Eneco have ordered a 12 MW High Voltage Electrode Boiler from PARAT Halvorsen. The requirement is for a hot water boiler with 23 kV voltage, 6 barg operating pressure and 110°C operating temperature.

The Electrode boiler will be installed in Eneco’s district heating facility in Ypenburg, and will replace a Gas-Fired boiler to reduce emissions and now give the option to do grid regulation.

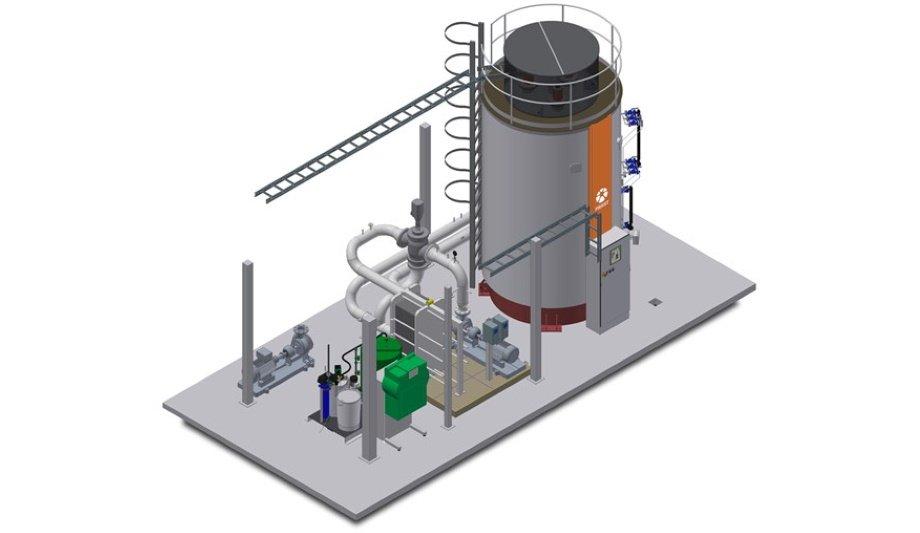

PARAT Electrode boiler

PARAT will supply and produce the boiler with control panel, skid with circulation pump and heat exchanger, as well as supply the circulation line, a skid with water treatment, RO plant, softening filter and dosing system.

Both skids are pre-fabricated with pipes, cables and electrical components pre-assembled at PARAT Halvorsen. The skids will be dismantled before transport and assembled in Eneco’s boiler house by PARAT personnel. In addition, PARAT will supply the secondary pump and control valves for Eneco to install. Start-up of the boiler is scheduled for early 2020.

Residual heat produced from gas boilers

In the Ypenburg district of The Hague, houses and offices are heated with district heating

In the Ypenburg district of The Hague, houses and offices are heated with district heating. This is residual heat from electricity production and heat from gas boilers. This electricity and heat are made with fossil natural gas, which releases CO2. Eneco wants to reduce CO2 emissions and is therefore, constantly looking for new solutions.

With an electrode boiler, Eneco wants to partially electrify heat production for the Ypenburg district heating network, as an alternative to gas-fired heat. In addition, the electrode boiler offers a new solution to match demand and supply on the electricity grid.

Installation at Ypenburg co-generation plant

This coordination is becoming increasingly important, as more and more energy is generated with sun and wind. The introduction of the electrode boiler at the Ypenburg co-generation plant on this scale is new for the Netherlands and is a pilot project for Eneco to investigate the application.

The cogeneration plant (WKC) Ypenburg produces district heating for the Ypenburg district. The plant consists of six gas engines (CHPs) that produce electricity and residual heat, three gas boilers that produce heat, and two gas boilers that ensure that sufficient heat can be supplied in the winter.

In the plant, one of the gas boilers (5.4 MWth) is replaced by the electrode boiler (12 MWth). The electrode boiler is used for the production of heat.

Electrode boilers, key to sustainable energy switch

The use of an electrode boiler on this scale is new for the Netherlands. Electrode boilers are important for the switch to a fully sustainable energy supply. The project is a pilot project and the experience gained from this is important for the future role of this technology, for the production of district heating and for the electrification of heat and steam generation for the industry.

The development of these forms of conversion and storage capacity is a crucial step in the energy transition and contributes to reducing gas consumption, and related CO2 emissions.

How does an electrode boiler work?

An electrode boiler converts electricity into heat and is one of the so-called ‘power-to-heat’ techniques

An electrode boiler converts electricity into heat and is, therefore, one of the so-called ‘power-to-heat’ techniques. The electrode boiler is a large pressure vessel with a diameter of almost 3 metres and a height of 6 metres. The vessel is partially filled with water that is being pumped around. An insulated container hangs in the vessel, into which the water flows and comes into contact with the electrodes that are under high voltage.

The water heats up quickly due to contact with the electrodes. The heated water flows from the insulated container to the large vessel, and is then passed along a heat exchanger. This ensures that the heat is transferred to the district heating network. This city heat can then either be stored in a heat buffer or go directly to the Ypenburg district, to heat the connected houses and offices.

Sustainable future energy source

The higher the water level in the insulated container, the greater the contact surface with the electrodes. The larger the contact surface, the more electricity is used more hot water is produced. Because the water level in the tank can be adjusted quickly, the electrode boiler can quickly arrange for the supply and demand of electricity on the electricity grid.

This coordination is becoming increasingly important because more and more energy is generated with sun and wind. The electrode boiler thus ensures a balance on the electricity grid and also for the production of city heat.