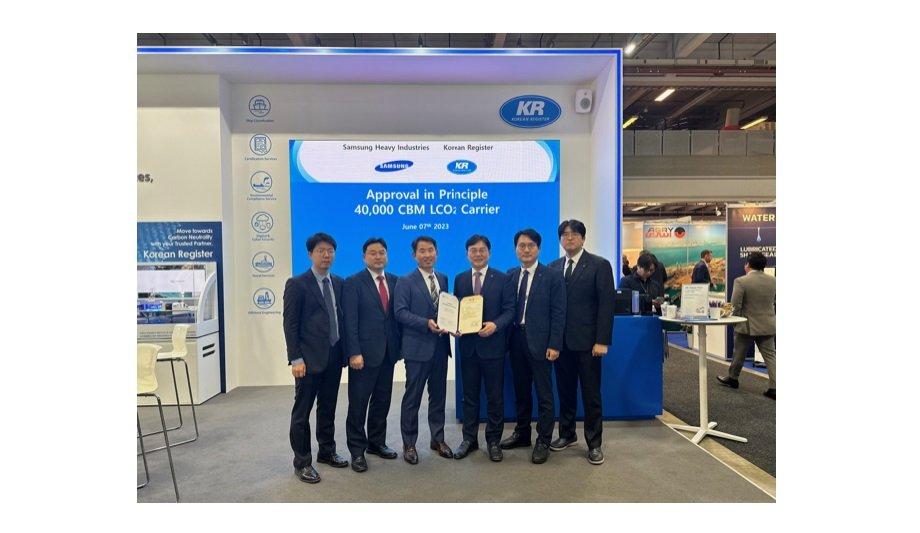

Korean Register (KR) has awarded an AIP (Approval in Principle) for a 40,000 m3 LCO2 carrier developed by Samsung Heavy Industries (SHI) in collaboration with KR.

Result of collaboration

The certificate was presented during a ceremony held at Nor-Shipping 2023 in Oslo, Norway on 7 June.

This achievement is the result of a successful collaboration between SHI and KR, with SHI designing the cargo tank and hull structure, while KR verified the suitability of the design by reviewing classification rules and related regulations.

LCO2 carriers

LCO2 carriers are expected to play an important role as a major means of transportation for CCUS

Among various technologies that have been developed to reduce carbon throughout the entire industry, LCO2 carriers are expected to play an important role as a major means of transportation for CCUS (Carbon Capture, Utilisation, and Storage) technology, which captures CO2 generated from fuel combustion or industrial processes, and either utilise it as a valuable resource or securely stores it underground, making a significant contribution to carbon reduction and global warming prevention.

Carbon dioxide (CO2) exists in a gaseous state at room temperature and must be maintained in a liquid state at low temperature and high pressure for mass transportation.

Economic efficiency

LCO2 carriers need to be designed to maintain optimal temperature and pressure for economic efficiency, and special attention is required to prevent phase change of CO2 during the operation of the vessels.

To maintain high pressure, the cargo tank of the LO2 carrier incorporates the IMO TYPE Independent-C tank.

Strength, durability, and reliability

Furthermore, the vessel is constructed using materials specifically engineered to withstand low temperatures, to secure sufficient strength and durability even in environments exposed to low temperatures.

Given that LCO2 has a higher density than LNG, more in-depth verification of structural safety for cargo holds, cargo tanks, and support structures is required. The LCO2 carrier has demonstrated reliability through structural analysis that evaluates structural strength and fatigue strength in high-stress areas.

LCO2 Carrier AIP

YEON Kyujin, Head of KR’s Plan Approval Center, said, “Through this LCO2 Carrier AIP, we have laid an important foundation for the commercialisation of large LCO2 Carrier technology."

YEON Kyujin adds, "We will continue to provide technical support for CO2 capture, storage and burial technology, and decarbonisation technology in the future.”

Eco-friendly technology

AHN Youngkyu, Vice President of SHI said, “Our LCO2 carrier is a good example of SHI’s advanced eco-friendly technology. We will dedicate ourselves to developing technologies to achieve carbon neutrality in the shipbuilding and maritime industry.”