Where winters are harshest, the toughest technology is required for marine operations to continue uninterrupted during the frozen months. For 30 years, Azipod® propulsion has proven to be up to the task, keeping harbours open and moving goods and people through the most challenging sea ice conditions on the planet.

A revolution from the start, Azipod® technology has continued to break new ground, or ice, throughout its lifetime. More than 90 ice-going vessels equipped with Azipod® propulsion are sailing today, representing a steadily evolving series of innovations in power and performance.

High-speed and lesser power

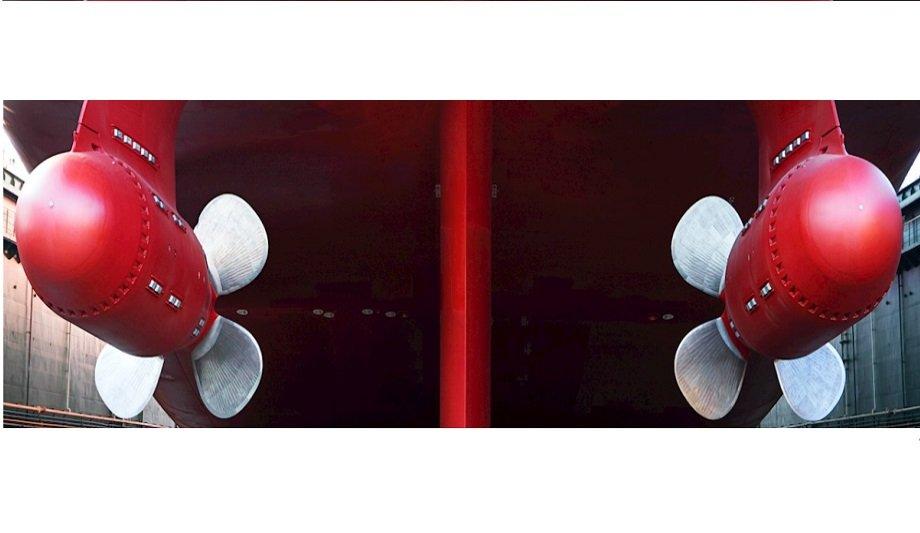

Icegoing ships powered by Azipod® propulsion can operate with the so-called Double-Acting ship capabilities, running ahead in open water and astern in heavy ice conditions.

Propellers mill the underwater part of the ice ridge to open a passage allowing the ship to move ahead

Propellers mill the underwater part of the ice ridge to open a passage; water flow generated by the propeller flushes the hull, allowing the ship to move ahead with ease. This capability allows ships to navigate in ice-covered seas without icebreaker assistance while keeping higher speeds and consuming less power.

“Vessels with fuel-efficient Azipod® propulsion can keep ice channels open more effectively than conventional icebreakers with shaft line propulsion, allowing ships following behind to use less fuel as well. Emitting zero pollutants to the sea, Azipod® propulsion leaves nothing in its wake but open water,” said Sakari Sorsimo, Head of the Ice Segment, ABB Marine & Ports.

Conceived for the cold

The idea of a steerable propulsion unit was conceived in Finland in the 1970s, primarily with icebreaking in mind. Ice tests at Kvaerner Masa Yards in Helsinki helped engineers to understand the advantages that steerable propulsion could provide to ice-going vessels, in addition to icebreakers.

The ice-going waterway service vessel Seili became the first ship to be powered by Azipod® propulsion in 1991. In 1993, the tanker Uikku was fitted with Azipod® propulsion. Due to her remarkable icebreaking capabilities, she became the first non-Soviet merchant vessel to navigate the entire Northern Sea Route in 1997.

Enticed by the success of Uikku, the Russian mining company Norilsk Nickel began investigating the use of icebreaking bulk ships to avoid costly icebreaker escort fees. Investment in the new technology paid off, eliminating the need for icebreaker assistance when they entered service in 2006.

Supplying propulsion systems

Azipod® propulsion strongly contributed to the vessel’s successful passage while facing challenging conditions"

Further technical and commercial developments followed, and in a milestone contract in 2014, ABB has secured an order to supply electrical power and propulsion systems for a fleet of 15 specially designed tankers transporting liquefied natural gas (LNG) year-round from one of Russia’s most significant export developments in a generation – Yamal LNG.

The fleet’s 300-meter Christophe de Margerie, the world’s first icebreaking LNG carrier operated by Sovcomflot, made the Northern Sea Route crossing in 19 days without the aid of an icebreaker in 2017. “ABB Azipod® propulsion strongly contributed to the vessel’s successful passage while facing some of the world’s most challenging ice conditions,” said Igor Tonkovidov, President and Chief Executive Officer, Sovcomflot, SCF Group.

Cost-savings

In 2020 ABB extended its string of orders to the Arctic LNG trade, with a contract to deliver power and propulsion to six new LNG carriers for transporting gas along the Northern Sea Route. Scheduled to enter service in 2023, each of the six new build ARC7 class vessels will feature a trio of the largest and most powerful Azipod® propulsion units ever supplied for ships operating in ice. Each propulsion system will have a total capacity of 51 MW, which is comparable to a nuclear-powered icebreaker.

The Northern Sea Route represents one of the planet’s vital shipping arteries. Offering 30 percent faster passage than the southern Europe-Asia alternative via the Suez Canal, the Arctic alternative is attractive for the fuel and emission savings it offers.

Groundbreaking icebreakers

Polaris was equipped with three Azipod® thrusters, two on the stern and one in the bow

Dubbed “the world’s most environmentally friendly icebreaker” upon its commissioning in 2017, Polaris, the world’s first icebreaker powered by LNG, was equipped with three Azipod® thrusters, two on the stern and one in the bow.

Polaris Master Pasi Järvelin praised the vessel’s performance after its first months at sea, “Polaris is much more agile than any other icebreaker. This is not only due to the dual aft Azipod® thrusters, but also the bow-mounted Azipod® unit, which has proven to be an excellent aid for maneuvering in ice.”

In 2018 the Xue Long 2 research vessel became the first icebreaker to be built entirely in China, equipped with Azipod® propulsion. “Two key goals for the Xue Long 2 were maximum flexibility and durability,” said Rong Huang, Chief Engineer, and Designer of the Polar Research Institute of China. Speaking about Azipod®'s propulsion, he added that the system ensured the new vessel’s ability to carry out her missions in varying Arctic and Antarctic ice conditions “with the highest possible regularity.”

Azipod-powered ship

Equipped with twin 5MW Azipod® icebreaking units, in 2019 the Norwegian Coast Guard vessel KV Svalbard became the first-ever Azipod-powered ship to reach the North Pole, on a mission to map changing water temperatures in the Arctic.

“Keep in mind that this is the region with the most extreme ice conditions on the planet. The success of the mission was a major accomplishment given the physical and environmental parameters,” stated Andreas Kjøl of the Norwegian Coastal Administration.

Robust propulsion system

ABB secured a contract to equip the first US Coast Guard Polar Security Cutter (PSC) with Azipod® propulsion "We were able to navigate through the Arctic waters and reach the North Pole faster than we thought possible," reported Ottar Haugen, Norwegian Coast Guard commander. “This was a significant milestone for us and proof that we have a vessel in our fleet equipped with a robust propulsion system that enables operations in the harshest ice conditions – all the way to the North Pole."

Equally popular on the other side of the Atlantic, in 2019 ABB secured a contract to equip the first US Coast Guard Polar Security Cutter (PSC) with Azipod® propulsion. The new vessel represents a continuation of 15 years of successful operational experience from the USCG Great Lakes Icebreaker Mackinaw, equipped with two Azipod® units.

Proven performance, sustainable future

The fuel and emissions-saving capabilities of Azipod® electric propulsion have made it the technology of choice for ice-going and icebreaking vessels for 30 years.

“We are committed to supporting the growing Arctic maritime industries with our unparalleled technology that has over the years proven to enable safe, sustainable operations and ensures year-round transportation of cargoes across the Northern Sea Route,” confirms Juha Koskela, Division President of ABB Marine & Ports.