The International Maritime Organization’s (IMO) decision to ambitiously cut greenhouse gas (GHG) emissions in half by 2050 is at the top of shipping companies’ agendas. To ensure that ships contribute as little as possible to GHG emissions, all stakeholders must use cutting-edge technology.

This offers a closer look at the technologies that are available for regulatory compliance and energy efficiency improvement.

Air Lubrication System

The air lubrication system creates a carpet of micro-bubbles that coats the vessel’s entire flat bottom. This carpet effectively reduces the frictional resistance between the hull and the water.

The technology, applied in all maritime conditions, is not weather dependent and has no constraints or negative impacts on the vessel’s normal operational profile.

Rotor sails

Rotor sails (Flettner rotors) use the wind to further improve ship fuel efficiency

Rotor sails (Flettner rotors) use the wind to further improve ship fuel efficiency. When the wind conditions are favourable, the rotor sails allow the main engines to be throttled back, saving fuel and lowering emissions while maintaining speed and voyage time.

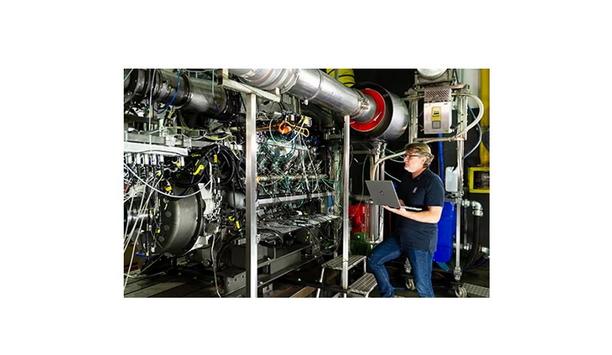

Shaft Generator Solution

Both the air lubrication system and the rotor sails consume electricity when they are running. The shaft generator, with the highest power efficiency and lowest operating costs, is one of the most cost-effective measures to generate electricity onboard. It is an ideal solution for ship owners, in terms of lower operational costs, reduced carbon footprint, and regulatory compliance.

The shaft generator, driven by the main engine at a variable speed, generates the electricity onboard. Therefore there is a significant reduction in the auxiliary generator’s running hours, which minimises fuel consumption.

With WE Tech’s shaft generator solution, the following targets are achievable:

- 25% CO2 savings per vessel is achievable due to decreased fuel demand.

- Because of the minimised running hours of auxiliary engines, there is the possibility to use low or even zero-emission fuels for the main engine only.

- In addition to reducing the environmental footprint, 35% and beyond of energy efficiency improvements can be achieved.

- The vessel’s system reliability and flexibility can be significantly improved.

- The significantly lower operational costs short the payback time to 2-4 years.

- Complete adherence to environmental regulations. The increased efficiency in propulsion machinery, power generation and distribution can further reduce emissions.

Baseline solution to meet IMO’s EEDI and CII for newbuilds

Because of its positive economic and environmental impact on vessels, the shaft generator is rapidly becoming the baseline solution to meet IMO’s EEDI and CII for newbuilds. It is also one of the key means for current vessels to improve their efficiency rating on the IMO’s EEXI.

Over 120 vessels sailing currently are benefiting from WE Tech’s shaft generator solution. Whether new builds or retrofits, WE Tech always has a solution for the pathway towards zero-emission!