Imabari Shipbuilding Co., Ltd. - Experts & Thought Leaders

Latest Imabari Shipbuilding Co., Ltd. news & announcements

The University of Osaka (President: Atsushi Kumanogoh), in collaboration with Imabari Shipbuilding Co., Ltd. (President: Yukito Higaki, 'Imabari Shipbuilding'), Japan Marine United Corporation (President: Takashi Hirose, 'JMU'), Nippon Kaiji Kyokai (President & CEO: Hayato Suga, 'ClassNK'), and MTI Co., Ltd. (President: Hideki Suzuki, 'MTI') will establish the Open Collaboration Laboratory for Enabling Advanced Marine Systems (OCEANS) at the Techno Alliance Building within the Graduate School of Engineering at The University of Osaka in April 2025. Japan’s maritime industry In addition, Nihon Shipyard Co., Ltd. (President: Kiyoshi Higaki, hereinafter referred to as 'NSY'), a sales and design company owned by Imabari Shipbuilding and Japan Marine United Corporation (JMU), will also cooperate with this program. NSY will actively participate in the design and engineering research activities led by OCEANS. This initiative aims to promote the global competitiveness of Japan’s maritime industry. The attention to the OCEANS initiative is greatly appreciated. Background and objectives of collaboration Japanese maritime industry is being called upon to make revolutionary change In an era of unprecedented change, driven by rising geopolitical risks, growing awareness of economic security, climate change, the rapid development of technologies such as AI and their social impact, and the ageing population in developed countries, the Japanese maritime industry is being called upon to make revolutionary transformation. A major revolution in design and manufacturing processes is needed to quickly supply high-performance next-generation ships that embody innovative functions, excellent environmental performance and safety features, to customers. Advanced systems engineering and cutting-edge AI technologies This collaboration, established under the 'Industry on Campus' program promoted by The University of Osaka, integrates diverse engineering fields such as ship hydro and structural dynamics, propulsion, electrical systems, and control systems. Leveraging advanced systems engineering and cutting-edge AI technologies, this initiative also serves as a hub for education and training of the next generation of talent. For Japan, which is surrounded by sea, the maritime industry, that supplies and operates ships for marine transportation is fundamental for social and economic stability and people’s living. Japan’s shipbuilding industry is highly regarded worldwide for its design and construction technologies. International maritime safety standards and criteria The shipping industry has one of the world’s largest fleets and excellent safe and efficient carrier technologies The shipping industry has one of the world’s largest fleets and excellent safe and efficient transportation technologies. The classification society develops classification rules and conducts certification services for safe and efficient marine transportation, and the number of ships certified by it is one of the highest in the world. The Graduate School of Engineering at The University of Osaka, particularly its Department of Naval Architecture and Ocean Engineering, has achieved global recognition for its research on ships and marine structures. The department has contributed significantly to international maritime safety standards and criteria, collaborating with leading companies and fostering interdisciplinary, advanced research. Net-zero greenhouse gas (GHG) emissions International shipping has set a goal to achieve net-zero greenhouse gas (GHG) emissions by around 2050, with Japan’s maritime industry expected to play a crucial role in achieving this target. In addition to the essential transition to alternative fuels for GHG reduction, advancements in ship automation technologies are anticipated to progress further. This will undoubtedly lead to increased complexity in the processes of design, construction, certification, and operation. To address these challenges, innovative systems engineering leveraging cutting-edge technologies such as AI will be indispensable for the future of the maritime industry. This research laboratory will undertake these studies, contributing to the enhancement of the global competitiveness of Japan’s maritime industry. Collaborative research program The top goal is to prove itself as a research and academic hub that drives the maritime industry forward This collaborative research program leverages the strengths of Japan's world-renowned maritime industry cluster, including shipbuilding, shipping, and ship classification. By deepening industry-academia collaboration, it aims to enhance international competitiveness, advance world-class research, and foster talent development. The ultimate goal is to establish itself as a pioneering research and educational hub that drives the global maritime industry forward. Overview of the laboratory Name: Open Collaboration Laboratory for Enabling Advanced Marine Systems (OCEANS) Duration: April 1, 2025 – March 31, 2030 (5 years) Location: Techno Alliance Building A 804-806, The University of Osaka Faculty and Research Team (As of April 1, 2025) Full-Time Faculty: Specially Appointed Assoc. Prof. Yasuo Ichinose, Specially Appointed Asst. Prof. Kouki Wakita Part-Time Faculty: Prof. Atsuo Maki, Prof. Kazuhiro Iijima, Prof. Munehiko Minoura, Prof. Naoki Osawa, Assoc. Prof. Akira Tatsumi, Assoc. Prof. Masahiro Sakai, Asst. Prof. Takayuki Takeuchi Visiting Faculty: Visiting Prof. (currently being selected), Visiting Assoc. Prof. (currently being selected) Researchers from participating companies: Approximately 10 researchers Research focus areas Basic research on innovative systems engineering and design automation Resilience of the supply chain for stable marine transportation Application of AI in ship basic design, function design, and certification Production design and digital shipyards Digital twin technologies in ship operation and maintenance Individual studies on design, construction, operation, and certification, including both open and closed research projects Education and training for the next generation of maritime industry experts

Japanese maritime experts have announced the successful completion of the early phases of a cross-industry project aimed at creating a secure data-sharing framework between shipyards and ship owners to advance the use of digital twins throughout a ship’s lifecycle. The project, which aims to enable the use of a vessel’s unique design data to optimise efficiency and safety at sea, as well as the sharing of operational data to inform new designs, brings together ship owners - NYK Group company, MTI Co. Ltd. (“MTI”), Mitsui O.S.K. Lines, Ltd. (MOL) and Marubeni Corporation, and shipbuilders - Imabari Shipbuilding, Japan Marine United Corporation, and Usuki Shipyard, along with software and data services provider - NAPA, and classification society - ClassNK. Feasibility of increased data sharing Initial results have confirmed the feasibility of increased data sharing between shipyards, ship owners Initial results have confirmed the feasibility of increased data sharing between shipyards, ship owners, ship managers and charterers, among other stakeholders, by overcoming obstacles related to the sharing of sensitive design and operational data. The first two phases of the project identified over 30 potential use cases where the data and 3D models used to design the ship can be shared securely and used to create a vessel-specific digital twin that helps improve operational efficiency and safety throughout its lifecycle. Value of digital twins in supporting loading calculations Further analysis confirmed the potential and value of digital twins in supporting loading calculations, ship condition monitoring and energy-saving device evaluation. Building on the success of the feasibility study, the next phase will develop a new platform that will enable 3D models created during the design stage to be shared in a secure and access-controlled digital environment, together with new business models to implement this innovative approach in practice in commercial agreements. New revenue stream for shipyards and solution providers This could create a new revenue stream for shipyards and solution providers, as well as mechanisms to share benefits between stakeholders. This phase of the project is led by ClassNK as an impartial entity to ensure that the platform is neutral and fair. The project aims to start operation in 2025, signaling a potential breakthrough in the sharing of design and operational data to overcome traditional barriers to the adoption of digital twins in the maritime sector. Partnership to help improve future ship designs The partnership also explored ways in which operational data can be fed back to shipyards The partnership also explored ways in which operational data can be fed back to shipyards to provide valuable insights on how their concepts perform in real life, thereby enabling naval architects and engineers to improve future ship designs. Mr. Naoki Mizutani, Executive Vice President for NAPA Studios, said: “Collaboration continues to be the underpinning foundation enabling the industry to develop new solutions and optimise existing operations for the energy transition.” Bridging design and operational data for safer shipping Naoki Mizutani adds, “Our Digital Twin project captures this enterprising spirit to reach a new milestone: bridging design and operational data for safer, more efficient and greener shipping.” He continues, “This project also demonstrates that it is possible to build new types of partnerships with stakeholders across the value chain to make the most of industry expertise and maximise the potential of technologies at our fingertips.” Digital twins are a key asset for shipping Mr. Yoshimichi Sasaki, General Manager, Digital Transformation Center at ClassNK, said: “Digital twins are a key asset for shipping, particularly in the context of the energy transition.” He adds, “They offer unparalleled insight into a ship’s unique design profile and characteristics, and unlock new opportunities to use this data to optimise operations and maintenance, while also expanding possibilities to deploy innovative technologies on board.” Yoshimichi Sasaki continues, “This project demonstrates how we can break data silos to foster closer dialogue between shipyards and ship owners at a time of increasing design and operational complexity.”

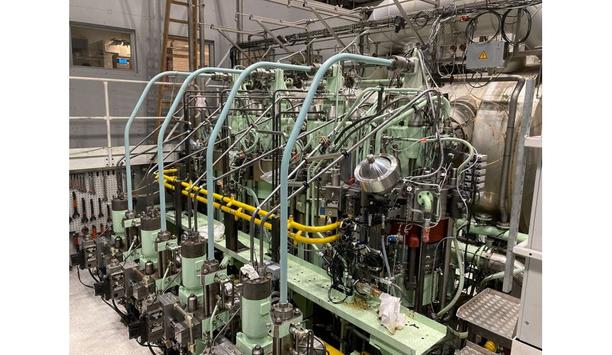

Imabari Shipbuilding will install an MAN B&W 7S60ME-Ammonia engine with SCR in connection with the construction of a 200,000 dwt class bulk carrier for a joint venture between K Line, NS United and Itochu Corporation. The business represents one of the first projects for MAN Energy Solutions’ ammonia-powered engine that is currently under development in Denmark. MITSUI E&S will build the engine in Japan. MAN B&W 7S60ME-Ammonia engine installation Brian Østergaard Sørensen, Vice President and Head of Research & Development, Two-Stroke at MAN Energy Solutions, said: “This project marks another important milestone in our ammonia-engine development and indeed for the maritime industry in general.” He adds, “It also confirms that we are on the right track in relation to our dual-fuel ammonia concept where we have gained a great understanding of ammonia’s unique characteristics as a marine fuel via our two-stroke engine testing, which we started in early June 2023. Equally as important, we are confident of how to handle it safely; it is very satisfying to see our hard work beginning to pay off.” High interest in this revolutionary engine Bjarne Foldager – Country Manager, Denmark – MAN Energy Solutions, said: “The interest in this revolutionary engine had been overwhelming, even prior to our two-stroke ammonia-engine testing, but has even intensified after the important lessons learnt from ammonia-combustion testing on the test engine here in Copenhagen.” He adds, “While the current growth in shipping will increase greenhouse-gas emissions, alternative fuels like e-methanol, e-methane and green ammonia will eventually come to compete with fossil fuels, but we need regulation to encourage their adoption in the industry.” Carbon neutrality goal for 2050 Bjarne Foldager continues, “Regulatory clarity from the EU and IMO is improving, but now we need the right market-based tools to be introduced, in order to bring the industry towards carbon neutrality for 2050.” Thomas S. Hansen, Head of Sales and Promotion, MAN Energy Solutions, said: “MAN Energy Solutions has developed this engine since 2019 with over 100,000 man-hours recorded in that time. This first MAN B&W ammonia engine is a 60-bore type, which is applicable to a broad range of vessel segments. We believe that the success of ammonia as a marine fuel strongly relies on a safe introduction to the market.” He adds, “We will, therefore, monitor a number of engines entering operation at sea to ensure that the engine design and functionality of the auxiliary systems meet our expectations, before the engine is formally introduced to our marine-engine programme, as part of a full sales release.” Fast uptake of ammonia-fuelled engines expected Thomas S. Hansen continues, “In the short term, we expect a fast uptake of ammonia-fuelled engines towards the end of the decade, as we obtain positive seagoing experience from the first engines. In the long term, we expect ammonia to comprise around 35% of fuel used onboard large merchant-marine vessels by 2050, due to lower production cost compared to other e-fuels relevant for large merchant-marine vessels.”