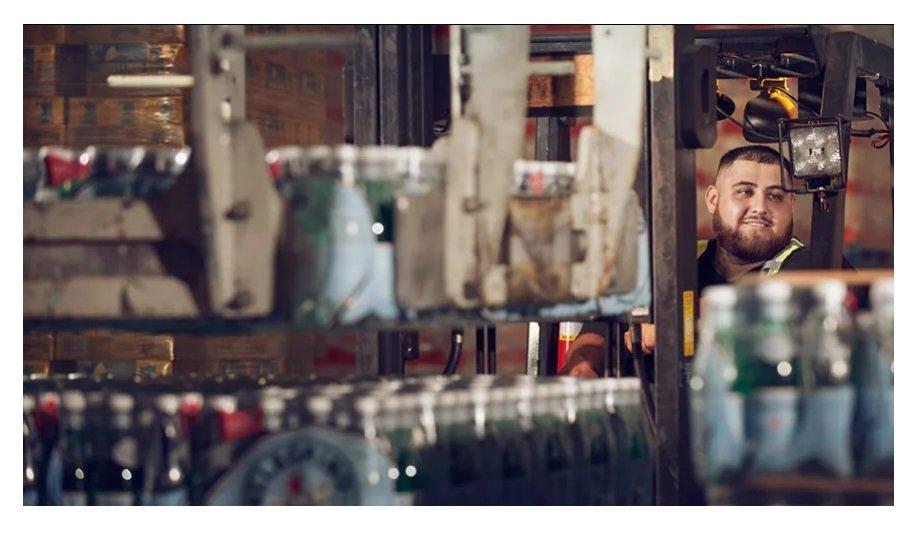

Being one of the world’s leading bottled water companies, the customer has over 95 production sites in 34 countries, employing more than 20,000 employees worldwide. They own several unique brands across Asia, Europe, and the Americas.

The Challenge

The customer was experiencing high shipping costs and quality issues caused by heavy cargo weights and underutilised containers. Only 55-60% of the container space was fully utilised because cargo loaded at the origin was reaching maximum weight.

The customer faced a problem with being able to monitor their cargo closely.

The problem of underutilisation created void spaces inside the container, which meant that the cargo would move while on transit and be damaged on arrival. Questionable quality assurance led to poor customer service performance.

Additionally, the customer faced a problem with being able to monitor their cargo closely. Different products within their line of range demanded unique warehousing requirements. A logistics provider who could adopt different processes for different products was in need.

Heavy Weight Zone program

Maersk offered a ‘Heavy Weight Zone’ program allowing containers to exceed the general weight restriction, where the customer’s cargo is moved by a special triaxle truck from ports and terminals to a local warehouse for deconsolidation.

This approach lets suppliers and distribution centres load more volumes into containers to ensure more secure transit. The warehouses offered tailor-made value-added services, delivering effective quality assurance to meet predetermined performance indicators.

Reduced shipping costs

The customer can ship on average 21 pallets per container at 58,000 lbs

Significant reductions in shipping costs and reduced ocean spending by approximately 30%, caused by the maximisation of container capacity. The customer can ship on average 21 pallets per container at 58,000 lbs.

The new warehouse protocols reduced the damage by 8% per year and increased the fill rates to wholesale and retail consumers. Previously, the customer was able to ship only at fright standard, which were only 14 pallets in each container.

The savings in annual shipment costs are equivalent to shipping 3,250 containers. In addition, the lower number of ocean shipments has reduced the carbon footprint in line with the customer’s global sustainability goals.