B.F.E. Bonney Forge is one of the first European companies to secure certification for a spare part intended for field operations through the application of AM technology.

This achievement signifies a major milestone in the manufacturing landscape, one that demonstrates the potential of this innovative technology to reshape the future of pressure equipment under the Pressure Equipment Directive 2014/68/EU (PED).

CE-certified pressure vessel

The collaboration builds upon the successes of the same Shell team that, in 2021, unveiled the world's first CE-certified pressure vessel, albeit for research and development purposes. The fruitful partnership with B.F.E. Bonney Forge paves the way for the future certification of functional pressure equipment manufactured with AM technology.

The initial 2021 valve set a high bar with its exceptional performance across all metrics. Inspired by this success, Shell and B.F.E. Bonney Forge embarked on an innovative journey to create a gate valve with an unprecedented design, all thanks to cutting-edge AM technology.

Particular Material Appraisal (PMA)

This gate valve earned a certificate of full quality assurance, demonstrating compliance with the stringent standards

DNV is a recognized authority in the pressure equipment field and bestowed the gate valve with the Particular Material Appraisal (PMA). This appraisal, granted by a notified body, signifies authorization for the use of a material that was not initially covered by a harmonized standard.

As a result, this gate valve earned a certificate of full quality assurance, demonstrating compliance with the stringent standards set by the Pressure Equipment Directive 2014/68/EU.

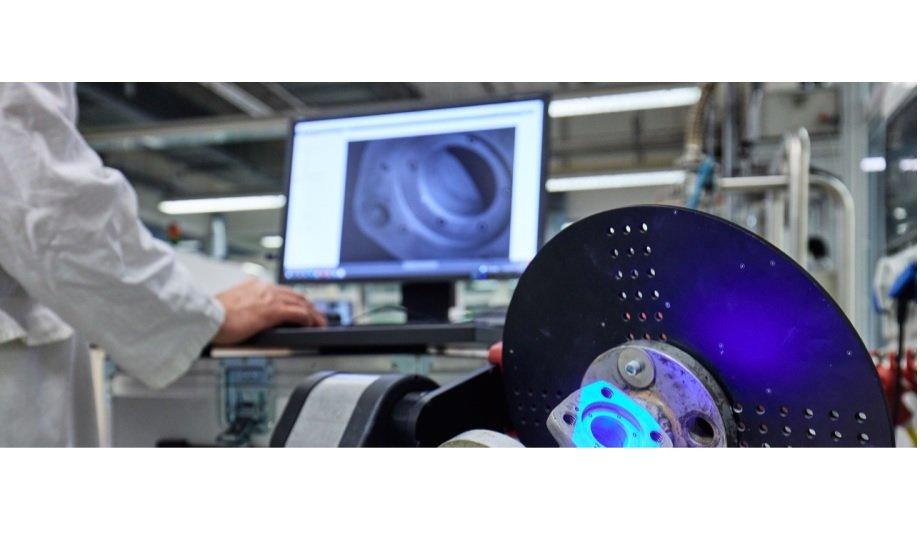

AM technology

The destination of this gate valve is the Shell Energy and Chemicals Park Rotterdam, where it will be installed. This pioneering work is poised to showcase the myriad benefits and, more importantly, the safety associated with valves manufactured using AM technology.

It sets the stage for the commercial production of pre-qualified pressure components with AM technology, assuring adherence to rigorous quality standards. These components will play a pivotal role in ensuring the safe operation of equipment within the energy sector.

Safer, more innovative future

Maurizio Bellina, Head of Product Assurance – Europe at DNV Supply Chain & Product Assurance, said, “We would like to congratulate Shell as it continues to be a pioneer in additive manufacturing research and development, and B.F.E. Bonney Forge which has proven to be the trusted partner when applying AM technology to pressure accessories."

“We extend our congratulations to everyone involved in this monumental technical achievement. This feat not only redefines the possibilities of AM technology but also propels the industry toward a safer, more innovative future. We look forward to witnessing the transformative impact of this 3D printed gate valve in the energy sector and beyond.”