The frequency of container losses at sea has been a problematic and very costly issue for the industry over the years. According to the World Shipping Council 2019 report, there is an average of 1,382 containers lost at sea yearly.

Whilst these figures are small in comparison to the number of containers being transported annually, container stack collapses still pose a significant risk to the industry, both in terms of claims and potential environmental impacts.

Potential environmental impacts

Even though there have been advances in the procedures and standards for the loading, securing, and carriage of containers, stack collapses are still happening with each winter season raising the prospect of more to come.

A collapse of on-deck container stacks poses a serious threat to the safety of the crew and the ship

A collapse of on-deck container stacks poses a serious threat to the safety of the crew and the ship. It can also have significant impacts on the environment, depending on the container contents, with clean-up and recovery costs significantly increasing the value of claims and the associated impacts on reputations. The question of what causes a stack collapse, how can they prevent it, or what to do when there is a collapse, is the subject of ongoing research and consideration by experts within the industry.

Parametric and synchronous rolling

There are a number of factors that may cause a collapse, including: the design of the vessel, its speed and heading, its stability characteristics, the sea conditions, the stowage, securing methods and equipment, and the phenomena known as parametric and synchronous rolling.

In adverse weather conditions, vessels can encounter excessive rolling and pitching which can cause a ship to roll at extreme angles of up to 30 degrees or more, potentially leading to a stack collapse and the loss of containers. When this occurs, swift action must be taken. A simple adjustment in the speed and course of the vessel may be enough to remedy the situation or prevent a dangerous incident. However, having the right information to hand when such situations arise is critical.

Safer operating condition

This information can be printed and placed on the bridge as an easy-to-use support tool

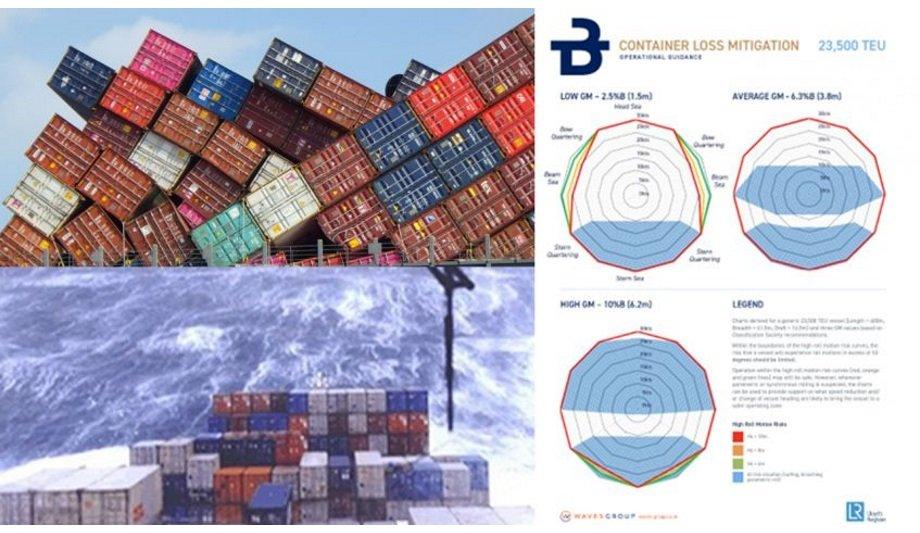

Waves Group has worked with the Britannia P&I Club and Lloyd’s Register to develop simple on-board guidance to assist the bridge team in identifying conditions that may lead to parametric or synchronous rolling and how to take the appropriate actions to mitigate these risks.

The operational guidance is available here and can also be found on the Britannia P&I Club’s website. It covers container vessels from 3,000 up to 23,000 TEU in size. This information can be printed and placed on the bridge as an easy-to-use support tool to determine what change in the vessel’s speed and heading may be required to bring it to a safer operating condition.

This guidance applies to their collective experience of containership operations and the investigation of numerous stack collapses. They are pleased to have partnered with Britannia P&I Club and Lloyd’s Register to provide a valuable solution, that will assist vessel operators to mitigate the risk of container losses and major incidents.