Hyundai Heavy Industries (HHI) - Experts & Thought Leaders

Latest Hyundai Heavy Industries (HHI) news & announcements

A landmark partnership to develop the safety guidelines for ship-to-ship ammonia bunkering has been established through a Memorandum of Understanding (MOU) between KR (Korean Register), HD Korea Shipbuilding & Offshore Engineering (HD KSOE), HD Hyundai Heavy Industries (HD HHI), KSS Line, and the Liberian Registry. Robust safety standards As the demand for ammonia-fuelled vessels rises, this partnership aims to establish robust safety standards for STS ammonia bunkering, an efficient method for supplying fuel to ammonia-fueled vessels. The safe bunkering of alternative fuels, like ammonia, requires rigorous risk assessment and the establishment of controlled zones. Ship-to-ship ammonia bunkering While standards for LNG and methanol bunkering have already been defined through various international industry standards, ammonia currently lacks relevant guidelines, highlighting the urgent need for the partnership’s research. To address this industry need, the five organisations involved will work together to develop standardised safety procedures that will set international benchmarks for ship-to-ship ammonia bunkering. Risk assessments KR will verify the compliance of these safety procedures and issue an Approval in Principle (AIP) certificate As part of the initiative, HD KSOE will perform risk assessments aligned with international industry standards, while HD HHI and KSS Line will utilise their expertise and experience in alternative-fuel vessels and ammonia carriers to evaluate controlled zones and safety procedures for ammonia STS bunkering. KR will verify the compliance of these safety procedures and issue an Approval in Principle (AIP) certificate. The Liberian Registry, overseeing the world’s largest registered fleet, will further review the validity of these safety procedures. Advancing ammonia fuel technology KIM Yeontae, Executive Vice President of KR’s technical division, commented, "With the expected rise in ammonia bunkering demand driven by the construction of more ammonia-fuelled vessels, this collaborative effort to establish safety standards is highly significant." KIM Yeontae adds, "Through this partnership, KR is committed to advancing ammonia fuel technology and supporting the industry’s decarbonisation efforts." Adoption of LNG STS bunkering KIM Jungsik, Managing Director of the Korea Office at the Liberian Registry, stated, "Just as we observed with the initial adoption of LNG STS bunkering, it is critical to establish regulations and procedures for ammonia as well." KIM Jungsik adds, "Our Innovation and Energy Transition team will thoroughly review the safety protocols and support the development of international standards."

DNV has awarded an Approval in Principle (AiP) to HD Hyundai Heavy Industries (HD HHI) for its 15K TEU ammonia dual-fuelled container vessel design. This milestone follows the successful completion of a joint development project aimed at addressing the challenges associated with using ammonia as a marine fuel. Ammonia as a marine fuel The project focused on developing cutting-edge designs to enhance safety, including an optimised ammonia tank design, advanced fire safety systems, enhanced ammonia release mitigation systems, and boil-off gas (BOG) handling systems. These innovations could play an important role in building confidence in the safe and efficient use of ammonia as a marine fuel. Safety design criteria On container ships, where the upper deck is a safe working zone, an ammonia leak could pose a serious risk Ammonia is toxic at low concentrations and corrosive, and emissions from combusted ammonia may contain a high amount of nitrous oxide (N2O), a powerful greenhouse gas. And even small leaks could potentially create a large toxic zone, endangering personnel. On container ships, where the upper deck is a safe working zone, an ammonia leak could pose a serious risk. This means, establishing safety design criteria to manage these risks is crucial for the wider commercialisation of ammonia-fueled ships. Gas dispersion analyses To this end, fuel pipe leakage scenarios were defined and quantitatively analysed through gas dispersion analyses. Consequently, it was confirmed that, with conventional systems, foreseeable small leakages occurring at connections within the ammonia piping system can form toxic areas with dangerous ammonia concentrations throughout the entire weather deck, highlighting the need for effective mitigation measures. The result showed that hazardous areas were significantly reduced by the enhanced ammonia release mitigation system, enabling not only safer enclosed spaces, but also safer working areas across the entire weather deck of the vessel. Sustainable, innovative solutions Seung-ho Jeon, SEVP, CTO of HD HHI, commented, "The AiP reflects HD HHI’s dedication to developing sustainable, innovative solutions like ammonia-fuelled vessels, which will play a key role in reducing emissions and shaping the future of shipping." Vidar Dolonen, DNV Regional Manager Korea and Japan stated, "This AiP highlights the importance of safety in moving the maritime industry along the path to decarbonisation." Zero-carbon fuels Vidar Dolonen adds, "There are many aspects to building out zero-carbon fuels in shipping, and we must have them all in place for ammonia to truly establish itself in the marine fuel market." He continues, "But with new technological solutions, alongside rigorous safety procedures, ammonia has reached its full potential as one of the most promising green fuels. DNV is proud to support these advancements from HD HHI as we continue on this journey to an even more sustainable maritime industry."

At GASTECH 2024 in Houston, KR (Korean Register) announced on September 17 that it had signed a Memorandum of Understanding (MoU) with HD Hyundai Heavy Industries (HD HHI) to develop an enhanced ammonia fuel supply system. The International Maritime Organization (IMO) has established a target to achieve net-zero greenhouse gas emissions by 2050. In line with this regulatory goal, there is a global acceleration in the development of alternative fuel technologies. Ammonia fuel supply system HD HHI will design key system configurations to integrate ammonia fuel into ammonia carriers Ammonia is emerging as a promising alternative fuel due to its sustainable advantages, including ease of storage and transportation, and avoidance of the emission of carbon and sulphur compounds. This agreement represents a collaborative effort between HD HHI and KR to advance the development of an ammonia fuel supply system. HD HHI will design key system configurations to integrate ammonia fuel into ammonia carriers. KR will conduct a comprehensive risk assessment of the system and grant an Approval in Principle (AiP). Carbon-neutral initiatives Jung Jaejun, Executive Vice President of HD HHI, remarked: "Ammonia, as a zero-carbon fuel, offers significant benefits in operational economics and supply stability. Through this risk assessment, we are dedicated to developing an enhanced ammonia fuel supply system, contributing to global carbon-neutral initiatives." Kim Yeontae, Executive Vice President of KR’s Technical Division, added: "This joint development is an important foundation for the commercialisation of ammonia-fueled vessels. KR will continue to provide essential technical support for advancing decarbonisation solutions.”

Insights & Opinions from thought leaders at Hyundai Heavy Industries (HHI)

As regulations on emissions become more stringent, more companies and organisations in the maritime industry will likely start to use methanol as a cleaner and more sustainable fuel. Methanol Methanol is a promising alternative fuel for the maritime industry due to its potential to reduce greenhouse gas emissions, increase energy security, and improve air quality. The future of methanol as a maritime fuel depends on several factors, including regulatory policies, technological advancements, and the availability and cost of methanol. Production One of the main advantages of methanol as a maritime fuel is that it can be produced from a variety of renewable and non-renewable sources, such as natural gas, coal, and biomass. Methanol can be produced using CCU technologies, which can help reduce the carbon footprint Methanol can also be produced using carbon capture and utilisation (CCU) technologies, which can help reduce the carbon footprint of the maritime industry. In addition, methanol is relatively easy to transport and store, making it an attractive option for use in marine vessels. Availability Methanol can be stored at room temperature and can be transported using existing infrastructure, such as pipelines and tankers. The availability of methanol at ports is an issue. In 2020, the Methanol Institute confirmed that methanol is already available in more than 100 ports around the globe and that 47 of those ports have storage facilities of over 50,000 metric tons. A further 66 ports are also storing methanol. Use of methanol in reducing GHGs Methanol can reduce greenhouse gas emissions and meet new emissions regulations when used as a marine fuel in various ways, including: Blending with marine diesel oil (MDO): Methanol can be blended with MDO to produce Methyl Diesel Fuel (MDF). MDF can be used in compression ignition engines that typically run on MDO or heavy fuel oil. Direct injection: Methanol can also be used as a direct injection fuel. In this case, methanol is injected into the engine’s combustion chamber and burned as the primary fuel. Methanol can be used in both spark-ignited and compression-ignited engines. Dual-fuel engines: Methanol can also be used in dual-fuel engines. In this case, methanol is injected into the combustion chamber along with another fuel, such as diesel. Diesel acts as the pilot fuel to ignite the methanol, which is burned as the primary fuel. Pros and cons Methanol is highly toxic and flammable, so it requires careful handling and storage to ensure safety One advantage of using methanol as a maritime fuel is that it has a high-octane rating, which can improve engine performance. Methanol is also relatively easy to produce, and it can be made from renewable sources such as biomass. However, methanol is highly toxic and flammable, so it requires careful handling and storage to ensure safety. Environmental benefits Methanol has several environmental advantages over traditional maritime fuels such as heavy fuel oil and marine diesel oil. These advantages include: Lower greenhouse gas emissions: Methanol has a lower carbon content than traditional maritime fuels, which means it produces fewer greenhouse gas emissions when burned. Methanol can reduce greenhouse gas emissions by up to 15% compared to traditional fuels. Reduced air pollution: Methanol also produces fewer emissions of harmful air pollutants such as nitrogen oxides (NOx) and particulate matter (PM) when burned. Methanol can reduce NOx emissions by up to 60% and PM emissions by up to 95% compared to traditional fuels. Biodegradability: Methanol is biodegradable, which means it can break down naturally in the environment. This is important in case of any accidental spills or leaks that may occur during fuel handling and transportation. Renewable source: Methanol can be produced from renewable sources such as biomass, which means it can be a sustainable alternative to traditional maritime fuels. Energy efficiency: Methanol has a high energy content per unit of weight, which means it can provide more energy per unit of fuel compared to traditional fuels. This can lead to improved energy efficiency and lower fuel consumption. Maritime applications Stena Line has converted one of its ferries, the Stena Germanica, to run on methanol Overall, using methanol as a maritime fuel can help reduce the shipping industry's environmental impact and promote more sustainable and responsible practices. Several companies and organisations have started using methanol for maritime applications. Stena Line, a Swedish ferry operator, has converted one of its ferries, the Stena Germanica, to run on methanol. The ferry operates between Kiel, Germany, and Gothenburg, Sweden. Nominal capacity In addition, Maersk Line, the world's largest container shipping company, has announced plans to use methanol as a marine fuel. In October 2022, Maersk announced it has ordered a further six large ocean-going vessels that can sail on green methanol. The six vessels will be built by Hyundai Heavy Industries (HHI) and have a nominal capacity of approximately 17,000 containers (Twenty Foot Equivalent - TEU). They will replace the existing capacity in the Maersk fleet. With the order, Maersk has in total ordered 19 vessels with dual-fuel engines able to operate on green methanol. Methanol engines MAN Energy Solutions, a provider of marine engines, has developed methanol engines for use in maritime applications. The engines can be used in both propulsion and auxiliary power applications. Methanol-based two- and four-stroke solutions will be relevant for the complete MAN Energy Solutions marine engine portfolio. Typical examples of the application of four-stroke engines include container ships, ferries, fishing or cruise vessels, as well as offshore solutions. Future adoption Adoption of methanol will depend on cost, availability, and the development of regulatory frameworks Stationary solutions might also be a possible area for methanol applications, for example, for small islands that lack natural gas infrastructure. However, the wider adoption of methanol as a maritime fuel will depend on several factors, including the cost of methanol production, the availability of methanol infrastructure, and the development of regulatory frameworks to support its use. Nevertheless, the future of methanol as a maritime fuel looks promising, as it offers a potential solution to the maritime industry's environmental and energy security challenges. Flexible in use Battery electric propulsion is another potential alternative to traditional maritime fuels, but it is limited by the current state of battery technology, which makes it difficult to achieve long-distance, large-scale shipping operations. Methanol can offer a longer range and greater flexibility than battery electric propulsion while still reducing emissions. Overall, while methanol is not a perfect solution, it offers several advantages over other maritime fuels and has the potential to play a significant role in reducing the environmental impact of the shipping industry.

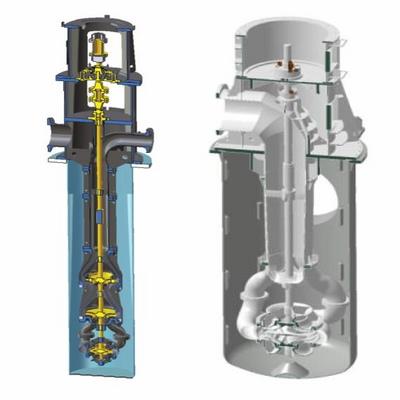

Hyundai Heavy Industries XCAF Cable Free Submersible Pump

Hyundai Heavy Industries VWDB Vertical Multi Stage Pump

Hyundai Heavy Industries VK / VA Vertical Single Stage Pump