MAN Energy Solutions’ Two-Stroke Business has announced that it has surpassed 2,000 orders for IMO MARPOL Annex VI NOX Tier III-compliant technologies for its portfolio of MAN B&W two-stroke engines.

The new milestone occurs just over a year after the company announced the passing of the 1,000 milestones in January 2021.

Prioritise environmental considerations

Bjarne Foldager – Senior Vice President and Head of Two-Stroke Business – MAN Energy Solutions, said: “This welcome milestone is built on the experience we have gathered over the past decade. Our fully-mature EGR and SCR systems deliver Tier III NOx-compliance and improve engine performance in terms of increased fuel efficiency and lower, general emissions. Our ability to treat a ship as a complete system gives us a clear market advantage that enables us to prioritise environmental considerations and system integration.”

Among other statistics, MAN Energy Solutions reports:

- Determined by bore size, 50- and 60-bore MAN B&W engines account for most NOx solutions (37%);

- EGR accounts for 724 vs 1,292 SCR solutions.

Furthermore, the company reports that some 67 engines were equipped with EcoEGR, representing about 9% of all EGR solutions. EcoEGR is a tuning method that lowers fuel consumption by recirculating a small amount of exhaust gas while operating in Tier II.

Optimising engine performance

MAN Energy Solutions is rightly proud to have brought three technologies – in the form of EGR"

Foldager added: “Considering how NOx Tier III limits were only introduced in 2016, shipping has come a long way in a short period of time. MAN Energy Solutions is rightly proud to have brought three technologies – in the form of EGR, and low- and high-pressure SCR variants – to market such that every owner and ship designer can select what best fits their individual project.”

In relation to EGR, Stig B. Jakobsen – Senior Manager, Two-Stroke Operation – MAN Energy Solutions, said: “More than ten years of service experience with our EGR design has enabled us to introduce refinements and optimisations. The latest design is a perfect example of such optimisation since we employ our fourth-generation EGR in our low-pressure, dual-fuel ME-GA engine. EGR has become an integral tuning tool for each of our low-speed engines and its maturity will allow us to further explore the potential for optimising engine performance well into the future.”

After-treatment process

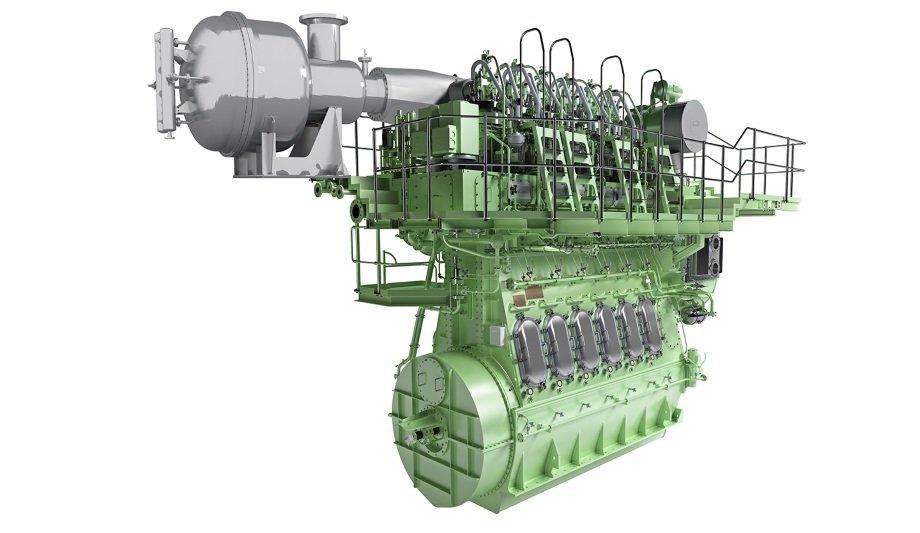

Exhaust Gas Recirculation (EGR) prevents the formation of NOx by controlling the combustion process, while Selective Catalytic Reduction (SCR) uses a catalyst and an additive to remove the NOx generated by the combustion process as an after-treatment process.

MAN Energy Solutions offers both EGR and SCR as proprietary NOx solutions

Uniquely for the two-stroke sector, MAN Energy Solutions offers both EGR and SCR as proprietary NOx solutions. The company has long experience with EGR technology and reported its first order already in 2011, while its own in-house-developed SCR-HP (-High Pressure) won its first order in January 2019.

Methanol-carrier segment

This features a drastically reduced reactor-size, compared to rival systems, to which MAN Energy Solutions has been providing system approval since 2014.

Methanol-fuelled, MAN B&W LGIM engines have a special feature as explained by Kjeld Aabo – Director of New Technologies – MAN Energy Solutions: “Through the use of water emulsion in the methanol, we are able to reach Tier III levels in methanol fuel-mode, completely removing the need for a dedicated NOx-abatement technology. Our introduction of this on our G50-LGIM engine gains us highly valuable service experience – especially in the methanol-carrier segment – while we see a very clear demand for full Tier III-compliance across all fuel types outside this segment by means of EGR.”