Tsuneishi Shipbuilding Co., Ltd. has signed the latest contract for MAN Energy Solutions’ dual-fuel, methanol-powered MAN B&W ME-LGIM engine.

Long-term MAN Energy Solutions licensee, Mitsui E&S Machinery, has won another contract to supply the individual MAN B&W 6G50ME-LGIM (-Liquid Gas Injection Methanol) engine for a 65,700 dwt bulk carrier slated for construction at Tsuneishi Shipbuilding Co., Ltd. The vessel represents the latest methanol-fuelled engine ordered by the bulk-carrier segment in recent weeks.

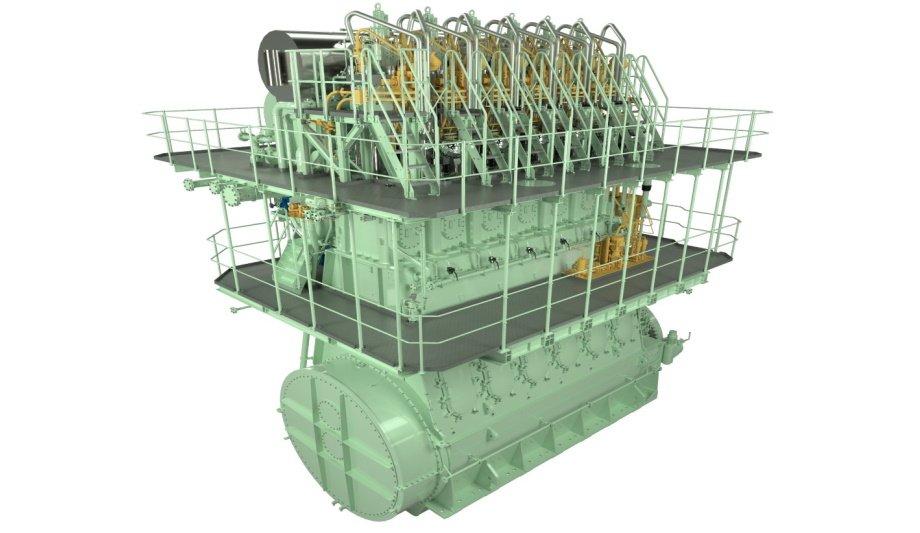

Dual-fuel MAN B&W ME-LGIM engine

We will continue to focus on technological innovation together with engine manufacturers"

Sachio Okumura, the Representative Director and President & Executive Officer of Tsuneishi Shipbuilding, said: “For TSUNEISHI SHIPBUILDING, which is striving to build methanol-fuelled ships with the aim of becoming a front-runner in next-generation-fuelled ships, securing a high-value-added engine through this contract is an extremely important step.”

Sachio Okumura adds, “We will continue to focus on technological innovation together with engine manufacturers, in order to provide our customers with zero-emission ships that are both environmentally friendly and economical.”

Broad interest in next-generation fuels, such as methanol

Ichiro Tanaka, the President and Representative Director of Mitsui E&S Machinery, said: “Customers are increasingly interested in next-generation fuels, and methanol is one of the promising fuels. We have a track record of manufacturing dual-fuel engines such as LNG-fired engines, and in 2015, we delivered the world's first methanol engine as the main engine for a methanol carrier.”

Ichiro Tanaka adds, “Taking advantage of this adoption for bulk carriers, we will continue to meet the various needs of our customers, provide engines that are environmentally friendly and economical, and contribute to the realisation of a decarbonised society.”

Rise in global demand for decarbonised transport

Bjarne Foldager, the Senior Vice President and Head of Low-Speed, MAN Energy Solutions, said: “In a market that has seen a rapidly increasing demand for decarbonised transport from its major players, the interest in methanol as a fuel has surged and – at this moment in time – represents more than 30% of all our current, open pipeline projects across a broad range of vessel segments.”

Bjarne Foldager adds, “As such, seeing bulk carriers now also entering this fuel segment is completely in line with our expectations and these newbuildings will benefit greatly from the option to operate either on methanol or conventional fuel with equally high fuel efficiency.”

Methanol can be carbon-neutral fuel

As a fuel, methanol can be carbon-neutral when produced from renewable energy sources and bio-genic CO2

As a fuel, methanol can be carbon-neutral when produced from renewable energy sources and bio-genic CO2. The production capacity of such green methanol is currently increasing significantly; it is also liquid at ambient conditions, which simplifies tank design and minimises costs.

MAN Energy Solutions reports that its methanol engine requires a fuel-supply pressure of just 13 bar and that a number of manufacturers already offer such fuel-supply systems currently.

Wide adoption of low-emission engines

Peter Quaade, the Head of Dual-Fuel Engine Group – Two-Stroke Operations – MAN Energy Solutions, said: “With more than 20 engines installed in vessels already on the water and in excess of 200,000 operational hours on methanol since the first such engine entered service in 2016, provides an already proven and mature technology.”

Peter Quaade adds, “In adopting these low-emission engines, Tsuneishi Shipbuilding once again demonstrates its commitment to providing advanced solutions for the benefit of both vessel owners and the environment.”

About the MAN B&W ME-LGIM engine

MAN Energy Solutions developed the ME-LGIM dual-fuel engine for operation on methanol, as well as conventional fuel. The engine is based on the company’s proven ME-series, with its approximately 8,500 engines in service, and works according to the Diesel principle. When operating on green methanol, the engine offers carbon-neutral propulsion for large merchant-marine vessels.

MAN developed the ME-LGI engine in response to interest from the shipping world in operating on alternatives to fuel oil in order to reach decarbonisation targets. Methanol carriers have already operated at sea for many years using the engine, and, as such, the ME-LGIM has a proven track record offering great reliability and high fuel-efficiency.