MAN Energy Solutions - Experts & Thought Leaders

Latest MAN Energy Solutions news & announcements

MAN Energy Solutions has reported that its ME-LGIA (-Liquid Gas Injection Ammonia) engine, currently undergoing testing at its Research Centre Copenhagen (RCC) facility, has run at 100% engine load for the first time. Maritime energy transition Ole Pyndt Hansen, Head of Two-Stroke Research & Development, MAN Energy Solutions, said, “We began full-scale testing in November 2024 and have since proceeded in a cautious and safety-first way. We have now operated the engine on ammonia from 25–100% load, marking yet another important step forward in the maritime energy transition." "As such, we have now validated the ammonia fuel injection system over the full load curve with diesel-pilot amounts recorded according to our targets. Furthermore, the positive emission and performance characteristics from previous, single-cylinder tests have now also been validated in full-scale engine operation.” Selective Catalytic Reduction It also says that the next phase of testing will focus on performance and emission optimisation MAN Energy Solutions states that its proprietary SCR (Selective Catalytic Reduction) was operational at all test loads to treat exhaust gases and that all supply and safety systems worked as intended. It also says that the next phase of testing will focus on performance and emission optimisation, including injection and SCR systems as well as control strategies. ME-LGIA concept Christian Ludwig, Head of Global Sales & Promotion, Two-Stroke Business, MAN Energy Solutions, highlighted the ME-LGIA’s PTO (Power Take-Off) capability and said, “The ME-LGIA concept is based on the Diesel-cycle combustion principle, which makes it eminently suitable for PTO." "Before this round of testing, we simulated PTO on the ammonia engine with very positive results and are very happy to see this replicated in real life. We intend to support PTO on the ME-LGIA to the same degree as with the other Diesel-cycle engines in our low-speed portfolio.”

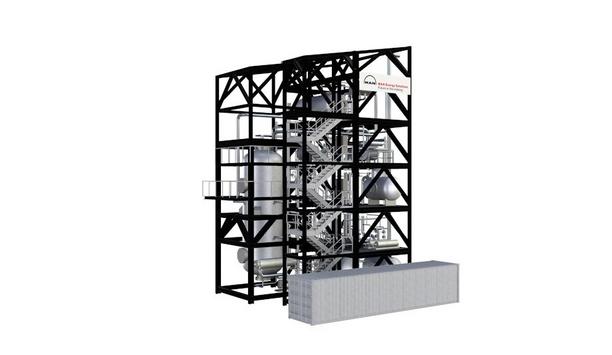

MAN Energy Solutions will deliver a 50 MWel methanation reactor for the Ren-Gas Tampere e-methane plant. The equipment delivery will consist of a catalytic methanation reactor designed and manufactured at MAN Energy Solutions Deggendorf, Germany. Ren-Gas, the pioneering green hydrogen and e-methane project developer in Finland, has announced the selection of MAN Energy Solution as one of the key technology providers for the Tampere Power-to-Gas project. MAN’s advanced technology MAN’s catalytic methanation technology will be used to convert green hydrogen into renewable e-methane MAN’s catalytic methanation technology will be used to convert green hydrogen and captured biogenic CO2 into renewable e-methane. MAN Energy Solutions will oversee the design, manufacturing, pre-fabrication, testing, delivery, installation supervision, commissioning, and performance testing of the equipment. This extensive scope guarantees that the project leverages MAN’s advanced technology and expertise at every phase, from initial design to final performance validation. European hydrogen sector Mikko Piekkala, Commercial Manager, Ren-Gas, said: "We are very excited to work with MAN Energy Solutions on our Tampere project. With their methanation technology, we are able to reach very good methane production efficiency, and to expand our sector integration opportunities even further." Mikko Piekkala adds, "Once again, it is great to work with a pioneering European partner like MAN Energy Solutions, and to advance the European hydrogen sector together." Impressive Power-to-Gas project Christian Obermeier, Sales Manager at MAN Energy Solutions Deggendorf, said: "I’m proud that Ren-Gas will rely on our proven methanation technology for this impressive Power-to-Gas project. MAN Energy Solutions is a Power-to-Gas pioneer commissioning its first methanation reactor already in 2013." Christian Obermeier adds, "Since then we have collected comprehensive and valuable operational experiences, which will be incorporated into the design of this new reactor making it highly efficient and resulting in a high methane quality. Our innovative engineering know-how paired with a decade-long experience in methanation makes us unique in the Power-to-Gas field." MAN’s methanation reactor Ren-Gas’s facility in Tampere is set to produce renewable e-methane for heavy road and maritime sector Ren-Gas’s facility in Tampere is set to produce renewable e-methane for heavy road and maritime transport sectors. In the e-methane production MAN’s methanation reactor will use, approximately 40,000 tons of carbon dioxide captured annually from the Tarastenjärvi waste incineration plant’s flue gases, along with green hydrogen produced with electrolysers. The plant will yield approximately 200 GWh of renewable fuel for heavy road and maritime transport annually, as well as 180 GWh of carbon dioxide-free district heating for Tampere’s district heating system. Green hydrogen and e-methane project Ren-Gas is the pioneering green hydrogen and e-methane project developer in Finland, which has secured significant public support for its portfolio from the Finnish Government, as well as from the EU. The company has developed an industry benchmark project portfolio, from which the Tampere facility is proceeding the construction in 2025, and commercial operation will start in 2027.

MAN Energy Solutions has announced the successful retrofit of the main engine of the ‘Maersk Halifax’ to a dual-fuel MAN B&W ME-LGIM unit. MAN PrimeServ, MAN Energy Solutions’ after-sales division, carried out the work, the first such project globally involving a VLCV (Very Large Container Vessel). The 15,000 teu vessel entered service in 2017 and was originally powered by an MAN B&W 8G95ME-C9.5 prime mover. The retrofit to an 8G95ME-LGIM Mk10.5 engine enables the Maersk Halifax to operate on green methanol, making it possible to reduce its CO2 emissions by 90%. Vessel’s engine-control system The retrofit also included an upgrade to the vessel’s engine-control system to MAN Energy Solutions’ latest Triton system. Following the completion of sea-trials, Maersk Halifax has returned to operation and is now servicing A.P. Moller-Maersk’s (Maersk) Trans-Pacific trade. Leonardo Sonzio, Head of Fleet Management and Technology at Maersk, said: "Since we set the ambitious climate goal of reaching net zero emissions by 2040, we have explored the potential in retrofitting existing vessels with dual-fuel engines. In the coming year, we will take learnings from this first conversion of a large vessel. Retrofits of existing vessels can be an important alternative to new builds in our transition from fossil fuels to low-emission fuels." Reduce CO2 emissions Maersk has already placed a preorder for MAN PrimeServ to convert an additional 10 vessels The Halifax retrofit is expected to serve as a blueprint for future retrofit projects. Indeed, Maersk has already placed a preorder for MAN PrimeServ to convert an additional 10 vessels from its fleet to methanol operation. Michael Petersen, Senior Vice President and Head of PrimeServ Denmark, praised the project collaboration with Maersk and Asia Pacific and said: "Retrofits are one of the five growth areas identified in MAN Energy Solutions’ ‘Moving Big Things To Zero’ strategy, enabling shipowners to drastically reduce CO2 emissions without having to commission newbuilds. Retrofitted engines are able to switch between fuels with minimal disruption, flexibility that is crucial for maintaining operational efficiency and reliability." Shipping towards decarbonisation Michael Petersen added: "At PrimeServ, we estimate that more than 4,000 existing marine engines have the potential to be converted to operation on green fuels like e-methanol and e-methane." Speaking at a recent event at Asia Pacific Dockyard in Zhoushan to mark the project’s conclusion, Sarath Prasannan, Senior Vice President and Head of Region Asia Pacific, said: "This groundbreaking project marks a pivotal moment in the shipping industry's journey towards decarbonisation. We hope that China's policies and infrastructure will continue to foster an environment where shipyards can carry forward this commendable work."

Insights & Opinions from thought leaders at MAN Energy Solutions

Ammonia is gaining traction as a future fuel in the maritime industry, primarily due to its potential to significantly reduce greenhouse gas emissions. A key driver for ammonia's interest is that it can be carbon-free when combusted, which aligns with the maritime industry's increasing pressure to meet emissions regulations. However, most ammonia production currently relies on fossil fuels. Transitioning to "green ammonia" production is crucial for sustainability. If "green ammonia" is produced using renewable energy sources, it offers a pathway to near-zero emissions shipping. Safety measures and regulations Ammonia’s volumetric energy density – higher than hydrogen – makes it more practical for onboard storage. However, ammonia is toxic, which requires stringent safety measures and regulations for handling and storage. The combustion of ammonia can produce nitrous oxide (N2O), a potent greenhouse gas. Therefore, mitigation technologies are needed. Building the necessary infrastructure for ammonia bunkering and supply will be a significant undertaking. Developing guidelines for safe use Ammonia is poised to play a significant role in the maritime industry's transition to a future The International Maritime Organization (IMO) is developing guidelines for the safe use of ammonia as a marine fuel. Increasing numbers of companies are investing in the development of ammonia-fueled vessels and technologies. European Union (EU) legislation, such as the EU Emissions Trading System (ETS) and the FuelEU initiative to support decarbonisation, are pushing the maritime industry towards the use of alternative fuels, which is increasing the potential of ammonia. While challenges remain, ammonia is poised to play a significant role in the maritime industry's transition to a more sustainable future. Ongoing research and development Ongoing research and development are focused on improving safety, reducing emissions, and scaling up production. In essence, ammonia offers a promising pathway for the maritime industry to reduce its carbon footprint, but its widespread adoption depends on overcoming technical and logistical challenges. Working toward the future of ammonia Progress is already happening as the maritime industry works toward a future that includes the use of ammonia as a fuel. For example, one project underway aims to be a pioneer in establishing a comprehensive and competitive supply chain to provide clean ammonia ship-to-ship bunkering in the U.S. West Coast. Progress is already occurring as the maritime industry works toward a future A feasibility study is being conducted at the Port of Oakland, Benicia, and nearby major ports on the U.S. West Coast. A Memorandum of Understanding (MOU) between American Bureau of Shipping, CALAMCO, Fleet Management Limited, Sumitomo Corp. and TOTE Services LLC is jointly conducting the feasibility study. "We are proud to share our industry-pioneering expertise in ammonia as a marine fuel to support this study on the U.S. West Coast,” said Panos Koutsourakis, Vice President of Global Sustainability at the American Bureau of Shipping. “Our expertise in developing safety guidelines will support the consortium to address the ammonia-specific set of safety and technology challenges.” More global ammonia developments In another development, three LPG/ammonia carrier ships have been ordered at the South Korean shipyard HD Hyundai Heavy Industries (HD HHI). Danish investment fund European Maritime Finance (EMF) and international shipping company Atlas Maritime have confirmed the order. HD HHI’s parent company, HD Korea Shipbuilding & Offshore Engineering (HD KSOE), revealed the order for $372 million in March 2024. The three 88,000 cubic-metre LPG dual-fuel carriers, capable of carrying and running on ammonia, are scheduled for delivery in December 2027. The vessels will be named EMF Viking I, II, and III. Also, Lloyd’s Register (LR) and Guangzhou Shipyard International have signed a joint development project to design the world’s largest very large ammonia carrier (VLAC). The design of the 100,000-cubic-metre vessel has been assessed in line with LR’s Structural Design Assessment and prescriptive analysis. The gas carrier will have an independent IMO Type B tank for safe carriage of the chemical. Zero-emissions operations The cargo ship, which will be 7,800 dwt, is designed to transport timber from Norway to Europe “As major economies look to co-fire ammonia in their coal power stations to reduce the CO2 footprint of their national energy mix, shipping will play a key role in distributing clean hydrogen-based commodities such as ammonia, thereby supporting nations to meet their Paris Agreement commitments," says LR's Chief Executive Nick Brown. Furthermore, a partnership of companies from Norway has ordered a pioneering short-sea cargo ship that will advance the industry’s ability to provide zero-emissions operations. The cargo ship, which will be 7,800 dwt, is designed to transport timber from Norway to Europe and will be the first to operate on ammonia and electricity. Amogy’s ammonia-to-electrical power system A start-up company focusing on ammonia-to-power technology, Amogy, demonstrated the first tugboat powered by its cracking technology just short of the fourth anniversary of the company’s launch. The trip of a 67-year-old tug along a tributary of New York State’s Hudson River is part of the company’s works to develop and commercialise its technology to decarbonise the most difficult industries. Amogy’s ammonia-to-electrical power system splits, or “cracks,” liquid ammonia into its base elements of hydrogen and nitrogen. The hydrogen is then funnelled into a fuel cell, generating the power for the vessel. Research points to the risks of ammonia The chemical, made of hydrogen and nitrogen, can also be burned as a zero-carbon fuel Today and in the future, ammonia, a main component of many fertilisers, can play a key role in a carbon-free fuel system as a convenient way to transport and store clean hydrogen. The chemical, made of hydrogen and nitrogen, can also be burned as a zero-carbon fuel. However, new research led by Princeton University scientists illustrates that even though it may not be a source of carbon pollution, ammonia's widespread use in the energy sector could pose a grave risk to the nitrogen cycle and climate without proper engineering precautions. Use of ammonia U.S. National Science Foundation (NSF)-supported research found that a mismanaged ammonia economy could ramp up emissions of nitrous oxide, a long-lived greenhouse gas around 300 times more potent than carbon dioxide and a major contributor to the thinning of the stratospheric ozone layer. The use of ammonia could lead to substantial emissions of nitrogen oxides, a class of pollutants that contribute to the formation of smog and acid rain. And it could directly leak fugitive ammonia emissions into the environment, forming air pollutants, impacting water quality and stressing ecosystems by disturbing the global nitrogen cycle. Negative impacts of an ammonia economy The researchers found that the potential negative impacts of an ammonia economy "We have great hope that ingenuity and engineering can help reduce our use of carbon-based energy sources," said Richard Yuretich, a program director in NSF's Division of Earth Sciences. "But caution is advised because of unintended environmental spillover effects that may result from new technology." The researchers found that the potential negative impacts of an ammonia economy may be minimised with proactive engineering practices, but the possibility of risks should not be taken lightly. Addressing an inconvenient reality As interest in hydrogen as a zero-carbon fuel has grown, so too has an inconvenient reality: It is notoriously difficult to store and transport over long distances, requiring storage at either temperatures below -253 degrees Celsius or at pressures as high as 700 times atmospheric pressure. Ammonia, on the other hand, is much easier to liquify, transport and store, and capable of being moved around similarly to tanks of propane. Nonetheless, the cycle of nitrogen is delicately balanced in Earth's critical zone, and extensive research must be undertaken to investigate the repercussions of ammonia combustion and to develop new methods to minimise the risks. Challenges of ammonia as a maritime fuel Here's a breakdown of the key challenges of using ammonia for maritime fuel: Toxicity and Safety: For human health, ammonia is highly toxic, posing a serious risk to human health through inhalation or skin contact. This necessitates stringent safety protocols, advanced leak detection systems, and thorough crew training. Relating to the environment, leaks can also harm aquatic ecosystems, requiring robust containment and mitigation measures. Combustion Challenges: Ammonia's combustion characteristics are less favourable than traditional fuels, requiring modifications to engine design and potentially the use of pilot fuels. Emissions: Combustion can produce nitrogen oxides (NOx) and nitrous oxide (N2O), both of which are harmful pollutants. Mitigating these emissions is crucial. "Ammonia slip" is also a concern, in which unburnt ammonia is released. Infrastructure and Supply Chain: Establishing a global network of ammonia bunkering infrastructure is a massive undertaking, requiring significant investment and coordination. Scaling up "green ammonia" production, using renewable energy, is essential for its sustainability. This requires a robust and reliable supply chain. Storage: Ammonia has specific storage requirements, and onboard storage systems must be designed for safety and efficiency. International Standards Needed: Consistent and comprehensive international regulations and standards are needed for the safe handling, transportation, and use of ammonia as a marine fuel. While the IMO is developing Guidelines, complete and ratified rules are still needed. Economic challenges: "Green ammonia" is currently more expensive than traditional fuels, although costs are expected to decrease as production scales up. Significant investments are needed in research, development, and infrastructure to make ammonia a viable maritime fuel. Also, dedicated ammonia-fueled engines are still under heavy development, and do not have widespread availability. The path to commercialisation Overcoming the variety of technical and other obstacles will require collaboration among governments, industry stakeholders, and research institutions. The timeline for ammonia deployment in maritime applications is actively unfolding, with key milestones happening now and soon. 2025 marks the first trials of two-stroke, ammonia dual-fuel engines on oceangoing ships. Engine manufacturers like MAN Energy Solutions and WinGD are progressing with their engine development, with initial deliveries soon. These pilot projects are crucial for gathering real-world data and building confidence in ammonia as a marine fuel. Development of comprehensive regulations As the maritime industry faces, ammonia is hoped to play a growing role in the fuel mix Gradual commercialisation will follow in the late-2020s as the technology matures and the infrastructure develops. The focus will be on refining engine technology, improving safety protocols, and establishing bunkering facilities in key ports. Wider adoption will likely follow in the 2030s, depending on factors such as the cost of green ammonia, the development of comprehensive regulations, and the expansion of the global supply chain. As the maritime industry faces increasing pressure to decarbonise, ammonia is expected to play a growing role in the fuel mix. Future of maritime It's likely that a combination of ammonia and other alternative fuels and technologies will be used in the future of maritime. Alternatives include methanol, liquid natural gas (LNG), hydrogen, biofuels, electric propulsion, and even nuclear power. Ammonia is a strong contender, bit it faces stiff competition from other promising technologies. The maritime industry's transition to a sustainable future will likely involve a diverse mix of fuel solutions.

As regulations on emissions become more stringent, more companies and organisations in the maritime industry will likely start to use methanol as a cleaner and more sustainable fuel. Methanol Methanol is a promising alternative fuel for the maritime industry due to its potential to reduce greenhouse gas emissions, increase energy security, and improve air quality. The future of methanol as a maritime fuel depends on several factors, including regulatory policies, technological advancements, and the availability and cost of methanol. Production One of the main advantages of methanol as a maritime fuel is that it can be produced from a variety of renewable and non-renewable sources, such as natural gas, coal, and biomass. Methanol can be produced using CCU technologies, which can help reduce the carbon footprint Methanol can also be produced using carbon capture and utilisation (CCU) technologies, which can help reduce the carbon footprint of the maritime industry. In addition, methanol is relatively easy to transport and store, making it an attractive option for use in marine vessels. Availability Methanol can be stored at room temperature and can be transported using existing infrastructure, such as pipelines and tankers. The availability of methanol at ports is an issue. In 2020, the Methanol Institute confirmed that methanol is already available in more than 100 ports around the globe and that 47 of those ports have storage facilities of over 50,000 metric tons. A further 66 ports are also storing methanol. Use of methanol in reducing GHGs Methanol can reduce greenhouse gas emissions and meet new emissions regulations when used as a marine fuel in various ways, including: Blending with marine diesel oil (MDO): Methanol can be blended with MDO to produce Methyl Diesel Fuel (MDF). MDF can be used in compression ignition engines that typically run on MDO or heavy fuel oil. Direct injection: Methanol can also be used as a direct injection fuel. In this case, methanol is injected into the engine’s combustion chamber and burned as the primary fuel. Methanol can be used in both spark-ignited and compression-ignited engines. Dual-fuel engines: Methanol can also be used in dual-fuel engines. In this case, methanol is injected into the combustion chamber along with another fuel, such as diesel. Diesel acts as the pilot fuel to ignite the methanol, which is burned as the primary fuel. Pros and cons Methanol is highly toxic and flammable, so it requires careful handling and storage to ensure safety One advantage of using methanol as a maritime fuel is that it has a high-octane rating, which can improve engine performance. Methanol is also relatively easy to produce, and it can be made from renewable sources such as biomass. However, methanol is highly toxic and flammable, so it requires careful handling and storage to ensure safety. Environmental benefits Methanol has several environmental advantages over traditional maritime fuels such as heavy fuel oil and marine diesel oil. These advantages include: Lower greenhouse gas emissions: Methanol has a lower carbon content than traditional maritime fuels, which means it produces fewer greenhouse gas emissions when burned. Methanol can reduce greenhouse gas emissions by up to 15% compared to traditional fuels. Reduced air pollution: Methanol also produces fewer emissions of harmful air pollutants such as nitrogen oxides (NOx) and particulate matter (PM) when burned. Methanol can reduce NOx emissions by up to 60% and PM emissions by up to 95% compared to traditional fuels. Biodegradability: Methanol is biodegradable, which means it can break down naturally in the environment. This is important in case of any accidental spills or leaks that may occur during fuel handling and transportation. Renewable source: Methanol can be produced from renewable sources such as biomass, which means it can be a sustainable alternative to traditional maritime fuels. Energy efficiency: Methanol has a high energy content per unit of weight, which means it can provide more energy per unit of fuel compared to traditional fuels. This can lead to improved energy efficiency and lower fuel consumption. Maritime applications Stena Line has converted one of its ferries, the Stena Germanica, to run on methanol Overall, using methanol as a maritime fuel can help reduce the shipping industry's environmental impact and promote more sustainable and responsible practices. Several companies and organisations have started using methanol for maritime applications. Stena Line, a Swedish ferry operator, has converted one of its ferries, the Stena Germanica, to run on methanol. The ferry operates between Kiel, Germany, and Gothenburg, Sweden. Nominal capacity In addition, Maersk Line, the world's largest container shipping company, has announced plans to use methanol as a marine fuel. In October 2022, Maersk announced it has ordered a further six large ocean-going vessels that can sail on green methanol. The six vessels will be built by Hyundai Heavy Industries (HHI) and have a nominal capacity of approximately 17,000 containers (Twenty Foot Equivalent - TEU). They will replace the existing capacity in the Maersk fleet. With the order, Maersk has in total ordered 19 vessels with dual-fuel engines able to operate on green methanol. Methanol engines MAN Energy Solutions, a provider of marine engines, has developed methanol engines for use in maritime applications. The engines can be used in both propulsion and auxiliary power applications. Methanol-based two- and four-stroke solutions will be relevant for the complete MAN Energy Solutions marine engine portfolio. Typical examples of the application of four-stroke engines include container ships, ferries, fishing or cruise vessels, as well as offshore solutions. Future adoption Adoption of methanol will depend on cost, availability, and the development of regulatory frameworks Stationary solutions might also be a possible area for methanol applications, for example, for small islands that lack natural gas infrastructure. However, the wider adoption of methanol as a maritime fuel will depend on several factors, including the cost of methanol production, the availability of methanol infrastructure, and the development of regulatory frameworks to support its use. Nevertheless, the future of methanol as a maritime fuel looks promising, as it offers a potential solution to the maritime industry's environmental and energy security challenges. Flexible in use Battery electric propulsion is another potential alternative to traditional maritime fuels, but it is limited by the current state of battery technology, which makes it difficult to achieve long-distance, large-scale shipping operations. Methanol can offer a longer range and greater flexibility than battery electric propulsion while still reducing emissions. Overall, while methanol is not a perfect solution, it offers several advantages over other maritime fuels and has the potential to play a significant role in reducing the environmental impact of the shipping industry.