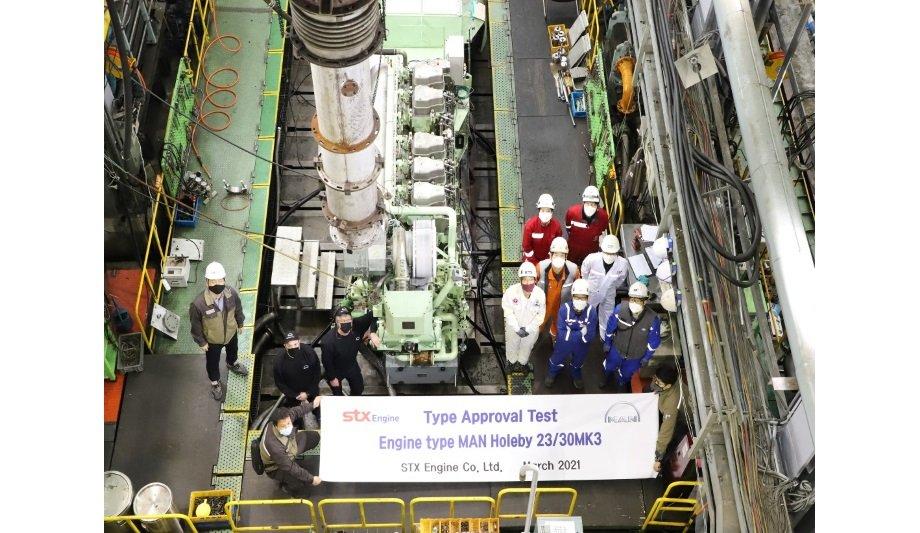

MAN Energy Solutions recently conducted a successful Type Approval Test (TAT) for a new engine, L23/30H Mk3.

Owing to current COVID-19 restrictions, the TAT was executed on-site in Korea in early March 2021 by STX and MAN Energy Solutions staff, with the classification team joining proceedings remotely. The event was filmed and broadcast globally with viewers watching from Europe, North America and Asia.

Major classification societies

Finn Fjeldhøj, Head of Small-Bore, Four-Stroke Engineering, MAN Energy Solutions, said: “TATs are an important step in the entry of every engine to the market. The fact that we could surmount the difficulties posed by the global pandemic with a remote solution to successfully get the engine approved is very pleasing. The experience gathered from this event will prove invaluable in the future.”

The experience gathered from this event will prove invaluable in the future"

MAN Energy Solutions’ Christian Rasmussen, Head of Classification Department, said: “Planning for the event began already in the summer of 2020 as a second wave of the virus hit and travel restrictions began to affect logistics. In response, we initiated a series of meetings with six major classification societies to investigate the possibilities for a remote type-test. Stemming from these, we developed a framework to successfully execute the TAT.”

Structure of remote tests

MAN Energy Solutions has also initiated a project with the classification society, ABS, to further refine the structure of remote tests. This particular project is expected to conclude during 2021, after which the company expects to have defined an optimal flow for remote TATs.

MAN Energy Solutions announced the first order for the new engine, even before the TAT, in February 2021 when STX Engine signed a contract with Daehan shipbuilding for 3 × MAN 6L23/30H Mk3 GenSets for 1+1 vessels. These engines will achieve Tier III emission levels with the aid of SCR, and are provisionally scheduled for delivery in August 2021.

Broad market penetration

The engine is mostly diesel-driven, with LNG and bio-oil also used in special environmental areas

The first 23/30H engine came on the market in 1965 and has a long history of operational stability. The engine is popular with shipowners for a number of reasons, not least for its broad market penetration that has ensured global recognition on account of its reliability and ‘forgiving’ service demands. Globally, well over 12,000 units have been produced over its lifetime.

Applications for the engine include tankers, bulk carriers and product tankers as auxiliary engines, with some sales as prime movers for fishing trawlers and power plants. The engine is mostly diesel-driven, with LNG and bio-oil also used in special environmental areas. The new Mk3 variant is a cost-effective GenSet that complies with 2020 SOx-regulations and has a power range of 500 - 1800 kW. Compared with its Mk2 predecessor, among other characteristics, it features:

- An increased power-output per cylinder.

- A reduced fuel-oil consumption.

- The longest TBO in its class.

- An improved conrod design.

- A two-part piston design for fast maintenance.