Dalian Shipbuilding Industry Co. Ltd. has ordered 2 × MAN B&W 7S35ME-GI dual-fuel engines in connection with the construction of two 7,500 cubic-metre, liquid CO2 carriers for Northern Lights, the joint venture between Equinor, Shell and TotalEnergies.

Each ME-GI engine will feature MAN Energy Solutions’ proprietary EcoEGR (Exhaust Gas Recirculation) system. Delivery of the 130-metre carriers has been set for mid-2024.

Carbon-capture-and-storage (CCS) project

Northern Lights is responsible for developing and operating CO2 transport and storage facilities, as part of ‘Longship’, the Norwegian Government’s full-scale, carbon-capture-and-storage (CCS) project.

Northern Lights will create the first ever, cross-border, open-source, CO2 transport-and-storage infrastructure network, offering European companies the opportunity to store their CO2 safely and permanently underground.

Keeping carriers’ CO2 emissions to a minimum

Our dual-fuel ME-GIs will keep carrier emissions to a minimum in this project"

Wayne Jones OBE, the Chief Sales Officer and Member of the Executive Board of MAN Energy Solutions, said “We are delighted with our role in this ground-breaking project. With the current focus in the maritime world on reducing methane slip, our dual-fuel ME-GIs will keep carrier emissions to a minimum in this project, whose green credentials will be carefully examined.”

Wayne Jones OBE adds, “These vessels’ construction enables the revolutionary development of a flexible and efficient, European infrastructure for CO2 capture from industrial customers. I am convinced that the Northern Lights project has great potential for application across Europe.”

The newbuilding carriers will be used in the first phase of Northern Lights’ transport-and-storage-infrastructure development and are designed to transport liquid CO2 in purpose-built, pressurised cargo tanks.

Dual-fuel ME-GI engines

The dual-fuel ME-GI engines will mainly run on LNG, while other innovative technologies, such as wind-assisted propulsion system and air lubrication, will be installed to reduce carbon intensity by around 34%, compared to conventional systems. The ships are the first of their kind and have the potential to set a new standard for CO2 shipping on coastal trading routes.

The Northern Lights project allows for further phases to expand capacity through future investments triggered by market demand from large CO2 emitters across Europe.

Norcem carbon-capture project

Longship project aims to demonstrate that carbon-capture technology can be applied to larger industrial plants

The Norwegian Government’s Longship project aims to demonstrate that carbon-capture technology can be applied to larger industrial plants and set a new standard for future industrial projects.

The HeidelbergCement Norcem plant, located near Oslo, Norway, will be the first to use the Carbon Capture Heat Recovery technology (CCWHR), developed by MAN and Aker Carbon Capture, from the summer of 2024, when it will capture 400,000 tons of CO2 annually, corresponding to 50% of its overall emissions.

Compressed, liquefied gas

The gas will be compressed, liquefied and subsequently transported by Northern Lights, by use of the new carriers, to their onshore receiving terminal, located near Bergen in western Norway, from where a pipeline will lead to an underground storage location, in the North Sea.

Dr. Uwe Lauber, the Chief Executive Officer (CEO) of MAN Energy Solutions, said “CO2 emissions are currently unavoidable in cement production, with the sector accounting for almost 6 - 7% of the world’s carbon-dioxide emissions. This is why the cement industry is key on the road to a decarbonised future.”

Energy-efficient solution

Dr. Uwe Lauber adds, “We are very proud to be able to deliver such an energy-efficient solution for HeidelbergCement Norcem, which is the result of our successful pioneering work in the CCS field together with Aker Carbon Capture.”

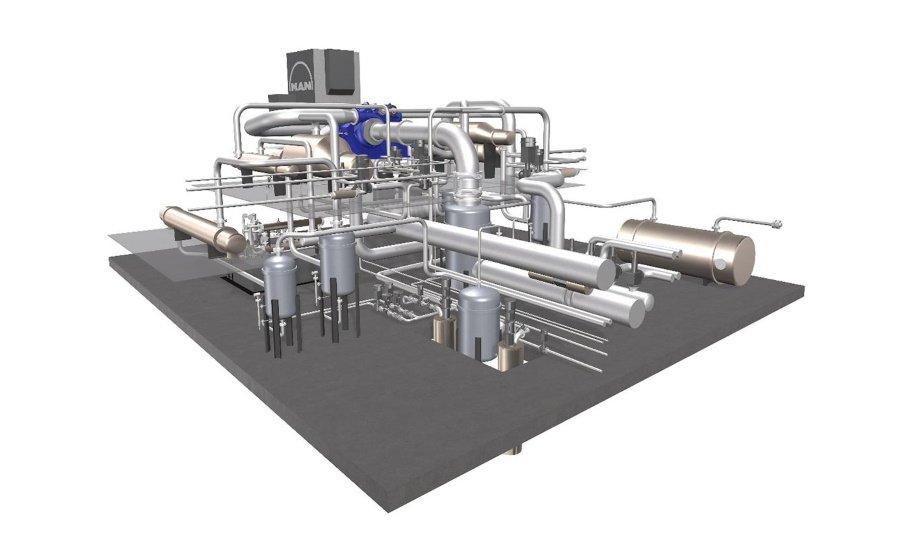

MAN Energy Solutions’ scope of supply for the cement factory includes an electrically-powered compressor train – Type RG 63-7 with integrated CCWHR technology, which allows the compression heat of the recovery compressor to be exploited. The steam generators cool the CO2 mixture between the compressor stages and generate steam that is, in turn, used for capture.