For instance, a company may meet critical deadlines by flying its COVID-19 vaccine to those hit by another wave of the pandemic. Conversely, for the planned global rollout of billions of doses of the vaccine, the same company may want to ship its product across continents.

The question is, are today’s carriers equipped to transport the most fragile, high-value, regulated cargo in the world?

The evolution of Ocean logistics for Pharmaceuticals

Transporting high-value cargo over long distances with zero room for error is a complex affair, only to be made more challenging by the multiple audits imposed by Pharma companies and regulators. Ocean solutions play the role of a ‘floating warehouse’ for manufacturers

Over the years, however, supply chain solution providers have taken a strategic approach to minimise logistics risks on the ocean. At the heart of this approach is a commitment to complete supply chain transparency using integrated digital platforms and visibility tools. With such solutions, logistics service providers are now able to put control back into the hands of Pharma businesses by enabling them to take real-time decisions that prevent issues and minimise the loss of their sensitive cargo.

More recently, the industry has identified the need for new inventory models that shock-proof their businesses. Here too, Ocean solutions play the role of a ‘floating warehouse’, enabling manufacturers to supplement their just-in-time with just-in-case (safety stock) inventory strategies.

But is this enough for Pharma companies to substantially increase Ocean’s share in their modal mix?

Ocean transportation is reliable

Historically, companies have tried to overcome the complexities of running a Pharma supply chain with speed – the faster one takes a product from A to B, the fewer errors one is likely to experience along the way. Unfortunately, this isn’t always the case. Pallets are vulnerable to temperature deviations and contamination on the tarmac, especially if there are multiple handoffs and handling of the product.

Refrigerated containers, on the other hand, can take a Pharma product from production to patient with minimal handling, as the door of the container need not be opened at all. Remote container visibility and monitoring help Pharma manufacturers stay ahead of possible issues. And proactive issue handling prevents temperature deviations from resulting in loss of the product. It should come as no surprise then that ocean-related excursions amount to less than 1% of all excursions in one journey.

Ocean logistics - products accessible to everyone

Ocean transport makes vaccines affordable as it is approximately 78% less expensive than Air transport Today, 30-40% of the cost of a vaccine can be attributed to its transportation. Yet, the need to keep quality, care and service levels high have always put the reduction of logistics costs on the back seat. Not anymore.

Companies aiming to make the COVID-19 vaccine accessible to middle and low-income families around the world are now looking for ways to keep their vaccines affordable. Ocean transport makes this possible as it is approximately 78% less expensive than Air transport.

Ocean solutions are sustainable

Air transport emits 1,000 gm of CO2 per kg of products per 1,000km. In comparison, Ocean transport emits only 40 gm of CO2 per kg of products per 1,000km. That means increasing the role of Ocean in the modal mix can reduce the carbon footprint by up to 1/25 times per journey, improving brand reputation a great deal.

Ocean - a viable option for Pharma companies

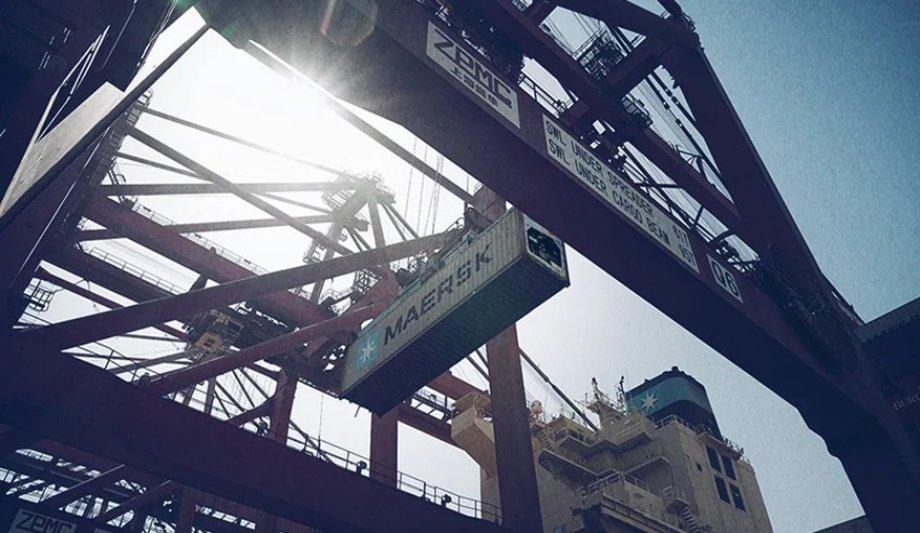

International Pharma companies approach Maersk because of the extensive network, the 80+ years of experience in refrigerated cargo transportation, and the fleet of 360,000 containers (the largest in the world). Companies sign up with Maersk because they believe the Reefer excellence team and the end-to-end portfolio of logistics solutions including Air Freight, Inland, Warehousing and Distribution, and real-time data solutions can simplify and connect their supply chains.

Companies remain partners with Maersk because they go all the way to protect the integrity of their products by improving infrastructure at terminals, ensuring faster handovers, planning last-mile flows more efficiently, and providing complete transparency throughout the cold chain.