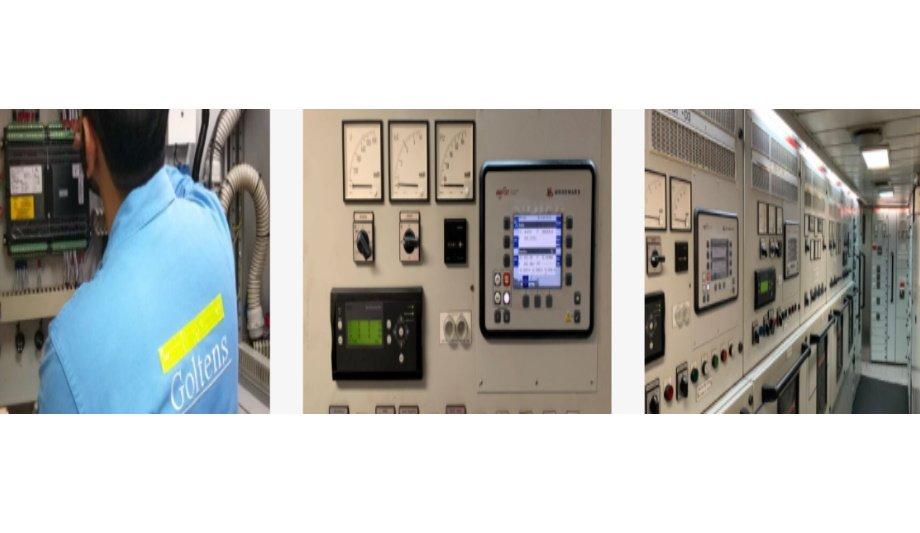

Goltens upgraded three generator set controls on an offshore supply vessel. For each generator, the Woodward easYgen 3500XT P2 replaced the combined functionality of the obsolete Woodward DSLC/828 and Protection Relay. The upgrade corrected problems that had built up over time and simplified and reduced the operator interfaces while improving reliability and diagnostic capabilities.

Multiple user-interfaces

Two generators are dedicated to their respective Port and Starboard busbars, the third having two breakers to allow Port or Starboard feed. A coupler connecting the two busbars is normally closed and can be opened manually.

The existing system comprised of 3 sets of Woodward DSLC and Generator Protection Relay which were used to manage the synchronisation of the 4 breakers, and the load-sharing and generator protection requirements of the system.

The DSLC’s communicated with each other over LON and to a Woodward 828 controller which used custom software to supervise the different operating modes. All these controls had their own interfaces, some in the form of Handheld Terminals (HHT), and each unit was hardwired to the ship’s management system.

Single intuitive user-interface

The system reliability is improved as the number of controllers was reduced from 7 to 3

Three Woodward easYgen 3500XT P2 very easily replaced the DSLC, 828, and Protection Relay system by combining the power management, engine-generator control, and protection functions. The multiple user interfaces were replaced with a single intuitive user interface allowing monitoring of genset parameters at a glance, enabling the operator to make informed decisions.

The system reliability is improved as the number of controllers was reduced from 7 to 3 and with the use of a redundant peer-to-peer network between the easYgen controllers.

A documentation package was provided to the customer to submit to the classification society for approval.

Reduced operation costs

Goltens’ team was successful in replacing 7 controllers with just 3 Woodward easYgen 3500XT P2 without sacrificing the operational philosophy. The vessel is fully operational with improved system control and reliability and spares requirement cut by more than 50%.