Damen Marine Services BV - Experts & Thought Leaders

Latest Damen Marine Services BV news & announcements

Damen Marine Components (DMC) has been contracted to supply rudder systems for four Pure Car and Truck Carriers (PCTC), each capable of carrying up to 9,200 CEU (car equivalent units). The vessels are being built at China Merchants Jinling Shipyard (Jiangsu) Co., Ltd and China Merchants Heavy Industry (Jiangsu) Co., Ltd for their client BYD Auto, China’s largest manufacturer of electric and hybrid vehicles. When launched, the PCTCs will be the largest of their class in the world. Asymmetric Rudder Technology For each PCTC, DMC will be supplying an Atlantic Rudder with Asymmetric Rudder Technology (ART™) and a Silent Bulb. With no moving parts, these spade rudders are highly dependable and with a slim profile offer minimal resistance. Their excellent course-keeping capabilities make them a popular choice for long-distance, ocean-going vessels. Each rudder is custom-built to take account of the hull shape and the propeller angles of the vessel on which it will be installed. Optimised in this way, the asymmetric pioneering edge (ART™) smooths the water flow over the rudder to maximum effect, reducing resistance cavitation, and fuel consumption. ‘Silent Bulb’ The dual approach not only prolongs the rudder’s lifespan but also amplifies the maximum propeller thrust The customer has also opted to have a DMC Silent Bulb mounted on each rudder. This energy-saving device minimises the likelihood of cavitation around the rudder by mitigating the inevitable flow losses caused by the propeller. This dual approach not only prolongs the rudder’s lifespan but also amplifies the maximum propeller thrust, thanks to the significantly enhanced propeller efficiency. Top quality, low maintenance “We selected Damen Marine Components for the rudder systems as they have a long track record for developing and building top quality, low maintenance steering equipment,” says Mr. Fei Li, Purchasing Director of China Merchants Jinling Shipyard. Fei Li adds, “As a pioneering manufacturer of low-emissions vehicles and one that exports all over the world, the reliability of its PCTCs is vital to BYD Autos’ operations.” Mission-critical equipment “We are very pleased that China Merchants Jinling Shipyard has come to us for this mission-critical equipment,” says Bogdan Mocanu, Area Sales Manager at DMC. Bogdan Mocanu adds, “We value their endorsement of our products and are confident that our rudders will give many years of economical and trouble-free operations.” China Merchants Jinling Shipyard China Merchants Jinling Shipyard is a shipbuilding company located in Nanjing, Jiangsu province, China. Established in 1951, it has grown to become one of the largest shipyards in China. The shipyard specialises in constructing various types of vessels, including the Airbus 380 Roro vessel, Ropax, PCTC, bulk carriers, container ships, MPV, and LNG carriers. The shipyard employs over 10,000 people and has a production capacity of up to two million deadweight tonnes per year. The first vessel is scheduled for delivery in 2025.

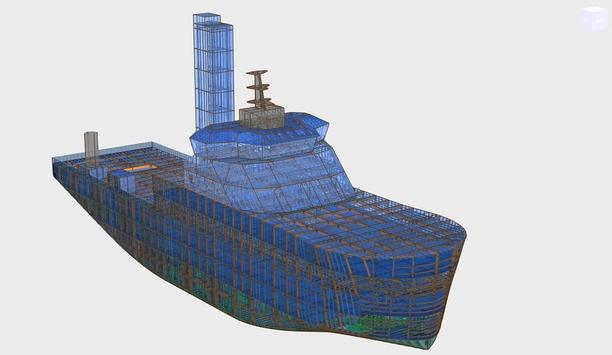

Damen, DNV, and NAPA are taking a major step forward in ship design processes by using the new Open Class 3D Exchange (OCX) standard to streamline classification involvement in the early phase of a project. 3D model exchange and approval With increasing pressure to deliver vessel designs quickly, the early engagement of classification societies can increase designer and owner confidence in the concept design and ensure smooth project execution. Responding to market expectations, Damen Engineering decided to involve DNV classification experts in the first review of its new design of a Commissioning Service Operation “Walk to Work” Vessel (CSOV 9020). The collaboration started during work on the Design Proposal, the very first stage of the project, using new cutting-edge technology based on 3D model exchange and approval through the OCX file format. CSOV design The new CSOV design was developed by Damen engineers using NAPA’s 3D design tools The new CSOV design was developed by Damen engineers using NAPA’s 3D design tools, which enable the export of 3D models in the OCX format. This functionality allowed Damen and DNV to work in parallel on the same 3D model, saving the time and effort needed to agree on and prepare 2D documentation. Beneficial approach Katarzyna Romantowska-Jaskólska, Managing Director at Damen Engineering, said, “Environmental, safety, regulatory and other external pressures, combined with the competitive need to create ever-better designs, mean doing things the way we always did them is no longer sufficient." Katarzyna Romantowska-Jaskólska adds, "The OCX format allows us to take a new approach that is beneficial to everyone involved in the development of a vessel design, and the project execution process. In collaboration with DNV and NAPA, we arrived at a solution that connects disciplines and facilitates quick decision-making while reducing risks in the early stages of a design.” 3D design solutions NAPA’s 3D design solutions can support efficient information exchange between ship designers and classification societies" Mikko Forss, Executive Vice President for Design Solutions at NAPA, added, “At NAPA, streamlining the hull structure approval process through efficient collaboration and swift feedback loops among stakeholders is one of our top priorities. As a result of several joint industry development projects, NAPA’s 3D design solutions can support efficient information exchange between ship designers and classification societies, enabling quicker and more accurate approvals." Mikko Forss adds, "Our support for the OCX format is a key part of this effort, as it enables the standardised exchange of 3D model data and reduces the time and effort required for efficient communication.” Interact and cooperate in early design Ivar Håberg, Director of Approval at DNV, concluded, “The earlier class starts the design approval process, the easier it is to find good rule-compliant design solutions in cooperation with the yards. By using the OCX file format to exchange information on 3D design models, DNV can more efficiently interact and cooperate with the designers and yards already in the early design development phase.” OCX 3D model OCX is a new standard for 3D model-based class approval, aimed at breaking down the barriers between different design and classification software platforms to enable the seamless exchange of idealised geometry and metadata between them. The OCX 3D model can also replace the traditional 2D structure drawings for classification purposes, thereby saving time for the yards, and allowing the class to respond more quickly to designers' needs. OCX Consortium The OCX standard is the result of the joint industry project ‘Approved (2016-2020)’ headed by DNV. The standard is jointly owned and managed by the OCX Consortium established in 2021. This consortium has brought together more than 30 industry leaders to jointly promote and maintain the standard. The consortium members consist of all the major classification societies, leading CAD providers, and several designers and yards.

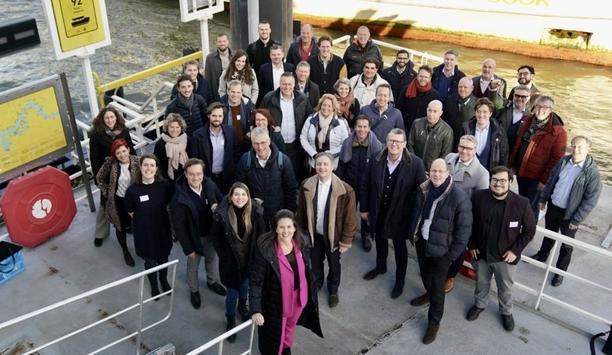

The PortXL community gathered at the RDM Innovation Dock to celebrate the achievements of the 2022 cohort. The solutions of the 13 start-up companies vary from flywheel designs originally meant for space operations to offshore wind turbine floaters that double as hydrogen storage. The goal of the PortXL acceleration programme is to build collaborations between corporates and start- and scale-ups to accelerate innovation. More than 10 collaborations were signed to continue working with these innovators and more to come in the following months. Highlighting future collaborations Representatives from the Port of Rotterdam Authority, Van Oord, Gemeente Rotterdam, Shell, Damen, Boskalis, Ampelmann, InnovationQuarter, Deltares, SPEED, and Provincie Zuid-Holland joined to sign collaborations. What an exciting ride it has been. I’m really proud of the achievements that have been presented" Hedi Visscher, Director PortXL: “What an exciting ride it has been. I’m really proud of the achievements that have been presented. The development curve of all the companies has consistently grown and together with our partners in the maritime industry collaborations have been signed.” Surrounding marine environment The 13 companies that participated: CleanSubSea, Australia: Their Envirocart™ System enables the in-water removal, capture, containment and filtration of marine biofouling from a vessel’s hull without damaging the antifouling paint or polluting the surrounding marine environment. No fuel or time is wasted driving to a dry dock location. QuinteQ, Netherlands: Flywheel energy storage technology based on Boeing developments that realises up to a fifteen-fold improvement on energy storage, applicable in energy systems and grids worldwide, and returning more than 50 financial returns to investors. They use advanced materials with high tensile strength to allow them to experience energy density improvements that far outpace breakthroughs in battery technologies. Ensemble Analytics, UK: Platform for ports that assimilates data and produces detailed advice for real time decision making on workforce allocation, training and investment. Efficient decision making can turn vessels around 8% faster, reducing emissions in port and improving local air quality. Conexbird, Finland: Vibration analysis hardware, supported by a software component, designed for mounting on container spreaders, and able to withstand the harsh conditions spreaders are subjected to. Mathclick, Italy: AI based solutions to interpret and forecast aquatic data. Finsulate, Netherlands: Revolutionary antifouling product, no paint needed. Instead, an environmentally-friendly physical adhesive barrier is applied to the hull with a 5 year expected lifetime. Skygauge, Canada: The most stable drone users will ever see, with patented thrust-vectoring technology. Perfect for safe industrial inspections and ultrasonic testing. Psiori, Germany: Creates Crane AI, which provides 3D scans of the inventory and environment and cameras detecting the position of the load. Their technology allows the crane operator to avoid mistakes or train for special occurrences. DecisionHall, Netherlands: Assembles a corporation of stakeholders with global reach who employ the latest Digital Engineering techniques to significantly reduce the risk, cost, and time required to run complex sustainability and climate resilience projects. Rombit Studio, Belgium: Co-creates innovative and sustainable digital products which create value and increase efficiency for their customers. By applying digitalisation and predictive analytics technology, the company connects devices and platforms to existing infrastructure. Noble Gas Systems, United Stated: Focuses on developing safe and lightweight compressed gas storage systems. Recently, the company demonstrated its latest generation of conformable gas tanks, which can be configured into existing vehicle architectures. MayMaan, United States: Creates engine technology that is fueled by 70% water and 30% ethanol. Their technology is designed to systematically decrease operational costs and significantly reduce the carbon footprint. GBMS, Netherlands: Focuses on developing systems that can reduce the number of containers lost at sea. They develop warning systems by understanding ship motions, physics, software, and sensor technology development. 12toZero, Netherlands: Developing a unique floating wind foundation specifically designed to combine buoyancy and hydrogen storage in a single structure. The combination of these functions in a single platform provides that basis for a reliable hydrogen supply for the decarbonisation of marine applications and port-based industries.