Universal and equitable access to drinking water and adequate sanitation and hygiene services, as well as the improvement of water quality at a global level, are part of the Sustainable Development Goals of the 2030 Agenda for Sustainable Development, but they have also become part of a daily problem in many parts of the planet.

Ingeteam, with its Indar submersible pumps and motors designed and manufactured in Beasain, Spain, contributes to solve part of this problem; and among the numerous applications for which the submersible pumps and motors are intended are desalination plants.

Indar submersible pumps and motors installed

In this context, the six pumps and their corresponding submersible motors have been installed in the desalination plants of Alicante I and San Pedro del Pinatar I, both belonging to the Commonwealth of the Taibilla Canals, and their main task will be to take the water to be desalinated from the sea and discharge it as drinking water to the primary water network of the region, which in the summer period has more than 3 million inhabitants.

The desalination plants and their operation

The Alicante I desalination plant is located in Aguamarga, in the municipality of Alicante, Spain

The Alicante I desalination plant is located in Aguamarga, in the municipality of Alicante, Spain. It has a maximum production of 57,500 m³ of water per day and the treated water is fed into the New Alicante Canal (enlarged in 2006).

In this installation, 2 Indar pumps manufactured by Ingeteam have been implemented with their respective motors. These water collection units will work in coastal vertical wells which usually have a high variability of water level.

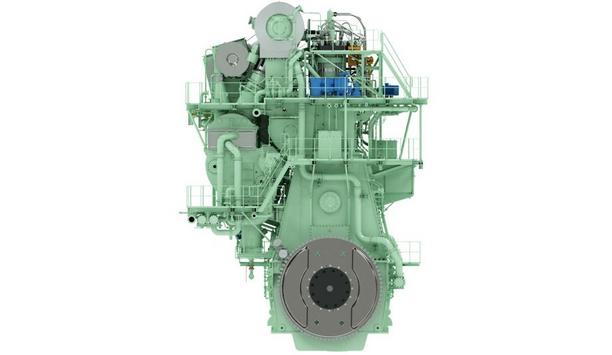

Seawater desalination plant using Ingeteam technology

The second seawater desalination plant using Ingeteam technology is called San Pedro de Pinatar 1. It is designed to produce and supply the Commonwealth with a daily volume of up to 65,000 m³ of drinking water.

The plant is located in the El Mojón area, near the Salinas and Arenales de San Pedro del Pinatar, in the Region of Murcia, Spain. The new units supplied will replace the 4 identical units supplied by the company in 2003.

Stainless steel units supplied

The 6 units for these desalination plants have been supplied to Ingeteam’s distributor, Juan Azcue, S.A., and are made of stainless steel, which is highly resistant to corrosion in aggressive environments, such as salinity, humidity, and acid or alkaline media.

Both plants take the water from the vicinity and then proceed to its treatment. Thus, the process includes a seawater pretreatment that guarantees its optimal conditions (physical and chemical); desalination as such, which is carried out by means of membrane racks; and finally, a seawater post-treatment that guarantees compliance with the criteria established for water for human consumption by the regulations in force.