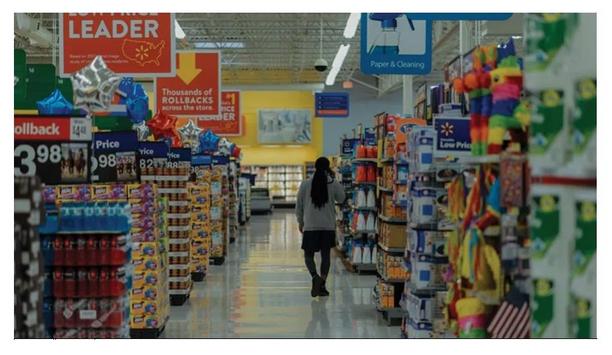

The retail industry is undergoing enormous change. The customers have evolved. They are demanding and selective. In these times, the retailers must review their existing supply chain setups and devise faster ways of reaching the markets.

Maersk’s customer, an iconic American retail brand, with over 500 stores across the US foresaw the possible implications of outdated processes and reached out to Maersk for a solution.

The challenge

The private labels’ supply chains were completely disconnected and were spending excessively

The customer’s stores stocked private labels and external brands. Each brand had vendors with their supply chain and logistics setup, wherein they sourced goods from multiple locations in China and consolidated at their distribution centre (DC) in Maryland, USA.

The customer would then pick up the shipment from Maryland, consolidate it at their distribution centre in New Jersey, and redistribute it to 16 DCs across the country, before stocking the store shelves. All this was just the process of bringing the goods of the external brands to the stores.

The private labels’ supply chains were completely disconnected. They sourced their items from around the world, delivered to the Maersk facilities, and then redistributed to the 16 DCs, before reaching the stores. In fewer words, the customer was spending excessively on fuel and trucking.

Integrated supply chain

Maersk evaluated several options for cost, volume, and time to the market. Finally, the winning solution was the integration of the customer's supply chain with the supply chains of the external brands. According to the new setup, the external brand vendor bypassed their distribution centre and shipped the goods directly to the Maersk facilities.

The customer could then consolidate this shipment with their own and distribute it further to their 16 distribution centres. After seeing the simplicity of the new process, the customer wanted their external brand partners on board, at the earliest.

Increased efficiency and cost savings

The newly integrated supply chain had strengthened the strategic ties between the customer and the external brands. Fewer touchpoints and faster time to the market had worked out to be great common benefits.

In terms of efficiency, the supply chain had gained 2.2 days per year, resulting in a higher provisional stock level and increased cash flow. Last but not least, the savings amounted to USD 1.1 million on inland transportation and working capital costs.