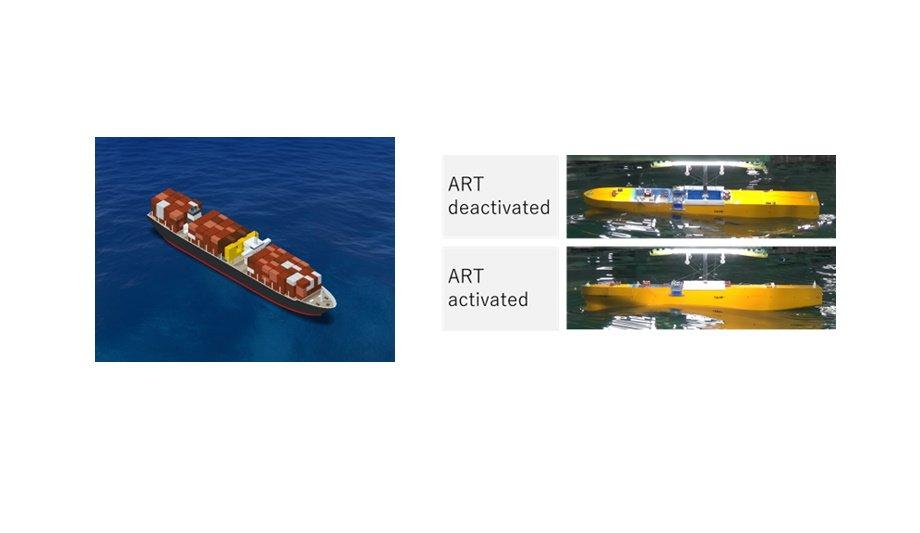

ClassNK has signed a joint R&D agreement with Nihon Shipyard Co., Ltd. (NSY) and IMC Co., Ltd. (IMC) to ensure the safety and performance evaluation of anti-roll tanks (ART) installed on large container ships.

An anti-roll tank is a device designed to suppress the ship's roll by moving liquid, such as water, within the tank. Consideration for ART installation on large container ships is advancing due to the expectation of improving container loading efficiency by reducing roll motion and preventing parametric roll, which is regarded as one of the causes of container collapse accidents.

ClassNK signs joint R&D agreement with NSY and IMC

ClassNK confirmed their anti-rolling effect against parametric and synchronous roll, and collected data

ClassNK has established the requirements in its ‘Guidelines on Preventive Measures against Parametric Rolling (Edition 1.0)’ to grant a notation to the ship equipped with ART. Additionally, through a tank test of ART-related R&D conducted in 2023, ClassNK confirmed their anti-rolling effect against parametric and synchronous roll, and collected data.

For expanding the application of ART to large container ships, NSY, a world renowned company in the development of large container ships, IMC, which has extensive experience in the design and sales of ART, and ClassNK have signed this joint R&D agreement.

Safer application of ART and performance evaluation

Utilising the obtained data and knowledge, each party will collaborate to ensure the safer application of ART on an actual ship and performance evaluation.

The roles in the joint R&D are as follows:

- NSY - Design of optimal installation plan of ART on large container ships.

- IMC - Demonstration of ART's reduction effect on ship’s roll.

- ClassNK - Establishment of appropriate evaluation methods for ART Updating guidelines and regulations with more practical and concrete requirements.

ClassNK contributes to safe operation of container ships

ClassNK will continue to strive for contributing to the safe operation of container ships through establishing standards with utilising outcomes obtained by collaboration with industry frontrunners.