The CO2 Efficient Transport via Ocean (CETO) joint industry project (JiP) concluded recently with the release of a report setting out the findings of the Technology Qualification performed in the study.

The project partners, which included Equinor, Gassco, Shell, TotalEnergies, and DNV, have found that there are no technological showstoppers to a low-pressure CO2 ship transport chain. CETO was funded by the project partners and Gassonova through the CLIMIT-Demo programme.

Carbon Capture and Storage (CCS)

For Carbon Capture and Storage (CCS) to play a significant role in helping the world reduce emissions, transporting large amounts of CO2 will be vital. Pipelines will be an option, but where the capture source and storage sites are unable to be easily connected, ship transport will be crucial.

To achieve the scale required for commercial viability, however, low-pressure ship solutions (approximately 7 bar at -49ºC) are regarded as an attractive alternative.

CO2 ship transport value chain

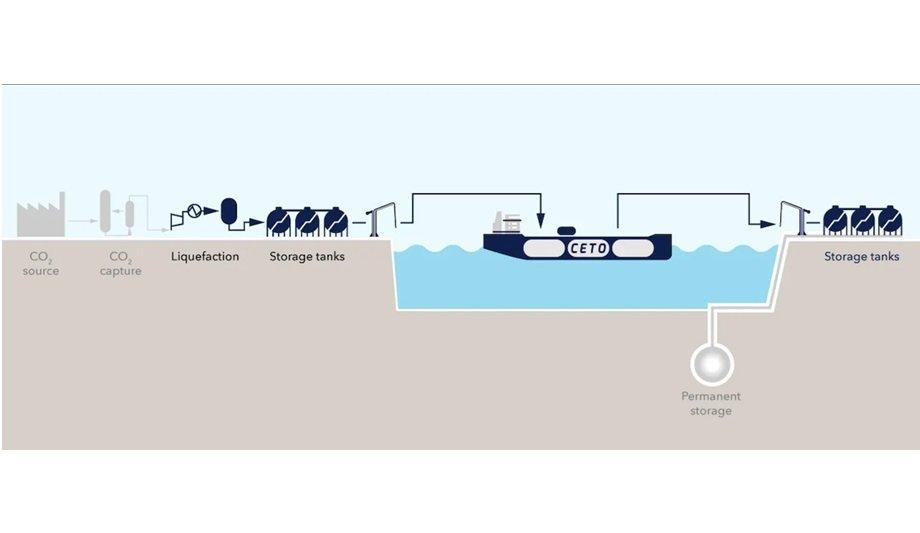

The project partners examined fundamental aspects of the CO2 ship transport value chain

During the Technology Qualification process, the project partners examined fundamental aspects of the CO2 ship transport value chain.

The production of liquid CO2, the characteristics and impurities in liquid CO2 that could affect transport, the plant concept, cargo handling, to the basic design of a 30,000 m3 Liquid CO2 carrier were all evaluated and assessed.

Testing campaign

CETO demonstrated that shipping CO2 at low-pressure conditions is feasible and that the technology is ready for first use. In terms of the vessel design, the activities show that a dedicated LCO2 carrier could be designed according to the relevant international rules and regulations, including the IMO IGC code and the DNV ship rules for global strength and stability.

The testing campaign on a medium-scale pilot plant demonstrated that cargo handling operations in the range of 6 to 9 barg could be carried out without dry ice formation.

Design accuracy and suitability

There were aspects of the transport chain that would require particular attention during project development

Finally, the accuracy and suitability of design process simulation tools were benchmarked with good agreement against experimental tests, and the benefits of dynamic process simulations on a full-scale design case were demonstrated.

However, there were aspects of the transport chain that would require particular attention during project development, such as material selection for cargo tanks, fatigue, and sloshing loads.

Low-pressure solution

Erik Mathias Sørhaug, Business Development Director CO2 Shipping at DNV, said, “It has been an honour for DNV to lead this JIP initiated by the four CCS pioneers, TotalEnergies, Shell, Equinor, and Gassco."

"The project has demonstrated that a low-pressure solution is technically feasible which again will enable low-cost transportation solutions for CCS projects.”

Economic viability

Lee Teng-Huar, General Manager of Maritime Operations, Asia Pacific and Middle East at Shell, said, “The conclusions from the CETO JIP signify a crucial milestone in advancing CCS technology."

"The optimisation of low-pressure liquid CO2 transportation can help bolster the economic viability of CCS initiatives and fast-track the ongoing journey towards a more sustainable and lower-carbon future for the industry.”

CO2 transport and injection capacity

Ola Miljeteig, Vice President, of R&D CCS solutions at Equinor, said, “Equinor is excited that the technology risks around low-pressure CO2 ship transport are now reduced."

"The low-pressure technology is relevant for reaching our increased ambitions of 30-50 million tons per year of CO2 transport and injection capacity by 2035.”

Comprehensive, optimal, and flexible transport

Svein-Erik Losnegård, Vice President of Research and Development at Gassco, said, “Gassco is pleased to contribute to the development of low-pressure CO2 ship transport technology and to see that the CETO project has succeeded in reducing the associated technology risks."

"Maturity and readiness of different transport solutions will be of great value in the establishment of a comprehensive, optimal, and flexible transport system in the CCS value chain.”

Carbon neutrality

Marie-Noelle Semeria, TotalEnergies Chief Technology Officer, TotalEnergies, said, “Bridging Carbon capture with storage or usage requires a safe and efficient CO2 transport by ship as an alternative to pipe."

"TotalEnergies is proud of the milestone demonstrated by the CETO Joint-Industry-Project covering the low-pressure CO2 transport chain evaluation and derisking assessment. This milestone paves the route of the company towards carbon neutrality together with the society.”