-sector marine services that remain robust and reliable." Keng Lin Lee, CEO of Cyan Renewables, said: "Cyan is delighted to be investing in expanding our fleet with this innovative new multi-purpose support vessel enhancing Sentinel's reputation as the pioneering UK-based ERRV provider with the youngest fleet in Europe. The investment aligns with Sentinel Marine and Cyan Renewables' shared commitment to sustainable innovation in marine operations, strengthening the group's capabilities across multiple offshore sectors."

Fincantieri, a pioneer in complex shipbuilding, and Accenture, one of the world’s pioneering professional services companies, have signed an agreement to establish Fincantieri Ingenium, a new joint venture. The company will be owned 70% by Fincantieri NexTech – a subsidiary of the Fincantieri Group – and 30% by Accenture. The initiative stems from a Memorandum of Understanding signed in July 2024 and combines Fincantieri’s technological expertise in the naval sector with Accenture’s advanced digital capabilities and digital engineering and manufacturing expertise. The project is subject to customary regulatory clearances. Fincantieri Group’s Industrial Plan Fincantieri Ingenium has been created to accelerate digital transformation across the cruise industry Fincantieri Ingenium has been created to accelerate digital transformation across the cruise, defence, and port infrastructure sectors. It will play a key role in executing the strategy outlined in Fincantieri Group’s Industrial Plan. The goal is to enhance the offering of digital services and systems based on recent advances in technologies such as artificial intelligence by optimising the entire value chain through data utilisation and process transformation. Accenture’s extensive experience in digital platforms The joint venture will integrate Accenture’s extensive experience in digital platforms, AI, connectivity and IoT, cybersecurity, and service design with Fincantieri’s deep technological know-how in the naval and defense industries. This powerful combination will enable the development of new technological capabilities and skills, while also attracting and training new talent. Next-generation ships and existing fleets The first ship equipped with Navis Sapiens is expected to enter service by the end of 2025 Among the first strategic initiatives of the new company is the development of Navis Sapiens, a digital ecosystem designed for next-generation ships and the upgrade of existing fleets. The project spans three key dimensions: the creation of a portfolio of application services to optimise operational efficiency and lifecycle management for ships and onshore infrastructure; the development of a digital platform enabling these applications and advanced AI-driven functionalities, with a strong focus on cybersecurity; and a marketplace to facilitate the exchange of solutions - including those from third parties - to deliver high value-added services and enable new business models across the maritime ecosystem. The first ship equipped with Navis Sapiens is expected to enter service by the end of 2025. Ships and onshore ecosystems In synergy with Navis Sapiens, the joint venture also plans to enhance real-time data exchange and connectivity between ships and onshore ecosystems - including ports and shipyards - through a sea-to-shore interoperability solution to increase cross-functional process efficiency. This project will help improve the competitiveness of Italian ports by optimising performance across the entire maritime and land-based value chain. National maritime ecosystem The plans will be designed to reduce environmental impact via data-driven energy optimisation All initiatives will be promoted with sustainability as a core pillar. The systems will be designed to reduce environmental impact through data-driven energy optimisation, supporting shipowners in reducing fuel consumption. The initiatives already underway, as well as those to come, will generate significant value for Fincantieri, the national maritime ecosystem, and the country as a whole, with a positive impact on a global scale. Fincantieri technological innovation Pierroberto Folgiero, CEO and General Manager of Fincantieri, said: "With Fincantieri Ingenium, we strengthen our leadership position in technological innovation applied to shipbuilding and the naval engineering industry. This joint venture represents a strategic step forward in accelerating the digitalisation of the sector, leveraging artificial intelligence and the most advanced technologies." "Thanks to the synergy with Accenture, we will develop cutting-edge solutions that will make our ships and infrastructures increasingly connected, efficient and sustainable, consolidating Fincantieri's role as a pioneer in the sector." Step forward in maritime innovation Teodoro Lio, MU Lead for ICEG and CEO of Accenture Italy, commented: “We are excited about this joint venture with Fincantieri, which marks a significant step forward in maritime innovation and is a tangible example of collaboration between two organisations committed to transforming the market and creating new value." "With Fincantieri Ingenium, we are combining our respective strengths to shape new operating models that will transform maritime operations through innovative technologies.”

Technology group Wärtsilä has introduced a new methane slip reduction solution for its Wärtsilä 50DF dual-fuel engine. The new technology, which converts Wärtsilä 50DF dual-fuel (DF) engines to spark gas (SG) operation, enables a more optimised combustion process, thereby improving efficiency and lowering methane emissions. Wärtsilä 50DF engine Whilst operating on LNG, the new ‘Spark Gas Conversion for Wärtsilä 50DF’ is designed to reduce methane emissions up to 75 percent more than the standard Wärtsilä 50DF engine. The Spark Gas Conversion for Wärtsilä 50DF minimises methane emissions by introducing an electrically controlled pre-combustion chamber valve for a more optimised combustion process. Use of LNG and cutting methane emissions New solution reduces methane emissions down to 1.1 percent of fuel use The estimated result is that, on an IMO weighted (E2-cycle) average, the new solution reduces methane emissions down to 1.1 percent of fuel use. “The use of LNG and cutting methane emissions is one of the most effective ways to decrease overall greenhouse gas (GHG) emissions from marine engines over the next decade, complementing other efforts to reduce CO2 emissions,” comments Roger Holm, President of Wärtsilä Marine & Executive Vice President at Wärtsilä Corporation. “As the shipping industry strives for more sustainable operations, this new solution represents an important milestone on the road to advancing lower carbon fleets.” Chevron LNG Carriers The development of the solution, which consists of converting one-to-two of the total DF engines to SG, was made possible through extensive collaboration between Wärtsilä and Chevron Shipping Company. It was announced earlier that one engine on six Chevron LNG Carriers will be converted from DF to SG as part of Chevron’s aim to reducing the carbon intensity of its operations. Lower methane emissions The new solution is optimised for LNG as fuel, thus producing a better power work per unit of fuel The solution is now available to all vessels in the industry with existing Wärtsilä 50DF engines diesel-electric propulsion, the majority of which are LNG carriers. The new solution is optimised for LNG as fuel, therefore producing a better energy output per unit of fuel. This means fuel gas savings of up to 4.6 percent, as well as lower methane emissions. LNG-fuelled engines Holm continues: “Wärtsilä has an extensive track-record in reducing methane slip from LNG-fuelled engines, not only as newbuild solutions, but also through retrofitting existing installations. This latest technology complements our extensive portfolio of solutions aimed at reducing methane emissions from vessels.” With three decades of experience in LNG technology, Wärtsilä is providing market-pioneering performance-both with the dual fuel flexibility provided by the DF engine, as well as with the single fuel SG engine.

Hefring Marine, an Icelandic pioneer in intelligent marine technology, and Marine AI, a UK-based pioneer in autonomous vessel control systems, announced a new mutually beneficial partnership. This collaboration aims to enhance autonomous maritime operations by integrating Hefring Marine’s Intelligent Marine Assistance System (IMAS) with Marine AI’s GuardianAI autonomy suite. Hefring Marine’s IMAS Hefring Marine’s IMAS will complement GuardianAI’s existing capabilities by providing real-time insights This partnership sets the stage for seamless technological integration, where Hefring Marine’s IMAS will complement GuardianAI’s existing capabilities by providing real-time insights into sea conditions, optimising vessel operations, and improving safety. The collaboration will ensure that IMAS is fully compatible with the GuardianAI marine autonomy stack, with future plans to offer IMAS as an OEM-supported module within the GuardianAI suite. Integrating IMAS with GuardianAI “Our new venture with Marine AI is a great win for autonomous maritime technology,” said Karl Birgir Björnsson, CEO of Hefring Marine. “By integrating IMAS with GuardianAI, we are enabling vessels to operate more efficiently, safely, and with greater situational awareness. This partnership is a testament to our commitment to enhancing fleet intelligence and optimising maritime operations.” IMAS leverages AI technology Hefring Marine’s IMAS leverages AI technology, sensor data, and edge computing to insights Hefring Marine’s IMAS leverages AI technology, sensor data, and edge computing to deliver actionable insights, improving vessel efficiency, reducing fuel consumption, and enhancing onboard safety. Marine AI’s GuardianAI is a modular, state-of-the-art autonomous vessel control system capable of IMO Level 4+ autonomy, enabling high-fidelity situational awareness, tactical path routeing, and intelligent vessel control. How autonomous vessels interact with their environments “The synergy between GuardianAI and IMAS will redefine how autonomous vessels interact with their environments,” said Tom Rooney, general manager of Marine AI. “IMAS acts as the ‘human feel’ in an autonomous setting, allowing vessels to respond dynamically to real-time conditions. This partnership enables a holistic approach to autonomy, ensuring both crewed and uncrewed vessels can navigate safely and efficiently.” Focus on key maritime sectors Partnership will provide enhanced situational awareness and improved vessel in sea conditions This partnership will focus on key maritime sectors, including rescue operations, law enforcement, defense, offshore support, crew transfer and the leisure industry. By integrating IMAS within GuardianAI, the partnership will provide enhanced situational awareness and improved vessel survivability in various sea conditions. Capabilities of autonomous vessel operations Future plans include ongoing joint product development and system enhancements to expand the capabilities of autonomous vessel operations. The scalable nature of this technology means it can be applied across a broad spectrum of vessel types, from small uncrewed autonomous vessels to large passenger ships.

ClassNK has issued an approval in principle (AiP) for an Onboard Carbon Capture and Storage system (OCCS) developed by Mitsubishi Shipbuilding. The certification confirms its feasibility from regulatory and safety perspectives. Interest in CO2 capture the method from exhaust gases is growing alongside fuel conversion as part of efforts to reduce GHG emissions from ships. In response, the development of OCCS is progressing. Safety requirements for OCCS ClassNK will often strive to contribute to advanced decarbonisation initiatives via safety assessments To support the smooth development and introduction of related technologies, ClassNK has published the 'Guidelines for Shipboard CO2 Capture and Storage Systems' as a subset of the ClassNK Transition Support Services. This guideline outlines safety requirements for OCCS and its installation on ships. ClassNK reviewed the design of the system based on 'Guidelines for Shipboard CO2 Capture and Storage Systems'. Upon confirming compliance with the prescribed requirements, ClassNK issues an AiP. ClassNK will continually strive to contribute to advanced decarbonisation initiatives through safety assessments and more. Approval in Principle (AiP) At the initial stage of designing or before the specific target ship to be implemented is decided, the design is examined based on the existing regulations such as international conventions and ship classification rules, and an Approval in Principle (AiP) is issued as proof of conformity with requirements. It also prevents rework of regulatory aspects in the post-process, shortens the examination time at the time of class registration, and can be used as a technical basis for external appeal of the design status.

Brunvoll has signed a contract with Rizhao Gangda Shipyard for the delivery of an extensive propulsion, manoeuvring, and dynamic positioning system for an Emergency Towing Vessel (ETV). The vessel is owned by Smit Lamnalco, a subsidiary of Boskalis, and will operate for the Austral Maritime Safety Authority. Its mission is to protect the marine environment around the Great Barrier Reef and Torres Strait – some of the most precious marine areas in the world. Brunvoll twin-screw propulsion system Brunvoll consists of the twin-screw propulsion system, 4 tunnel thrusters, and advanced control system The delivery from Brunvoll consists of the twin-screw propulsion system, four tunnel thrusters, and a highly advanced control system. “We are proud and humble for been chosen by such a major player in the maritime industry. The control system for this vessel is one of the most advanced systems to date by Brunvoll." "We have been working with this project for quite a while, and it is outer most rewarding when it finally comes together. All disciplines in Brunvoll have been working closely together with the owner and designer to realise this project, and even though the schedule is tight we will deliver on time,” says Oddbjørn Følsvik, VP Sales at Brunvoll. DP system features The control system delivery is one of the most advanced from Brunvoll to date. It includes Brunvoll’s Propulsion and Thruster Control system (BruCon PTC), Brunvoll’s Dynamic Positioning system (BruCon DP2), and Brunvoll’s Joystick control (BruCon JS). The DP system features Target Tracking, which allows the vessel to follow objects, such as Remotely Operated Vehicles (ROVs). Twin screw propulsion solution The propellers will have a maximum power output of 3800 kW each, and a diameter of 3.5 metres The twin screw propulsion solution consists of a pair of controllable pitch propellers with reduction gearboxes and nozzles. The propellers will have a maximum power output of 3800 kW each, and a diameter of 3.5 metres. The gearboxes also feature Power Take-Out (PTO) and Power Take-In (PTI), which allows for a broad variety of operational modes. All the different modes are available both in normal operation and while the vessel is in DP2 operation as well. Operational modes of the system The system will feature the following operational modes: PTO: Main engines and shaft generators running PTO on both sides, delivering both power for propulsion and electricity on board. PTI: Propulsion on both sides running by the electrical motors, powered either by auxiliary motors or batteries. In lower load conditions, this mode can be used to avoid starting up the larger main engine and instead run smaller engines on more optimal load conditions. Hybrid: One side runs PTO and the other runs PTI, i.e., one main engine powers both propellers. Adding further flexibility and optimal running of engines. Bollard pull: Both sides powered by main engines and PTI, for maximum bollard pull. This boost mode takes out the full power of the vessel to support special operations, like towing or anchor handling. Fire Fighting: FIFI pumps engaged with less power available for propulsion, to avoid overloading the main engine. The vessel was designed by Robert Allan Ltd. with the design annotation RASalvor 6500. The dimensions of the ETV are a length of 65 metres and a bollard pull capability of 120 tons.

Sentinel Marine, a member of the Cyan Renewables Group, has signed a shipbuilding contract with Jiangmen Hangtong Shipbuilding Co., Ltd for the construction of a 65-metre multi-role energy support vessel to join their fleet, with options for a further three vessels. The new vessel will bring the fleet number to 15. The initial vessel in this innovative new class is scheduled for delivery in Q2 2027. The newbuild will be a DP2 vessel with a deadweight of 1,600 tonnes, with 375m² of clear deck space and substantial under-deck capacity for fuel oil, potable water, recovered oil, and mono ethylene glycol (MEG). Dutch and Danish ERRV regulations Design includes an optional work-to-work gangway, an under-deck supplies storage and hybrid propulsion Designed as a Group B (A option) UK emergency response and rescue vessel (ERRV), the vessel will feature a fast rescue craft (FRC) and hybrid daughter craft. This transitional vessel will also meet design criteria for Dutch and Danish ERRV regulations and will offer accommodation for between 37 and 47 personnel. In addition to its emergency response capability, the design includes an optional work-to-work gangway, under-deck supplies warehouse and battery hybrid propulsion, ensuring suitability for a broad range of operations, including offshore wind and transitional energy support, government services, carbon capture, and maritime security. Innovation in marine operations Rory Deans, CEO of Sentinel Marine, says, "This new vessel, and the future sister ships, mark an exciting step forward in our strategic vision to deliver ‘Blue to Green' operations. The new vessel will be a cornerstone in our journey towards cleaner, multi-sector marine services that remain robust and reliable." Keng Lin Lee, CEO of Cyan Renewables, said: "Cyan is delighted to be investing in expanding our fleet with this innovative new multi-purpose support vessel enhancing Sentinel's reputation as the pioneering UK-based ERRV provider with the youngest fleet in Europe. The investment aligns with Sentinel Marine and Cyan Renewables' shared commitment to sustainable innovation in marine operations, strengthening the group's capabilities across multiple offshore sectors."

Expert commentary

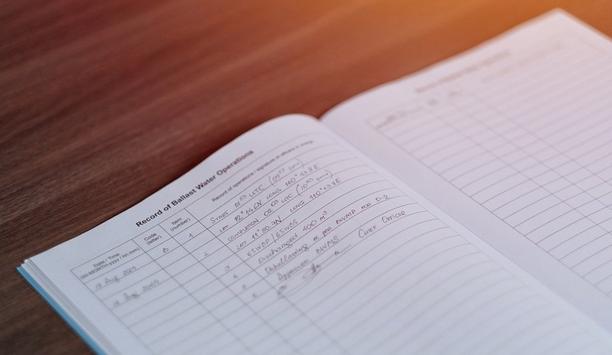

When the Ballast Water Management (BWM) Convention came into force in 2004, it was in response to a crisis we couldn’t afford to ignore—one where invasive aquatic species, carried silently in ships’ ballast tanks, were devastating marine ecosystems. Now, two decades later, compliance with this environmental safeguard is no longer optional—and yet, as recent industry findings reveal, record-keeping failures account for 58% of compliance issues. That’s not a technology problem. That’s a documentation problem —one rooted deeply in data management practices and crew training, where small oversights lead to documentation issues, that may cascade into costly compliance failures. And that’s precisely where digital systems excel, guiding crews clearly to avoid mistakes in the first place. New ballast regulations At the IMO’s 82nd Marine Environment Protection Committee (MEPC 82), new ballast water record-keeping regulations were approved, coming into effect from 1 February 2025. These updates mark a significant tightening of documentation standards—and they could catch unprepared shipowners off guard if not acted on promptly. Why ballast water record-keeping is back in the spotlight These new updates aim to change that—and they’re stricter, smarter, and more detailed than before While MEPC 82 made headlines for advancing decarbonisation policies and ECAs in the Arctic and Norwegian Sea, it also honed in on ballast water—a topic that has quietly regained importance. The committee approved critical updates to how ballast water operations and ballast water management system (BWMS) maintenance are recorded. The goal: Enhance transparency, reduce ambiguity, and reinforce environmental protection by making records more structured, traceable, and actionable. This renewed focus is both a warning and an opportunity. In recent years, too many Port State Control detentions and inspection delays have stemmed not from hardware failures, but from poorly maintained or unclear ballast water records. These new updates aim to change that—and they’re stricter, smarter, and more detailed than before. What’s changing: Bypass scenarios and maintenance logging The revised guidelines introduce two new scenarios for vessels dealing with challenging water quality (CWQ) in ports: Scenario 3: A reactive bypass of the BWMS due to unforeseen poor water quality. Scenario 4: A pre-emptive bypass based on anticipated CWQ conditions. These additions are essential for vessels operating globally, particularly those above 400GT. They ensure that alternative operations—like ballast water exchange plus treatment (BWE + BWT)—are clearly documented. Without accurate records, even legitimate actions can fall short of compliance. Ballast Water Management Plan and OEM manuals MEPC 82 also mandates that BWMS care procedures must now be recorded directly in BWRB MEPC 82 also mandates that BWMS maintenance procedures must now be recorded directly in the Ballast Water Record Book (BWRB), in line with the ship’s Ballast Water Management Plan and Original Equipment Manufacturer (OEM) manuals. Responsible crew members must sign off on these records, ensuring traceability and crew accountability. This step isn’t just regulatory housekeeping—it aligns ballast water maintenance with how other onboard systems are already tracked, from engines to emissions. It’s a logical, overdue move toward consistency across compliance. Paper or digital: The format dilemma While the BWRB can still be maintained on paper or electronically, the burden of new structured data fields and stricter reporting timelines will be felt most by those still tied to manual systems. Each additional layer of documentation increases the chance of human error—and with nearly 6 in 10 compliance failures already stemming from admin issues, that’s a risk many operators can’t afford. This is where digital solutions can offer real relief. At NAPA, we’ve already implemented the latest IMO guidelines into our electronic logbook, so crews can comply with MEPC.369(80) requirements out of the box. With ready-made entry templates and smart input validation, data entry is quick, accurate, and audit-ready. NAPA implemented the latest IMO guidelines into an electronic logbook. Better still, once updated, operators can apply for the BWM Convention Electronic Record Book Declaration from their flag—ensuring that compliance is recognised internationally under MEPC.372(80). Less admin, more assurance Electronic logbooks don’t just streamline compliance—they enable better decision-making. When connected to onboard systems, they automatically pull operational data into the BWRB, reducing manual work and error margins. This frees up the crew to focus on operations and safety, rather than paperwork. From a management perspective, real-time visibility into ballast operations and maintenance records helps shore teams stay ahead of inspections and identify potential compliance gaps early. One logbook, many regulations While ballast water is the focus today, it’s not the only regulation demanding attention While ballast water is the focus today, it’s not the only regulation demanding attention. At NAPA, we’ve designed our logbook to support a wide range of evolving compliance frameworks—including MARPOL, EU-ETS, EU-MRV, CII, and the Garbage Record Book. This unified approach removes silos, reduces duplicated effort, and gives operators a more holistic view of vessel performance and compliance. A smarter way forward With decarbonisation and environmental regulations shifting at breakneck pace, even the most experienced crews and fleet managers can struggle to stay up to date. That’s where technology has a crucial role to play—not to replace expertise, but to support it. At NAPA, we work closely with shipowners and operators to configure regulatory record book templates according to their fleet workflows and each vessel’s specific operational profile. This ensures accuracy, ease of use, and most importantly, continuous compliance—even as the rules keep changing. Because in today’s compliance landscape, staying ahead isn’t just about meeting the minimum. It’s about building systems that help you adapt, respond, and thrive. And that starts with getting the record-keeping and data management right.

President Donald Trump has already made plenty of headlines since taking up his second term in the White House, including with the announcement of numerous new tariffs on imports. The 47th United States President issued three executive orders on February 1st 2025, just days after his inauguration, which directed the US to impose an additional 25 percent ad valorem rate of duty on imports from Canada and Mexico, as well as ten percent on imports from China. How Trump’s 2nd term as US President Cleveland Containers has analysed the early reactions to these announcements Excluding Canadian energy resources exports – which instead will be hit with a ten percent tariff – the tariffs have been applied to all imports which are either entered for consumption or withdrawn from warehouse for consumption on or after 12:01 am Eastern Standard Time on February 4th 2025. President Trump also told reporters on February 8th 2025 that a 25 percent tariff on all American steel and aluminium imports was coming into effect across the US during February. Leading 40ft shipping container supplier Cleveland Containers has analysed the early reactions to these announcements and how President Trump’s second term as US President could affect the world’s shipping industry, especially when looking back at his first term. Reaction to President Trump’s tariff announcements Mexico, Canada and China were all quick to react to President Trump’s announcement of tariffs on imports. Mexican President Claudia Sheinbaum said her country would vow for resilience against the measures, while a senior government official in Canada said that their country would challenge the decision by taking legal action through the necessary international bodies. China has also said it would be challenging the tariffs at the World Trade Organisation. According to the country’s finance ministry, as reported on by Geopolitical Intelligence Services, Beijing were moving to place levies of 15 percent on American coal and liquefied natural gas, as well as levies of ten percent on crude oil, certain vehicles and farm equipment. Beginning of making America rich again When it comes to the announcement of the tariff on all American steel and aluminium imports, President Trump told reporters in the Oval Office: "This is a big deal, the beginning of making America rich again. Our nation requires steel and aluminium to be made in America, not in foreign lands.” Francois-Phillippe Champagne, the Minister of Innovation in Canada, stated that the tariffs were "totally unjustified" though, before adding in a post on X: "Canadian steel and aluminium support key industries in the US, from defence, shipbuilding and auto. We will continue to stand up for Canada, our workers, and our industries." How might President Trump’s 2nd term affect shipping sector? Bruce Chan, an analyst in the Transportation and Future Mobility sectors at wealth management and investment banking Just ahead of President Trump taking office for the second time, J. Bruce Chan, an analyst in the Transportation and Future Mobility sectors at wealth management and investment banking firm Stifel, believed that the shipping industry was prepared for the new tariffs. However, he also stated to the Morning Star: "President Trump's Administration promises to usher in a new trade and tariff regime. As such, it's difficult to assess the ultimate impact to the freight transportation industry. Prima facie, we believe tariffs are a drag on freight demand, effectively resulting in higher costs for shippers that are generally passed on to end consumers over time." Attention to the American sanction announcements Mr. Chan went on to note that those involved in shipping containers across continents should be paying particular attention to the American sanction announcements. He commented: "Because almost all trans-Pacific trade moves over the ocean, we believe ocean container shipping will see the largest direct impact. But for shippers and retailers, there is no cheaper way to move goods than over the ocean, so there are few modal alternatives if production remains in Asia. We see the most risk for maritime shipping, with containers and dry bulk being more acute, with more insulation for oil and gas tankers." Shipping news and intelligence service Various sources have looked back on President Trump’s first term to get an idea of what could be expected As President Trump has just become his second term as US president and the American sanctions have only just been announced, it will take time to see what the true impact will be. However, various sources have looked back on President Trump’s first term to get an idea of what could be expected. For example, shipping news and intelligence service Lloyd’s List pointed out that tariffs introduced when President Trump was last in the White House had a noticeable effect on both spot container freight rates and import timing. Cargoes were pulled forward in the second half of 2018 by importers as they looked to beat tariff deadlines, which resulted in higher spot rates temporarily before affecting rates in 2019 because of inventory overhang. Could repeat results be seen across 2025 and 2026? Long-life inputs and goods from the tariff countries Jason Miller, a freight economist and professor of supply chain management at Michigan State University, certainly seemed to think so. Speaking to Lloyd’s List before President Trump’s 2024 presidential victory when the tariffs were only part of campaign proposals at that point, he said: “We will see front-loading like we have never seen before in 2025. There would be a massive pull-forward of demand as everybody rushes to bring in long-life inputs and goods from tariff countries, especially China.” Shipping demand and routes Shipping demand and routes could be affected due to trade uncertainty too Meanwhile, international shipping and forwarding agents Supreme Freight Services reported that increased tariffs may cause disruption to shipping volumes and global supply chains, if trade policies introduced by President Trump during his first term are anything to go by. Shipping demand and routes could be affected due to trade uncertainty too, though the publication also acknowledged that increased investment in ports and inland waterways across the US could improve efficiency for domestic and international trade alike. New American sanctions Cleveland Containers has looked to reassure its customers that any disruption caused by the new American sanctions will be minimised at the firm. Hayley Hedley, the company’s Commercial Director, stated: “Recent history certainly suggests that the new tariffs being introduced by President Trump will have various knock-on effects across the shipping industry." “Fortunately, Cleveland Containers has a continuous supply of shipping containers entering the UK. We work with several agents to ship from various locations, as well as having good stock on the ground, so are confident in our ability to provide for our customers.”

Demand for ammonia is being transformed by the energy transition. Until recently used as an input for fertiliser and chemical products, new markets for green and blue ammonia are emerging, replacing fossil energy in power generation, steel production and marine fuel. Today some 200m tonnes per annum of ammonia is produced worldwide with 20m tpa transported in LPG carriers. The scale of the emerging and potential demand will see these figures rise; how quickly this can be achieved will determine its take-up as a shipping fuel. New or evolving technology The interest in ammonia stems both from its ‘zero emissions’ when used as fuel and because its production isn’t dependent on biogenic carbon sources. As the global economy transitions away from fossil-based fuels, biogenic carbon – from captured CO2, electrolysis and even waste sources – will be subject to increasing competition from other consumers. Shipyards around the world are considering the advantages that operating on ammonia may provide Accordingly, owners, operators, designers, and shipyards around the world are considering the advantages that operating on ammonia may provide. However, when considering any new or evolving technology, it is important to have a clear understanding of not only the benefits, but the challenges that may be involved. Challenges of ammonia bunkering Biogenic carbon will increasingly replace fossil-based carbon in many of the products in use today in industry and consumer goods. Competition from the energy and aviation sectors will inevitably lead to increased prices but production capacity will need to come from industrial sources rather than biomass harvested for this purpose. ABS has produced a Technical and Operational Advisory on Ammonia Bunkering in response to the need for better understanding by members of the maritime industry. It is intended to provide guidance on the technical and operational challenges of ammonia bunkering, both from the bunker vessel’s perspective (or land-side source) and from the receiving vessel’s perspective. Managing emissions Particular attention needs to be paid to the potential presence of ammonia slip, N2O or NOx emissions The carbon emissions from the combustion of ammonia are associated with and dependent on the type and amount of pilot fuel used. The use of biofuel as pilot fuel may further reduce the emissions. In addition, the emissions of sulphur dioxide, heavy metals, hydrocarbons, and polycyclic aromatic hydrocarbons (PAHs) drop to zero (or near zero, depending on the pilot fuel used); and particulate matters (PM) are also substantially reduced compared to conventional fossil fuels. However, particular attention needs to be paid to the potential presence of ammonia slip, N2O or NOx emissions, due to the imperfect combustion of ammonia and the use of pilot fuels. These emissions will need to be kept as low as possible by further adjustment and development of the engine technology or using an on-board exhaust gas treatment technology. Currently, hydrogen for ammonia production is typically produced by means of steam methane reforming (SMR) or autothermal reforming (ATR) of natural gas (grey ammonia). If the CO2 emissions from the process of converting natural gas are captured and stored, the ammonia is typically referred to as ‘blue’. Production of blue ammonia Moreover, the production of blue ammonia retains a dependency on fossil fuels. Therefore, ‘green ammonia’, which is produced from hydrogen made from renewable energy sources (green hydrogen), is generally considered to be the end-solution for decarbonisation which leads to a sustainable fuel cycle, while blue ammonia is seen to have an intermediate role. The potential well-to-wake GHG emissions of green ammonia are estimated to be around 91% lower than for grey ammonia, and 85% lower than HFO and MGO. The grey ammonia production network is already well established and global, ensuring easier accessibility across major ports worldwide. Infrastructure and regulation Specific requirements for ammonia bunkering are under discussion by all marine stakeholders This will help green ammonia become readily available for bunkering and distribution once sufficient production and infrastructure are in place. On the other hand, when compared with liquid hydrogen or LNG which can be stored at temperatures of −253°C and −162°C, respectively, liquid ammonia can be stored and transported at −33°C near atmospheric pressure, which allows for easier adaptation of existing fuel infrastructure on ships and at ports. While specific requirements for ammonia bunkering are under discussion by all marine stakeholders, the requirements for shipping ammonia as cargo, including loading and unloading operations, have been established in the marine industry and are covered by the IMO International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) and incorporated in the ABS Rules for Building and Classing Marine Vessels Part 5C Chapter 8 “Vessels Intended to Carry Liquefied Gases in Bulk”. For the use of ammonia as bunker fuel, all segments of the marine industry (including IMO, Class Societies, Port Authorities, and industry agencies) are working to develop requirements and procedures specific to ammonia bunkering operations. Refer to the section “Regulatory Organisation” of this Advisory for the current activities of each marine industry segment. Bunkering Options Ship-to-ship bunkering is the most popular mode for transferring fuel to ocean-going vessels There are three main methods of bunkering ammonia to ships. Truck-to-ship is the process of transferring ammonia from trucks or truck trailers to a receiving vessel using ammonia as fuel. Typically, the tanks on the truck are pressurised and store ammonia at ambient temperature. To increase bunker capacity and transfer rates, a manifold may be used to connect several trucks simultaneously to supply the receiving vessel. Truck-to-ship transfer operations may provide greater operational flexibility, but at the same time could induce operational restrictions and limitations by the local Authority. Ship-to-ship bunkering is the most popular mode for transferring fuel to ocean-going vessels, such as container ships, tankers, and bulk carriers, which require large fuel capacities and greater quantities of fuel to be bunkered. Terminal-to-ship bunkering transfers ammonia from an ammonia storage terminal pipeline connected to receiving vessels via a hose assembly or loading arm. Ammonia Safety Ammonia is toxic and reacts violently and explosively with oxidising gases such as chlorine, bromine, acids, and other halogens. When ammonia is inhaled, swallowed or absorbed via skin contact, it reacts with water in the body, producing ammonium hydroxide. Due to these toxicity issues, ammonia is classified as a hazardous substance, with the level and time of exposure being controlled by several national standards. The level of competency needed for each task depends on the role and duties of the individual A combination of both training and operational experience is key to developing the required competencies for ammonia bunkering operations. The level of competency needed for each task depends on the role and responsibilities of the individual. Therefore, the training may vary from person to person. Seafarers on board ships using ammonia fuel should have completed training to attain the abilities that are appropriate to the capacity to be filled, and duties and responsibilities to be taken up. The master, officers, ratings and other personnel on ships using ammonia fuel should be trained and qualified in accordance with regulation V/3 of the STCW Convention and section A-V/3 of the STCW Code, taking into account the specific hazards of ammonia used as fuel. Ship-specific training Ship-specific training is to be reviewed and approved by governing regulatory authorities. The IGF Code provides detailed training requirements for ships that use gases or other low-flashpoint fuels. Ships under the jurisdiction of flag administrations signatory to SOLAS should ensure that seafarers should have the specified certificates of proficiency and the administration shall approve courses and issue endorsements indicating completion of the qualification. All crew must be provided with and be made aware of the emergency procedures and must be trained in any roles and responsibilities they may have. Training, drills and exercises to prepare crews for emergencies are to be provided. Lessons learned from past operations should be incorporated to improve emergency procedures. Procedures should cover all scenarios specific to the ship, type of incident, equipment, and associated areas.

Harbour insights

Ammonia is gaining traction as a future fuel in the maritime industry, primarily due to its potential to significantly reduce greenhouse gas emissions. A key driver for ammonia's interest is that it can be carbon-free when combusted, which aligns with the maritime industry's increasing pressure to meet emissions regulations. However, most ammonia production currently relies on fossil fuels. Transitioning to "green ammonia" production is crucial for sustainability. If "green ammonia" is produced using renewable energy sources, it offers a pathway to near-zero emissions shipping. Safety measures and regulations Ammonia’s volumetric energy density – higher than hydrogen – makes it more practical for onboard storage. However, ammonia is toxic, which requires stringent safety measures and regulations for handling and storage. The combustion of ammonia can produce nitrous oxide (N2O), a potent greenhouse gas. Therefore, mitigation technologies are needed. Building the necessary infrastructure for ammonia bunkering and supply will be a significant undertaking. Developing guidelines for safe use Ammonia is poised to play a significant role in the maritime industry's transition to a future The International Maritime Organization (IMO) is developing guidelines for the safe use of ammonia as a marine fuel. Increasing numbers of companies are investing in the development of ammonia-fueled vessels and technologies. European Union (EU) legislation, such as the EU Emissions Trading System (ETS) and the FuelEU initiative to support decarbonisation, are pushing the maritime industry towards the use of alternative fuels, which is increasing the potential of ammonia. While challenges remain, ammonia is poised to play a significant role in the maritime industry's transition to a more sustainable future. Ongoing research and development Ongoing research and development are focused on improving safety, reducing emissions, and scaling up production. In essence, ammonia offers a promising pathway for the maritime industry to reduce its carbon footprint, but its widespread adoption depends on overcoming technical and logistical challenges. Working toward the future of ammonia Progress is already happening as the maritime industry works toward a future that includes the use of ammonia as a fuel. For example, one project underway aims to be a pioneer in establishing a comprehensive and competitive supply chain to provide clean ammonia ship-to-ship bunkering in the U.S. West Coast. Progress is already occurring as the maritime industry works toward a future A feasibility study is being conducted at the Port of Oakland, Benicia, and nearby major ports on the U.S. West Coast. A Memorandum of Understanding (MOU) between American Bureau of Shipping, CALAMCO, Fleet Management Limited, Sumitomo Corp. and TOTE Services LLC is jointly conducting the feasibility study. "We are proud to share our industry-pioneering expertise in ammonia as a marine fuel to support this study on the U.S. West Coast,” said Panos Koutsourakis, Vice President of Global Sustainability at the American Bureau of Shipping. “Our expertise in developing safety guidelines will support the consortium to address the ammonia-specific set of safety and technology challenges.” More global ammonia developments In another development, three LPG/ammonia carrier ships have been ordered at the South Korean shipyard HD Hyundai Heavy Industries (HD HHI). Danish investment fund European Maritime Finance (EMF) and international shipping company Atlas Maritime have confirmed the order. HD HHI’s parent company, HD Korea Shipbuilding & Offshore Engineering (HD KSOE), revealed the order for $372 million in March 2024. The three 88,000 cubic-metre LPG dual-fuel carriers, capable of carrying and running on ammonia, are scheduled for delivery in December 2027. The vessels will be named EMF Viking I, II, and III. Also, Lloyd’s Register (LR) and Guangzhou Shipyard International have signed a joint development project to design the world’s largest very large ammonia carrier (VLAC). The design of the 100,000-cubic-metre vessel has been assessed in line with LR’s Structural Design Assessment and prescriptive analysis. The gas carrier will have an independent IMO Type B tank for safe carriage of the chemical. Zero-emissions operations The cargo ship, which will be 7,800 dwt, is designed to transport timber from Norway to Europe “As major economies look to co-fire ammonia in their coal power stations to reduce the CO2 footprint of their national energy mix, shipping will play a key role in distributing clean hydrogen-based commodities such as ammonia, thereby supporting nations to meet their Paris Agreement commitments," says LR's Chief Executive Nick Brown. Furthermore, a partnership of companies from Norway has ordered a pioneering short-sea cargo ship that will advance the industry’s ability to provide zero-emissions operations. The cargo ship, which will be 7,800 dwt, is designed to transport timber from Norway to Europe and will be the first to operate on ammonia and electricity. Amogy’s ammonia-to-electrical power system A start-up company focusing on ammonia-to-power technology, Amogy, demonstrated the first tugboat powered by its cracking technology just short of the fourth anniversary of the company’s launch. The trip of a 67-year-old tug along a tributary of New York State’s Hudson River is part of the company’s works to develop and commercialise its technology to decarbonise the most difficult industries. Amogy’s ammonia-to-electrical power system splits, or “cracks,” liquid ammonia into its base elements of hydrogen and nitrogen. The hydrogen is then funnelled into a fuel cell, generating the power for the vessel. Research points to the risks of ammonia The chemical, made of hydrogen and nitrogen, can also be burned as a zero-carbon fuel Today and in the future, ammonia, a main component of many fertilisers, can play a key role in a carbon-free fuel system as a convenient way to transport and store clean hydrogen. The chemical, made of hydrogen and nitrogen, can also be burned as a zero-carbon fuel. However, new research led by Princeton University scientists illustrates that even though it may not be a source of carbon pollution, ammonia's widespread use in the energy sector could pose a grave risk to the nitrogen cycle and climate without proper engineering precautions. Use of ammonia U.S. National Science Foundation (NSF)-supported research found that a mismanaged ammonia economy could ramp up emissions of nitrous oxide, a long-lived greenhouse gas around 300 times more potent than carbon dioxide and a major contributor to the thinning of the stratospheric ozone layer. The use of ammonia could lead to substantial emissions of nitrogen oxides, a class of pollutants that contribute to the formation of smog and acid rain. And it could directly leak fugitive ammonia emissions into the environment, forming air pollutants, impacting water quality and stressing ecosystems by disturbing the global nitrogen cycle. Negative impacts of an ammonia economy The researchers found that the potential negative impacts of an ammonia economy "We have great hope that ingenuity and engineering can help reduce our use of carbon-based energy sources," said Richard Yuretich, a program director in NSF's Division of Earth Sciences. "But caution is advised because of unintended environmental spillover effects that may result from new technology." The researchers found that the potential negative impacts of an ammonia economy may be minimised with proactive engineering practices, but the possibility of risks should not be taken lightly. Addressing an inconvenient reality As interest in hydrogen as a zero-carbon fuel has grown, so too has an inconvenient reality: It is notoriously difficult to store and transport over long distances, requiring storage at either temperatures below -253 degrees Celsius or at pressures as high as 700 times atmospheric pressure. Ammonia, on the other hand, is much easier to liquify, transport and store, and capable of being moved around similarly to tanks of propane. Nonetheless, the cycle of nitrogen is delicately balanced in Earth's critical zone, and extensive research must be undertaken to investigate the repercussions of ammonia combustion and to develop new methods to minimise the risks. Challenges of ammonia as a maritime fuel Here's a breakdown of the key challenges of using ammonia for maritime fuel: Toxicity and Safety: For human health, ammonia is highly toxic, posing a serious risk to human health through inhalation or skin contact. This necessitates stringent safety protocols, advanced leak detection systems, and thorough crew training. Relating to the environment, leaks can also harm aquatic ecosystems, requiring robust containment and mitigation measures. Combustion Challenges: Ammonia's combustion characteristics are less favourable than traditional fuels, requiring modifications to engine design and potentially the use of pilot fuels. Emissions: Combustion can produce nitrogen oxides (NOx) and nitrous oxide (N2O), both of which are harmful pollutants. Mitigating these emissions is crucial. "Ammonia slip" is also a concern, in which unburnt ammonia is released. Infrastructure and Supply Chain: Establishing a global network of ammonia bunkering infrastructure is a massive undertaking, requiring significant investment and coordination. Scaling up "green ammonia" production, using renewable energy, is essential for its sustainability. This requires a robust and reliable supply chain. Storage: Ammonia has specific storage requirements, and onboard storage systems must be designed for safety and efficiency. International Standards Needed: Consistent and comprehensive international regulations and standards are needed for the safe handling, transportation, and use of ammonia as a marine fuel. While the IMO is developing Guidelines, complete and ratified rules are still needed. Economic challenges: "Green ammonia" is currently more expensive than traditional fuels, although costs are expected to decrease as production scales up. Significant investments are needed in research, development, and infrastructure to make ammonia a viable maritime fuel. Also, dedicated ammonia-fueled engines are still under heavy development, and do not have widespread availability. The path to commercialisation Overcoming the variety of technical and other obstacles will require collaboration among governments, industry stakeholders, and research institutions. The timeline for ammonia deployment in maritime applications is actively unfolding, with key milestones happening now and soon. 2025 marks the first trials of two-stroke, ammonia dual-fuel engines on oceangoing ships. Engine manufacturers like MAN Energy Solutions and WinGD are progressing with their engine development, with initial deliveries soon. These pilot projects are crucial for gathering real-world data and building confidence in ammonia as a marine fuel. Development of comprehensive regulations As the maritime industry faces, ammonia is hoped to play a growing role in the fuel mix Gradual commercialisation will follow in the late-2020s as the technology matures and the infrastructure develops. The focus will be on refining engine technology, improving safety protocols, and establishing bunkering facilities in key ports. Wider adoption will likely follow in the 2030s, depending on factors such as the cost of green ammonia, the development of comprehensive regulations, and the expansion of the global supply chain. As the maritime industry faces increasing pressure to decarbonise, ammonia is expected to play a growing role in the fuel mix. Future of maritime It's likely that a combination of ammonia and other alternative fuels and technologies will be used in the future of maritime. Alternatives include methanol, liquid natural gas (LNG), hydrogen, biofuels, electric propulsion, and even nuclear power. Ammonia is a strong contender, bit it faces stiff competition from other promising technologies. The maritime industry's transition to a sustainable future will likely involve a diverse mix of fuel solutions.