Swiss marine power company - WinGD has received its hundredth order for Variable Compression Ratio (VCR) technology, which further optimises combustion for X-DF dual-fuel engines depending on the fuel used and engine load.

The innovative solution was launched in June 2023 and has already become a favoured option for dual-fuel engine orders, especially in the LNG carrier segment.

LNG carrier segment

The milestone order came via a series of four LNG carriers to be built for a Middle Eastern shipowner at a Korean shipyard. These join several other orders that have made X-DF engines and VCR technology the standard choice for the LNG carrier segment over the past year, with further orders coming from the pure car and truck carrier, bulk carrier and container ship segments. Overall, nearly 10 owners have selected the new technology as an option with their X-DF engines.

WinGD Director Sales, Volkmar Galke, said: "Surpassing a hundred orders for our variable compression technology called VCR in the first year is a phenomenal achievement and indicates the strong market interest in technologies that can both reduce the environmental impact of gas-fuelled engines and eliminate any compromise in diesel performance. We’re grateful to those early adopters and see even greater opportunities for the industry to benefit from this unique engine technology in the future.”

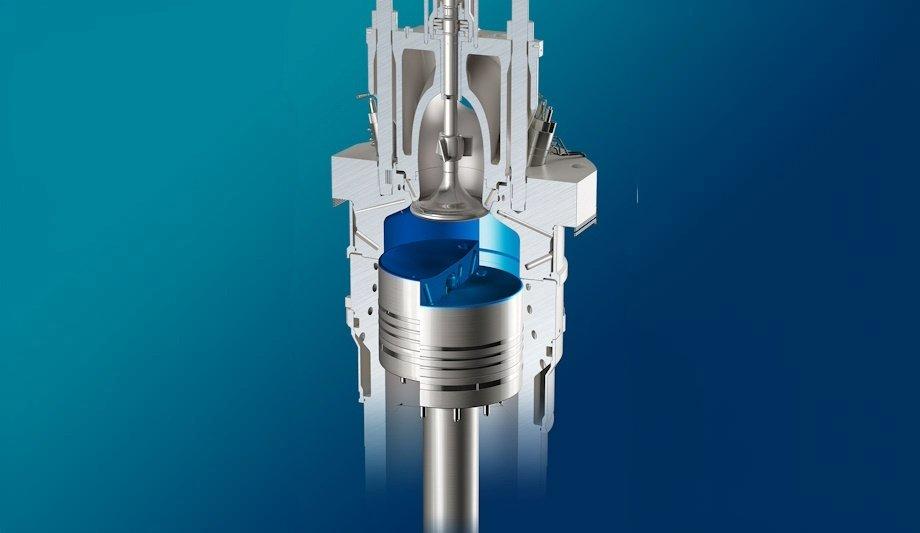

Simple hydraulic solution

VCR technology enables the engine’s compression ratio to be dynamically adjusted for the fuel type being used

VCR technology enables the engine’s compression ratio to be dynamically adjusted for the fuel type being used, engine load and combustion behaviour.

This means higher compression ratios can be used when running on diesel, improving efficiency, while compression can also be tweaked during LNG use to optimise efficiency and reduce emissions. The simple hydraulic solution represents the first application of dynamic compression ratio adjustment in a marine engine.

X-DF engines with iCER and VCR

VCR is the second X‑DF2.0 technology introduced by WinGD as an enhancement to its well-established X‑DF dual-fuel engine platform. The first addition, Intelligent Control by Exhaust Recycling (iCER), has also been well received and has been deployed on most orders for LNG carriers over the past two years.

In recent tests, WinGD has established that X-DF engines with iCER and VCR achieve lower fuel consumption and emissions than rival low-pressure engine technologies.

Fuel consumption and emissions

Compared on a system-level, including main and auxiliary engines as well as fuel supply, vessels can achieve a similar fuel consumption and emissions profile as those powered by high-pressure, diesel cycle two-stroke engines, while maintaining a capex advantage due to the low cost of the auxiliary system required.

The new technology, combined with a reliable in-service record of more than 7.5 million running hours for the X-DF engine platform, make X-DF engines the clear market choice for the LNG carrier segment and competitive against high-pressure engines in other vessel segments.