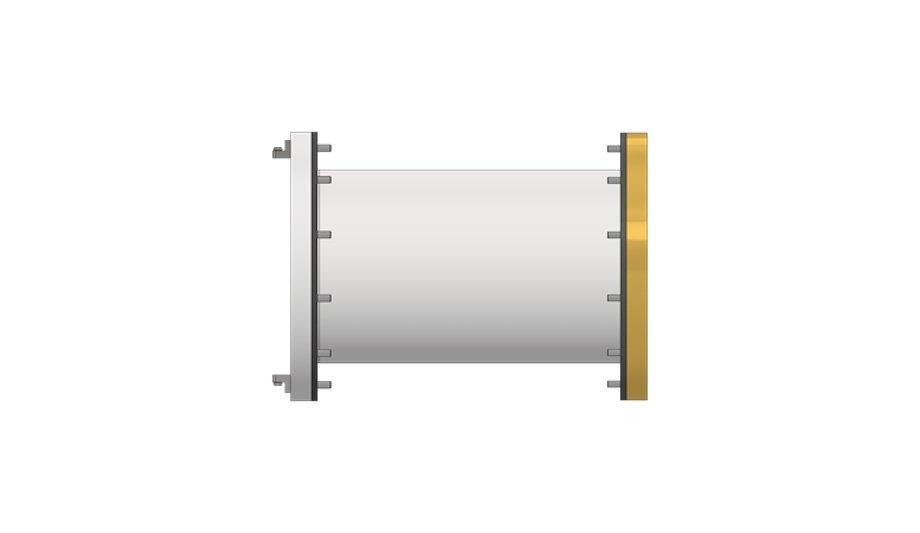

Technology group Wärtsilä introduces EvoTube, a revolutionary and patented advancement in Shaft Line technology for marine propulsion systems, reducing risk and simplifying operations. While based on a conventional stern tube, the EvoTube is a significantly simplified system with fewer components than a conventional stern tube system.

The inboard seal is mounted directly on the aft bearing housing, and the forward bearing is replaced with a standalone bearing inside the engine room. Its intelligent design optimises space utilisation and eases maintenance tasks.

EvoTube concept

EvoTube shows our dedication to advancing the maritime industry with innovative solutions"

The EvoTube concept is suitable for both oil and water lubrication systems, also facilitating future conversion from oil to water lubrication systems, effectively environmentally future-proofing vessels anytime during the vessel’s operational life.

“EvoTube is a game-changer in marine propulsion. Wärtsilä offers shipowners and operators an environmentally future-proof option of seamless transition from oil to water. EvoTube shows our dedication to advancing the maritime industry with innovative solutions that simplify operations, while minimising environmental impact," says Rob Burford, VP Wärtsilä Shaft Line Solutions.

EvoTube advancements

With a remarkable 90% reduction in required oil volume for stern tube lubrication, EvoTube enhances efficiency and reduces operational costs.

The system's advancements, including eliminating shaft corrosion in water lubrication, present a low-risk solution for shipyards and designers, streamlining the design process and contributing to overall operational efficiency.

EvoTube benefits for owners/operators

General

- Suitable for oil & water lube systems.

- Simplified system–no forward stern tube bearing means less that can go wrong & less maintenance.

- Low risk, based on existing technology.

- Frees up valuable cargo space.

- Easier future modification from oil to water lubrication.

- Permits easier maintenance of equipment onboard.

Oil lubrication

- Stern tube lubrication oil was reduced by ~90%.

- Improved through-life quality of the stern tube oil due to simplified oil maintenance during operation.

- Simplified oil management during maintenance of the stern tube seals.

- Can be modified from oil lubrication to water lubrication.

Water lubrication

- Eliminates shaft corrosion – no shaft coatings are required as for conventional water-lubricated stern tubes.

- Enables full in-water serviceability including aft bearing replacement.

- Compact design frees up valuable cargo space and permits easier maintenance of equipment onboard.

Wärtsilä Shaft Line Solutions

Wärtsilä Shaft Line Solutions represents a cutting-edge approach to revolutionising marine propulsion systems. Commitment to technical excellence is evident in state-of-the-art solutions, designed to enhance operational efficiency, minimise risks, and contribute to a more sustainable maritime future.