Shabnum Hanif, Ocean Infinity’s Offshore Business Line Director discusses how Digital Twin technology can enhance offshore Inspection, Maintenance and Repair (IMR). It’s become commonplace to see more and more digital visualisation tools being used in many industries.

The term Artificial Intelligence (AI) itself is almost used in the vocabulary, as much as ‘milk and two sugars’. Thinking about all these newly available technologies (from robot dogs to driverless cars), frankly implores the question, have we really become that digital and what does this mean for subsea operations?

Digital Twin technology

The use of Digital Twin technology further reduces maintenance and operating costs

The offshore industry is increasingly using Digital Twin technology, to sustainably enhance efficiency, safety, and to support the extension of asset life expectancy. Any asset, be it renewables, oil and gas or, any type of critical infrastructure (tunnels, damns, etc.), can be digitally depicted.

Inadvertently, the use of Digital Twin technology further reduces maintenance and operating costs. This can only be a bonus.

‘Digital Twin’ helps optimise business value

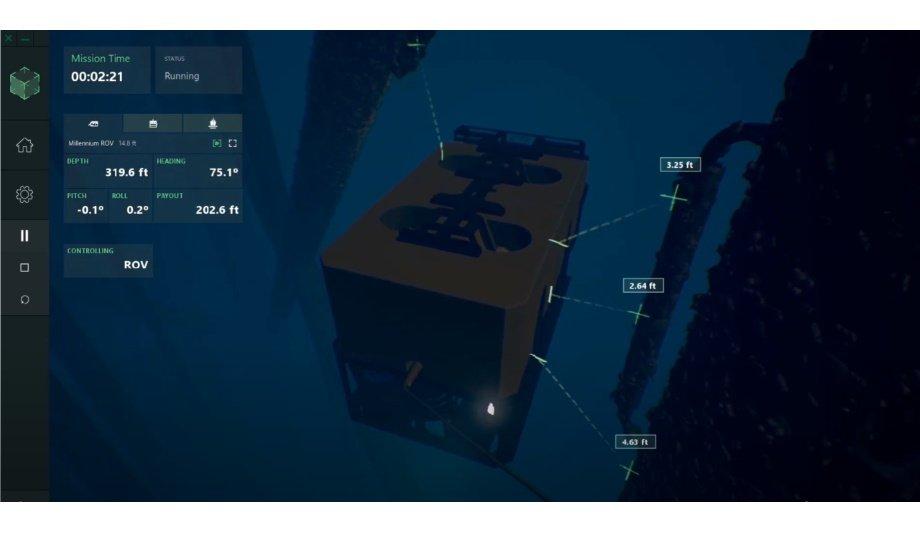

A Digital Twin delivers a digital representation of a physical asset, system or process, designed to detect, prevent and predict analytics, in order to optimise business value. This real-time virtual representation of physical assets and its behaviour, delivers a shorter response time, therefore, allowing operators to obtain greater insights, so as to better enhance Inspection, Maintenance and Repair (IMR).

Ocean Infinity’s Digital Twin solution can be used throughout the entire project life cycle. From design and engineering, construction, operations, through to decommission stages.

Next-gen data visualisation

With extensive expertise in the 3D visualisation, simulation and digital twinning of offshore assets, Ocean Infinity provides the next-generation data visualisation and interface, to support the planning and execution of offshore operations, and to process, contextualise and deliver the acquired data.

The solution combines an ecosystem of applications that can work both independently and simultaneously, to provide value-added benefits in every phase of a project and deliver a true digital asset life cycle management.

Platform offers holistic view of all marine operations

All applications are connected and can continuously provide new data and insights

Spanning offshore management of subsea and top-side operations to remote onshore monitoring, this platform accomplishes a holistic view of all marine operations. All applications are connected and can continuously provide new data and insights, to allow the end user to have the most up-to-date version of the reality.

Additionally, the platform can also be connected to different third-party systems, such as ERPs, GIS DBs, and documentation systems, to provide one single view of assets and operations. All data is maintained and securely accessible through the life of the field and across all applications.

Optimised fleet robotics

Creating a virtual digital replica of the entire environment, collecting video, telemetry, positioning, and other sensor data (laser scan, MBES, sonar, geo-locate imagery and video), during the operation, as well as processing and streaming the information onshore, to command centres via secured cloud access, allows for a complete traffic, operations, and data management control system for multiple autonomous and remote vehicles.

The Ocean Infinity Digital Twin solution is a key enabler to allow the usage of crewed and uncrewed vessels, Remote Operated Vehicles (ROVs) and Autonomous Underwater Vehicles (AUVs) for inspection and environmental monitoring operations, such as monitoring sand wave migration across the site, scour growth at the foundations, the positions and condition of the cable, and the cable protection system, as well as the condition of the jacket structure.

Digitalising assets and subsea structures

By enabling the creation of a Digital Twin, even before construction starts, this spatial computing platform not only increases profitability of field development in inaccessible areas, but also increases production efficiency of operations.

Simply put, digitalising assets and subsea structures truly optimises offshore operations. Given the added benefits of using digitalised platforms onshore to assess and assist with offshore operations, it’s no wonder the world has gone AI mad.