MacGregor - Experts & Thought Leaders

Latest MacGregor news & announcements

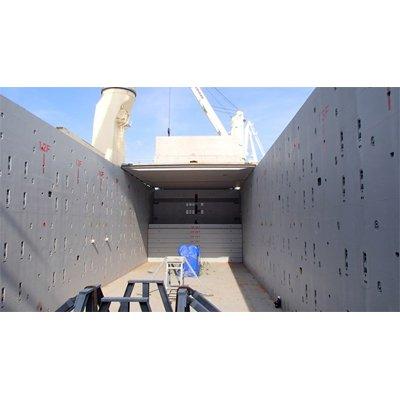

MacGregor has secured an order from Hapag-Lloyd for its fully automatic twistlocks (ACV-1) “Hippo”, designed to improve cargo handling efficiency. Twistlocks are used to secure containers on ships, ensuring stability and safety during transport. This order will support Hapag-Lloyd’s A19-series ships, which include six 19,900 TEU vessels: Al Nefud, Al Dahna Express, Barzan, Al Muraykh, Al Zubara, and Tihama. The order was booked in the first quarter 2025. The first set of Hippos is planned to be delivered beginning the second quarter of 2025 and to be completed by the fourth quarter of 2026. Collaboration between MacGregor and Hapag-Lloyd This order highlights the collaboration between MacGregor and Hapag-Lloyd to increase cargo capacity This order highlights the collaboration between MacGregor and Hapag-Lloyd to increase cargo capacity, enhance operational efficiency, and reduce environmental impact. With this action, Hapag-Lloyd aims to improve cargo operations while reinforcing its leadership in the competitive container shipping market. "At Hapag-Lloyd, we continuously strive for innovative solutions that further advance efficiency in our operations. MacGregor’s Hippo fully automatic twistlocks align perfectly with our commitment to operational excellence," says Dr.-Ing. Christoph Thiem, Director Fleet Innovation & Technology, Hapag-Lloyd. "We look forward to seeing these Hippos in action and further strengthening our long-term partnership with MacGregor." Strengthening the partnership "We are proud to further strengthen our partnership with Hapag-Lloyd by delivering innovative and reliable fully automatic twistlocks that meet their high operational standards," says Magnus Sjöberg, Senior Vice President, Equipment and Solutions Division, MacGregor. "This order underscores our commitment to supporting Hapag-Lloyd’s success and leadership in the industry." Commitment to innovation and collaboration MacGregor continues to develop advanced cargo securing solutions for the container shipping segment With a strong commitment to innovation and collaboration, MacGregor continues to develop advanced cargo securing solutions for the container shipping segment, tailored to the evolving needs of the industry. This includes lashing equipment, which consists of rods, turnbuckles, and other securing devices that keep containers safely in place during transport. This latest order further solidifies MacGregor’s position as a trusted partner in delivering high-quality, efficient, and safe container handling solutions for global shipping companies.

MacGregor has secured a contract to supply an advanced anchor handling towing winch (AHTW) package for a series of SPA90 (90T BP AHTS ABS Class) anchor handling tug supply (AHTS) vessels owned by SINOPACIFIC Engineering & Contracting Co Ltd (SPEC). The MacGregor AHTW package is designed to support the complex operations of SPA90, ensuring precision, safety, and operational efficiency in all offshore conditions. The MacGregor scope of supply includes anchor windlass with roller chain stoppers, anchor handling towing winch with dynamic lowering and hydraulic spooling device, tugger winches, capstans, and a power pack. It also includes 250T shark jaws towing pins. SPA90 The SPA90 is a diesel-electric (battery hybrid optional) shallow draft AHTS designed for worldwide operation The first batch of winches is scheduled for delivery in April 2026, ensuring timely integration into the vessel's construction schedule. The SPA90 is a diesel-electric (battery hybrid optional) shallow draft AHTS designed for worldwide operation, particularly in West Africa, the Middle East, and Southeast Asia. Choosing MacGregor "We chose MacGregor for this project because of the company’s proven expertise and track record, especially in GPA 254, GPA654 and SPA80 series since 2010,” says Mr. Zhang Yao, Vice General Manager, SINOPACIFIC Engineering & Contracting Co Ltd. “MacGregor’s equipment has proven to be high-performance and operationally efficient. Additionally, MacGregor’s global installed base provides good after-sales service, which was our main consideration. We look forward to working with MacGregor on the successful completion of a highly significant project for our new SPA90 series.” Words from MacGregor SVP “MacGregor is proud to support the next generation of anchor handling tug supply vessels with our effective solutions. Our equipment is designed to maximise efficiency and safety while ensuring reliable operations in demanding offshore environments,” says Magnus Sjöberg, Senior Vice President, Equipment and Solutions Division, MacGregor. “The latest contract offers tangible evidence of MacGregor’s position as a preferred partner for these high-performance vessels. By delivering superior quality and reliable solutions, MacGregor will continue to play a vital role in advancing the offshore energy sector,” he concludes.

Event location Webinar (9 CET and 16 CET) Event date 20 May 2025 Join them for the GravityVibe Webinar on 20 May. Discover how MacGregor’s GravityVibe self-unloading system is setting a new standard in bulk cargo handling. On 20 May, they will host two webinar sessions to suit different time zones: Session 1: 09:00 CEST | 15:00 SGT/CST Session 2: 10:00 EDT | 16:00 CEST | 22:00 SGT/CST Key benefits of GravityVibe In this upcoming webinar, MacGregor’s experts will share the latest results from the full-scale test rig, providing real-world validation of the GravityVibe self-unloading system. They will focus on demonstrating the key benefits of GravityVibe, including enhanced efficiency, improved safety, and reduced environmental impact in bulk cargo operations. Reserve the spot and learn how GravityVibe is shaping the future of bulk unloading.

Insights & Opinions from thought leaders at MacGregor

Given the diverse stakeholders in the maritime industry, it is understandable that collaboration is a challenge. However, the interconnected ecosystem of maritime makes collaboration essential. From ship owners and operators to port authorities, from shippers to shipbuilders, from classification societies to marine service providers and others, there are vast opportunities to work together and cooperate. To gain insight, we asked our Expert Panel Roundtable: How can the maritime industry increase collaboration, and what are the benefits?

Traditionally, bulk cargo unloading has faced challenges around operational efficiency, safety risks, environmental impacts, and high operational costs. Rough discharges, equipment wear, vibration damage, and limited weather operating windows have all constrained vessel utilisation and performance. Moreover, older unloading systems are energy-intensive and labour-dependent, increasing both costs and environmental footprint. Cargo unloading systems Many bulk cargo unloading systems depend on steep slope angles, which limit the types of materials that can be carried efficiently. MacGregor’s GravityVibe directly addresses this factor by allowing efficient discharge with significantly lower slope angles, thus broadening the range of cargo that can be handled. Many bulk cargo unloading systems depend on steep slope angles. Ship structures and unloading equipment “GravityVibe reduces reliance on gravity alone by augmenting the flow with controlled vibration,” says Mikael Hägglund, Senior Manager, Cranes at MacGregor. “This approach improves operational efficiency, enhances safety through more predictable material flow, and reduces wear on ship structures and unloading equipment.” Challenges of space utilisation and cargo versatility MacGregor is a provider of cargo and load handling solutions to maximise efficiency Additionally, the GravityVibe system will, in most cases, require only one hold conveyor and no cross conveyor in the hold, making the operations both cost-effective and sustainable, says Hägglund. MacGregor, based in Helsinki, Finland, is a provider of cargo and load handling solutions to maximise efficiency of maritime operations. As an augmented gravity self-unloading system, GravityVibe enhances cargo flow using vibration, enabling bulk materials to be discharged efficiently at lower slope angles (15–20 degrees). It reduces material blockages and optimises discharge without requiring steep holds, addressing the challenges of space utilisation and cargo versatility. Mechanical strain on vessel structures The system lessens mechanical strain on vessel structures, and supports safer, smoother, and more efficient operations across different cargo types. “Using lower slope angles allows ships to maximise cargo hold volume and transport a wider variety of bulk materials, including those that would not flow well with conventional systems,” says Hägglund. “It improves operational flexibility.” Integrity of the vessel Vessels benefit from a more compact and efficient hold design, optimising stability and construction Structurally, vessels benefit from a more compact and efficient hold design, optimising stability and potentially lowering construction and maintenance costs, adds Hägglund. “Managing vibration and sound levels is critical for maintaining the structural integrity of the vessel and ensuring crew safety and comfort,” he says. “Excessive vibration can lead to accelerated wear on ship components and fatigue damage over time.” GravityVibe’s design GravityVibe’s design ensures that both vibration and sound levels stay well below class-defined thresholds, preserving vessel longevity and reducing long-term maintenance and repair costs. Bulk cargoes have widely varying properties such as particle size, cohesiveness, moisture content, and chemical reactivity, all of which impact flow behaviour. Sticky, wet, or coarse materials require different unloading strategies to avoid blockages, segregation, or structural strain. Bulk cargoes have widely varying properties like particle size and cohesiveness. Broader spectrum of cargo types Key elements to achieve automation include fine-tuning self-optimisation algorithms GravityVibe’s vibration-driven approach adapts to these material differences, maintaining consistent discharge rates and ensuring operational reliability across a broader spectrum of cargo types without manual intervention or excessive mechanical modification, says Hägglund. More automated systems are on the horizon. Fully automated discharge is rapidly approaching reality, thanks to intelligent unloading systems like GravityVibe. Key remaining elements to achieve automation include fine-tuning self-optimisation algorithms, integrating predictive maintenance solutions, and standardising automation interfaces between vessels and ports. GravityVibe features MacGregor is actively working to refine onboard software, improve material recognition capabilities, and enhance real-time adjustment features. Wider industry adoption and regulatory frameworks are also crucial for achieving fully autonomous and seamless bulk unloading. GravityVibe features a built-in self-optimisation system that uses sensors to monitor material flow characteristics during discharge. Based on live data, it automatically adjusts vibration frequency and intensity to match the properties of each specific cargo, ensuring optimal unloading performance without manual recalibration. MacGregor is working to refine onboard software and improve material recognition. GravityVibe’s performance GravityVibe’s performance has been verified through a combination of laboratory studies MacGregor is fine-tuning this system by gathering real-world data from full-scale test rigs, analysing operational performance across various cargo types, and incorporating feedback loops to continually improve discharge efficiency and system responsiveness. Real-world validation is essential to prove that unloading systems perform reliably under operational conditions. GravityVibe’s performance has been verified through a combination of laboratory studies and full-scale rig testing. In-house tests and studies For example, validation by bulk solids researcher TUNRA showed efficient unloading across diverse materials such as wood chips, manufacturing sand, and gravel. In-house tests and studies with external specialists like KTH have confirmed low vibration levels, consistent discharge flow, and high operational reliability, providing strong evidence for commercial deployment. TUNRA showed efficient unloading across diverse materials such as sand. GravityVibe’s system design GravityVibe’s system design is based on long-lasting parts and improved cargo flow High maintenance requirements traditionally have led to significant downtime and increased operational costs. GravityVibe’s system design is based on long-lasting components and improved cargo flow that reduce risks for failures and needed service, thereby lowering maintenance costs/needs. “With real-time monitoring and smart diagnostics, potential issues can be detected and addressed before they escalate, minimising service interruptions,” says Hägglund. “This proactive approach enhances equipment availability and ensures better operational continuity for vessel operators.” MacGregor GravityVibe system When unloading standard bulk carriers, there is a need to clean the holds with manpower and external machines as the port cranes or the vessel cranes will not be able to empty the holds. The weather could also be a factor for delay in cases where the cargo is sensitive to water. For the MacGregor GravityVibe system, all material will be removed from the hold without any extra efforts. GravityVibe demonstrates that with intelligent use of vibration and lower slope angles can achieve the same — or even better — results. This approach not only enables broader cargo flexibility but also reduces structural stress, energy consumption, and environmental footprint.

Achieving optimal return on investment (ROI) for a maritime company involves a strategic combination of operational efficiency, revenue enhancement, cost control, careful financial management, attention to sustainability and regulatory compliance, and other factors. Given all the variables in play, profitability can be elusive, but our Expert Panel Roundtable has some ideas. We asked: How can maritime companies maximise return on investment (ROI)?