Indian engineering company Thermax Ltd has a long and successful history in the energy and environment sectors. The company’s growing business portfolio includes products for water & waste management, heating, cooling, and specialty chemicals.

They ship thousands of tonnes of specialist cargo all over the world and have been one of Maersk’s biggest Beneficial Cargo Owners (BCO) across India, Bangladesh, and Sri Lanka over the past year.

The challenge

Special cargo logistics

Given the complex nature of special cargo logistics, the company was navigating through multiple challenges to transport their cargoes seamlessly.

Maersk is always on the watch to help ease the weight of logistics needs for its customers. So, when Thermax had a special project in San Juan, Puerto Rico, Maersk jumped at the opportunity to support them.

Transportation of chillers

The company was looking to transport chillers to ensure that they travel safely to their destinations

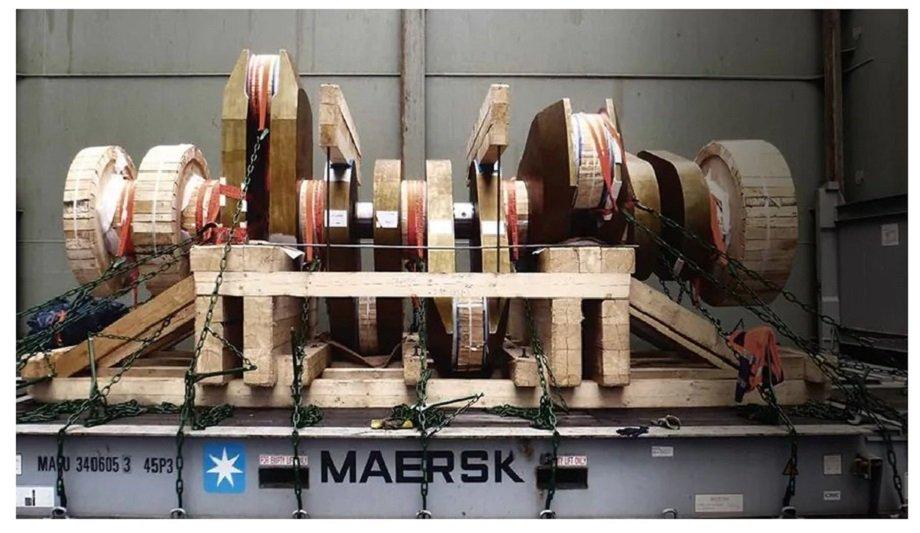

The company was looking to transport chillers – high-value equipment used in industrial refrigeration, air conditioning, and process cooling & heating. These massive machines weigh more than 44 tonnes and need to be handled by technical experts to ensure that they travel safely to their destinations.

Thermax had been discussing the transportation with Maersk for over a month. Right from the start, several challenges presented themselves.

Offloading partners

Thermax preferred stuffing their Over-Dimensional Cargo (ODC) at their factory but wanted a reliable partner to help offload the units, lashing, and other pre-freight onboard processes.

However, the cargo was larger, in both weight and dimensions, than what could safely be transported from their factory to the Kattupalli (INKAT) port in Chennai. This prevented stuffing on-site and meant securing heavier hauling equipment. They were also aware of restrictions at the railway barricade at INKAT, which could potentially disrupt the smooth travel of the cargo through the port.

The solution

Container Freight Station (CFS) solution

Maersk's teams removed the railway barricade at INKAT to ensure the freight train moved through smoothly

Maersk’s team of special cargo experts took careful note of all the parameters and proposed a solution that combined our road, ocean, and cargo handling services. Its first move was to plan and execute a detailed survey of the route and offer a Container Freight Station (CFS) solution along with road freight.

Maersk secured a low-bed trailer to transport the units from Thermax’s factory to the CFS and procured cranes, additional lifting equipment, and extra lashing belts to handle the heavy cargo along its journey to the terminal. Working in close coordination with the terminal, Maersk's teams also removed the railway barricade at INKAT to ensure the freight train moved through smoothly without its large-sized cargo being impacted in any way.

The result

Cost-effective solution

Despite last-minute hiccups and challenges that threatened the seamless transportation of the cargo, the units made it to their ship on time and in mint condition. Maersk met its promise of a cost-effective solution and negated risks for Thermax with the oversized cargo being escorted from factory to terminal.

Thermax was thrilled with the support from Maersk's teams, who planned and executed the delivery of cargo, while also helping troubleshoot challenges on site. The operation helped further strengthen its partnership, which now looks set to scale greater heights.