Brands have been expanding globally in search of new markets in recent years. In doing so, the demand for specialised warehouses and distribution centres has also grown. Companies require warehouses that are not only closer to production sites but also to their customers. This leads to lower costs and improved lead times.

With retail companies also focusing on e-commerce to target new customers, warehouses need to transform. They must become more multi-purpose-usage facilities that can handle single pieces as well as carton picking. They also need to take in fast-moving goods that are only stored for a few days on pallets.

The customer

The customer is among the UK’s leading retailers, with over 21 million people visiting their stores every week. The retailer works with over 2,000 suppliers globally and employs over 78,000 people in the UK and abroad. They own and operate over 700 stores in their home country, with 337 stores in 41 territories overseas.

The challenge

The company had to coordinate the distribution of goods from the UK to Europe, the Middle East

With suppliers spread out all over Southeast Asia, China and India, the customer required a specialised warehousing solution. The company was dispatching cargo from its Asian manufacturing centres to the UK, before forwarding it to final locations.

The company also had to coordinate the onward distribution of these goods from the UK to customers across Europe and the Middle East. All this led to a surge in container costs, operation time and weighed on its growth.

The company needed a new warehouse to store products from various manufacturing hubs across Asia. From there, it could forward those goods to its customers across the globe - without the need to channel them through the UK.

Warehousing & Distribution (W&D) solution

Maersk developed a Warehousing & Distribution (W&D) solution and established a Multi-Country Consolidation and Distribution Hub in Port Klang, Malaysia.

The retailer consolidated its entire inbound network and integrated it under the regional hub

The retailer consolidated its entire inbound network and integrated it under the regional hub, operated by Maersk. The centre would serve as the fulcrum connecting supply and demand. It also removed the need for goods to ship to the UK, transferring them directly to final points-of-sale or franchises.

The services implemented at the consolidated centre included:

- A warehouse management system with electronic data interchange (EDI) connectivity.

- Volume consolidation from various suppliers across the region.

- Pick and pack outbound shipments by pre-defined purchase orders and ship to final destinations within 7 to 10 days.

- Sorting e-commerce orders and forwarding them to distribution centres owned by online partners for faster processing.

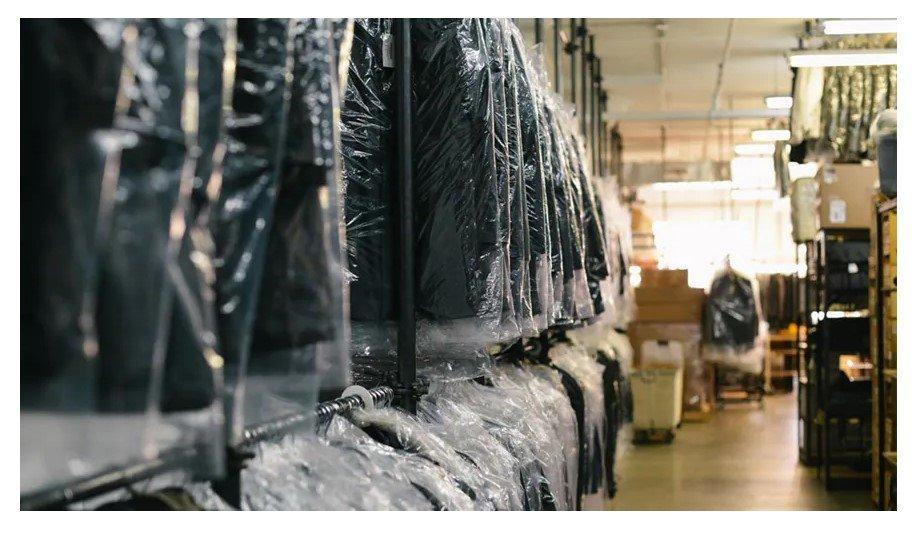

- Auxiliary supply chain functions include labelling, garments on-hanger, and tagging. This helped shorten go-to-market times or delay shipments depending on demand.

In addition, a complete solution encompassing a whole range of services – from consolidation and storage planning to customs clearance and freight management – was put in place to provide a comprehensive end-to-end logistics solution. This featured ocean freight, air freight, quality checking, and 4PL supply chain management.

Results

- Time savings through consolidation

- Reduction in costs through a single point of contact

As a result of the warehousing solution, the retailer was able to consolidate and achieve cost synergies at multiple levels:

- Consolidation of franchise orders and time savings by omitting the need for re-routing from the UK.

- Reductions in customer administration cost through a single contact point for freight and warehousing.

- Reductions in end-to-end container load spending from the origin, due to consolidation.

- Supply chain flexibility by product customisation services by final-destination requirements.

- Increase in operational scale by handling more units, larger consignments, and e-commerce shipments.

- Storage flexibility to hold cargo with different production cycles and franchise demands.